Paddle Impeller Manufacturer in India

SV Industries, located in Ahmedabad, Gujarat, is a leading manufacturer and supplier of paddle impellers, trusted by industries across India for their superior design, performance, and reliability. Known for its dedication to providing the highest quality industrial products, SV Industries ensures that every paddle impeller we manufacture is engineered to meet the most demanding applications. We have earned a solid reputation as a supplier of paddle impellers to various sectors, including chemical processing, pharmaceuticals, food and beverage, and water treatment, serving regions such as Gujarat, Rajasthan, Maharashtra, Madhya Pradesh (MP), Uttar Pradesh (UP), and Bihar.

At SV Industries, we specialize in providing customized mixing solutions for our clients. Our paddle impellers are designed to deliver optimal performance while ensuring energy efficiency and minimal maintenance. Whether you’re mixing low- to medium-viscosity fluids, suspending solids, or blending different materials, our paddle impellers are ideal for achieving uniform, consistent results.

What is a Paddle Impeller?

A paddle impeller is a type of mixing device used in industrial processes to mix liquids, suspensions, and slurries. The paddle impeller features broad, flat blades that resemble paddles, and it operates at moderate speeds to move and blend liquids gently. Unlike high-shear impellers, which operate at high speeds and create strong turbulence, the paddle impeller is designed to create a uniform, low-energy flow that is ideal for mixing low- to medium-viscosity fluids without damaging the product. Paddle impellers are commonly used in applications where delicate mixing is required, and they are especially effective for suspending solids in liquids or creating homogeneous mixtures of various substances.

How Does a Paddle Impeller Work?

The primary function of a paddle impeller is to move liquid in a tank or vessel by gently pushing the fluid around. The flat blades of the paddle impeller create a low-shear, high-flow pattern that mixes liquids and suspends solids. Paddle impellers work by rotating at moderate speeds, causing the liquid to circulate in a circular motion. As the impeller turns, it forces the liquid toward the walls of the tank, where the liquid then moves back toward the centre, creating continuous agitation. This action prevents solid particles from settling at the bottom of the tank, ensuring that the mixture remains homogeneous.

One of the key features of a paddle impeller is its low shear rate, meaning it can mix fluids without creating excessive turbulence or damaging sensitive materials. This makes it ideal for applications such as pharmaceutical production, where preserving the integrity of active ingredients is crucial, or in the food industry, where a gentle mixing action helps maintain product quality.

Design Features of SV Industries Paddle Impeller

At SV Industries, we pay close attention to the design and construction of our paddle impellers to ensure maximum efficiency, durability, and ease of use. Key design features of our paddle impellers include:

High-Quality Materials

We use stainless steel and corrosion-resistant alloys to construct our paddle impellers, ensuring they are durable, long-lasting, and resistant to harsh chemicals and abrasive materials.

Customizable Blades

Our impellers can be customized with different blade configurations to suit specific mixing requirements. Whether you need a large diameter for a high-volume tank or a specific blade angle for optimal flow, we can tailor the impeller to your needs.

Optimized Blade Design

The broad, flat blades are engineered to create efficient mixing with minimal power consumption, ensuring that the impeller performs well even in low-speed, high-viscosity applications.

Durable Construction

Our paddle impellers are designed for continuous use, with robust construction that can handle even the toughest industrial environments without frequent maintenance or downtime.

The combination of these design elements ensures that SV Industries’ paddle impellers provide the highest performance, longevity, and versatility across a wide range of applications.

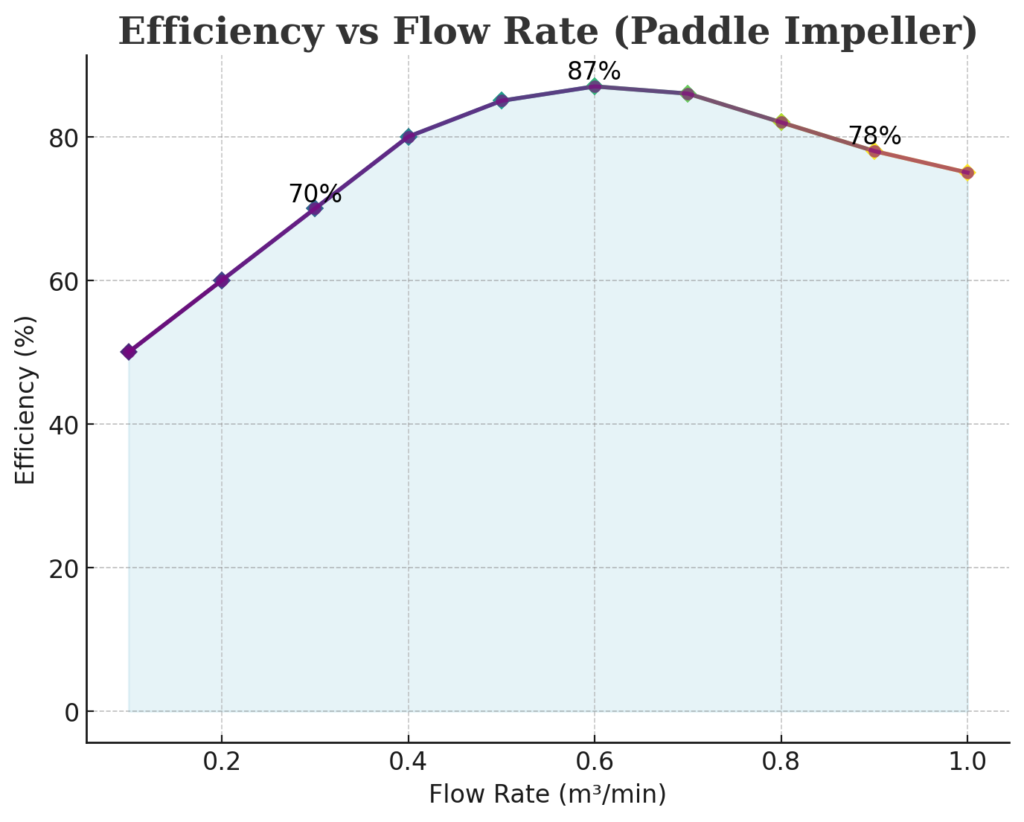

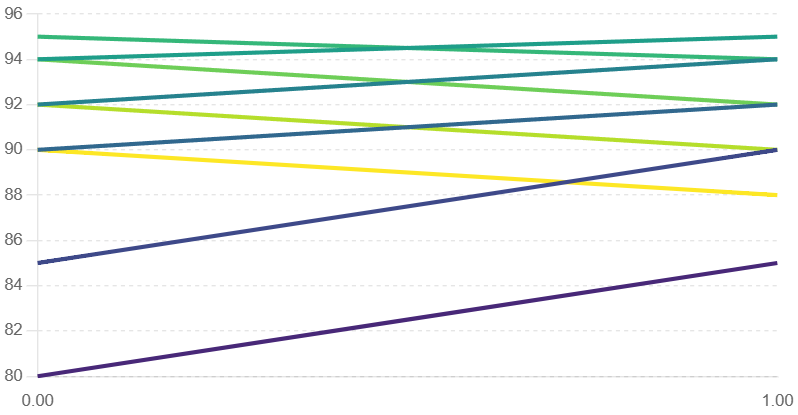

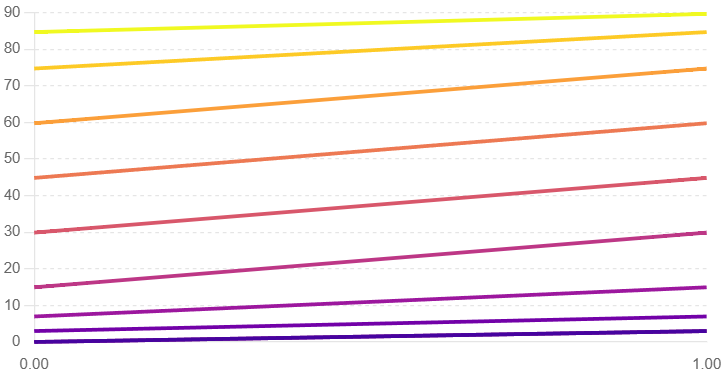

Efficiency vs Flow Rate – Paddle Impeller Performance

At SV Industries, understanding the relationship between efficiency and flow rate is crucial for selecting the right impeller. This section compares paddle impeller performance under varying flow conditions, giving you clear data to support energy-efficient decisions in your mixing process.

Both static charts show how paddle impeller efficiency improves as flow rate increases — giving valuable insight for process optimization. At SV Industries, we use such performance data to design mixers that deliver high output with low energy input, especially for industrial mixing applications.

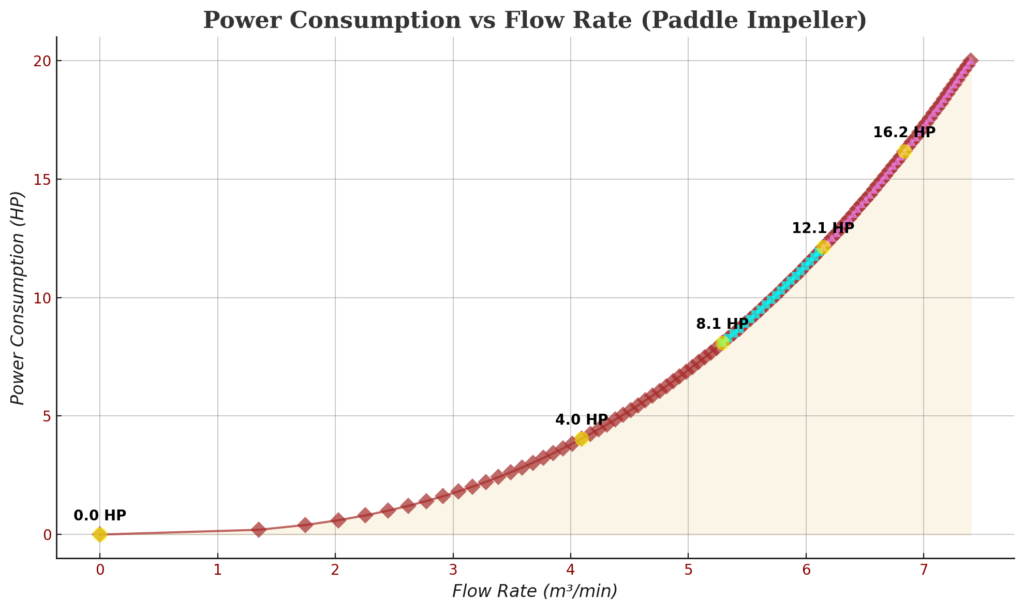

Power Consumption vs Flow Rate – Paddle Impeller Energy Usage

At SV Industries, one of our key priorities is helping industries reduce energy consumption in their mixing processes. This chart shows the relationship between power consumption and flow rate for paddle impellers, making it easier for engineers and operators to plan efficient operations.

As the flow rate increases, power consumption also rises — a natural outcome of resistance and fluid dynamics. At SV Industries, our paddle impellers are engineered to optimize energy use without compromising on performance. This chart can help you plan for power efficiency, especially when dealing with high-volume or high-viscosity applications.

Materials Used in Paddle Impeller Manufacturing

At SV Industries, we prioritize durability, chemical resistance, and performance when selecting materials for our paddle impellers. Based on application needs and industry standards, we manufacture paddle impellers using the following high-grade materials:

Stainless Steel 316 (SS316)

Best Applications for SS316 Paddle Impellers

Corrosive environments and chemical processing.

Key Features:

Exceptional corrosion resistance, especially in chloride-rich and industrial chemical settings. Offers excellent strength even at high temperatures.

Popular Usage:

Pharmaceutical plants, food processing units, petrochemical refineries, and marine industries.

Why Choose SS316?

SS316 paddle impellers are designed to withstand harsh chemicals, acidic solutions, and saline media, making them ideal for industries where hygiene, longevity, and resistance are non-negotiable.

Benefits:

✔️ Long operational life

✔️ Low maintenance in corrosive environments

✔️ High-grade surface finish (easy to clean)

✔️ Compatible with CIP/SIP processes

Stainless Steel 304 (SS304)

Best Applications for SS304 Paddle Impellers

General mixing operations, Food and beverage production, Dairy and cosmetic formulations, Clean water or neutral pH solutions

Key Features:

Good corrosion resistance — Ideal for mildly corrosive or neutral environments

Smooth, polished surface — Easy to clean and maintain hygiene

High mechanical strength — Durable for long-term industrial use

Economical — Cost-effective without compromising on performance

Popular Usage:

Food and beverage industry, Dairy processing, Cosmetic manufacturing, Breweries and distilleries

Why Choose SS304?

If your application doesn’t involve harsh chemicals but requires sanitary processing, SS304 is an excellent choice. It offers the perfect balance of performance, cost, and cleanliness — making it suitable for a wide range of standard mixing operations.

Benefits:

✔️ Food-grade and easy to sanitize

✔️ Budget-friendly with reliable performance

✔️ Widely available and industry-trusted

✔️ Long service life in standard environments

Hastelloy Paddle Impeller

Best Applications for Hastelloy Paddle Impellers

Chemical processing, Pharmaceutical manufacturing, Biotech and biotechnology applications, Marine and offshore environments

Key Features:

Superior chemical resistance — Excellent for aggressive or acidic media. High strength — Offers great durability and structural integrity even at elevated temperatures. Resistant to oxidation — Withstands extreme conditions without degradation. Ideal for challenging environments — Perfect for handling both oxidizing and reducing agents.

Popular Usage:

Chemical Industry: Ideal for mixing and stirring in highly corrosive environments.

Pharmaceutical Manufacturing: Crucial for processes requiring high chemical stability and resistance.

Biotechnology: Used in fermentation and other processes that involve harsh chemicals.

Marine Applications: Suitable for mixing solutions in saltwater and other corrosive marine environments.

Why Choose Hastelloy?

Hastelloy impellers are the go-to choice for industries dealing with extremely harsh chemical processes. Their unmatched resistance to a variety of corrosive agents and their long-lasting durability make them indispensable for reliable performance in critical applications.

Benefits:

✔️ Ultimate corrosion resistance in harsh conditions

✔️ Increased lifespan in aggressive chemical environments

✔️ High performance even under extreme temperatures

✔️ Reliable and low maintenance due to its durable properties

Mild Steel (MS) Paddle Impeller

Best Applications for Mild Steel Paddle Impellers

Paints and coatings, Adhesives and sealants, Water treatment processes, Agricultural mixing, General-purpose industrial mixing

Key Features:

Strong and durable — Mild Steel impellers are robust, offering strength in standard industrial applications. Cost-effective — A budget-friendly option for industries that don’t require high corrosion resistance. Versatile — Suitable for a wide range of general-purpose mixing tasks. Easy to maintain — Lower maintenance costs due to the simplicity of the material.

Popular Usage:

Paints and Coatings: Ideal for mixing paints, varnishes, and other coating materials.

Adhesives & Sealants: Used in the production of adhesives, sealants, and glues where corrosion resistance is not critical.

Water Treatment: Common in water treatment plants for general agitation and mixing tasks.

Agricultural Industries: Used for mixing fertilizers, pesticides, and other non-corrosive substances.

Why Choose Mild Steel?

Mild Steel impellers are an excellent choice for applications where cost-efficiency is as important as functionality. These impellers provide a reliable, cost-effective solution for general-purpose mixing and agitation without compromising on strength and durability.

Benefits:

✔️ Affordable option for standard industrial applications

✔️ Good strength for non-corrosive environments

✔️ Simple to maintain and replace due to material affordability

✔️ Ideal for non-corrosive or mild media

Choosing the right paddle impeller material is crucial for achieving long-lasting performance and operational efficiency in your mixing applications. Different industries demand different levels of corrosion resistance, strength, and cost-effectiveness. That’s why we’ve compared our most popular materials — SS316, SS304, Hastelloy, and Mild Steel — to help you make an informed decision.

| Material | Best For | Key Features | Corrosion Resistance | Common Industries |

|---|---|---|---|---|

| Stainless Steel 316 (SS316) | Corrosive environments, chemical processes | High corrosion resistance, strength at high temperatures | ⭐⭐⭐⭐⭐ | Pharmaceutical, Chemical, Food Processing |

| Stainless Steel 304 (SS304) | General-purpose mixing | Durable, easy to clean, hygienic | ⭐⭐⭐ | Food & Beverage, Dairy, Cosmetics |

| Hastelloy | Highly aggressive or acidic media | Exceptional chemical resistance, high strength | ⭐⭐⭐⭐⭐ | Biotech, Specialty Chemicals, Marine |

| Mild Steel (MS) | Budget-friendly, non-corrosive mixing | Strong, economical, easy maintenance | ⭐ | Paints, Water Treatment, Adhesives |

Still not sure which material is right for your application?

Let’s simplify it:

If your process involves highly corrosive chemicals, go with Hastelloy or SS316.

For general hygienic mixing like in food or dairy, SS304 is a smart and economical choice.

Need a budget-friendly solution for non-corrosive environments? Mild Steel will do the job perfectly.

At SV Industries, we offer full customization based on your process needs — ensuring you get the best balance of durability, performance, and cost-efficiency.

Technical Specifications and Operating Parameters of Paddle Impeller

To optimize any industrial mixing process, understanding the operational parameters of paddle impellers is essential. These parameters—like pressure drop and torque behavior—directly impact energy consumption, motor selection, and overall system efficiency. At SV Industries, we design paddle impellers with careful consideration of these performance metrics to ensure smooth, consistent, and energy-efficient mixing.

In this section, we’ve included key charts that show how our paddle impellers perform under varying conditions of flow rate and rotational speed (RPM). These insights are especially helpful for process engineers, mechanical designers, and plant operators looking to balance performance with durability.

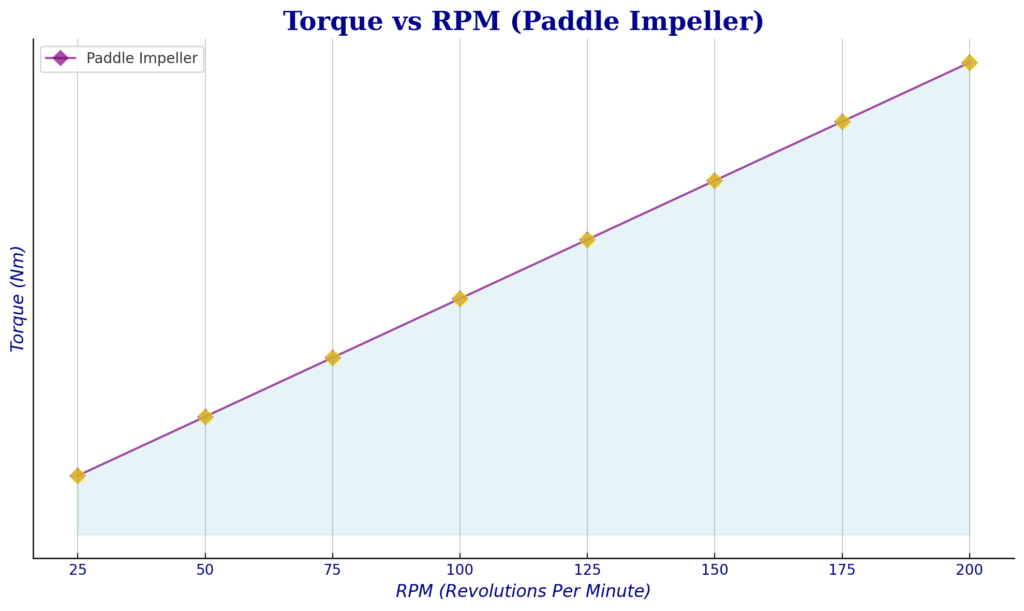

Paddle Impeller Torque vs RPM Chart

Understanding how torque responds to different rotational speeds is essential in mixing system design. The charts below illustrate how the paddle impeller performs as the RPM changes, helping engineers choose the right equipment for viscous and semi-viscous fluids.

Torque is one of the most critical parameters in industrial mixing, especially for processes involving high-viscosity fluids. These charts show how torque requirements vary as the RPM (revolutions per minute) changes, highlighting the importance of selecting the right motor and gearbox configuration.

At SV Industries, we develop paddle impellers that maintain stable torque performance even under demanding conditions, ensuring consistent results and reduced energy loss. These charts are valuable for engineers and plant managers working on high-precision mixing systems.

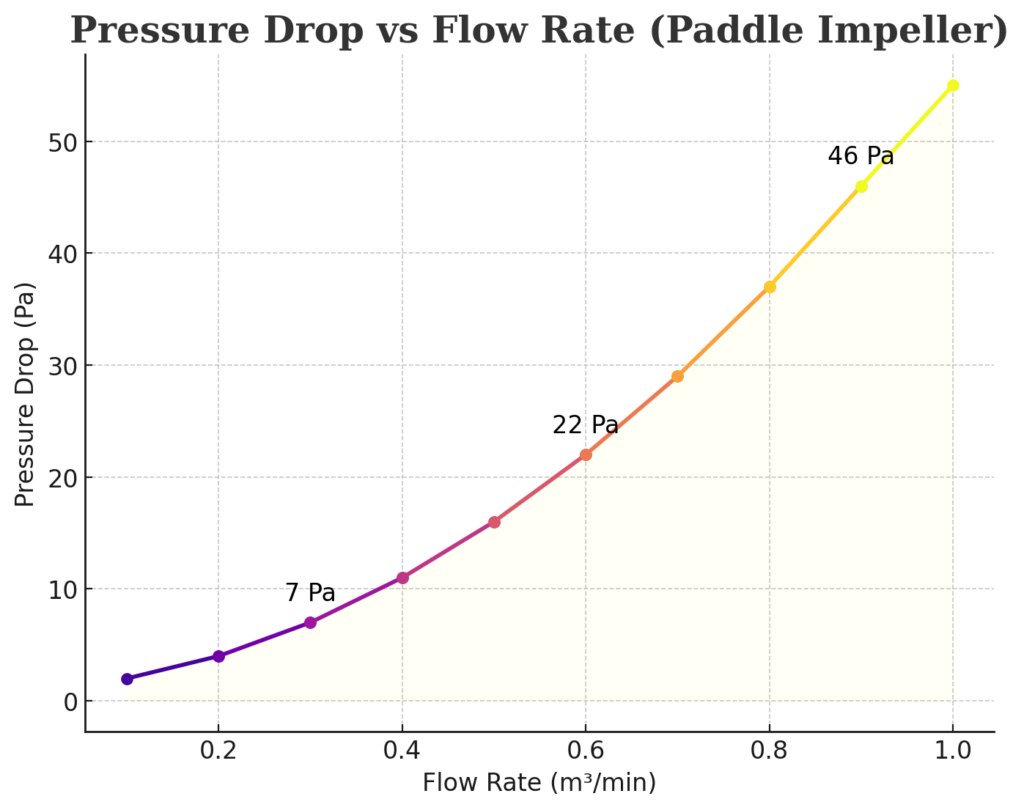

Paddle Impeller Pressure Drop vs Flow Rate Chart

In any mixing system, understanding the pressure drop behavior at varying flow rates is essential for optimizing energy consumption and ensuring smooth operation. The charts below highlight how SV Industries’ paddle impellers perform across different flow rates, helping engineers fine-tune system design.

Pressure drop is a vital metric in fluid dynamics, particularly in industrial mixing applications. As the flow rate increases, resistance inside the tank and pipe system rises, affecting pump selection, energy usage, and throughput.

At SV Industries, our paddle impellers are designed to offer optimized flow paths, reducing unnecessary pressure losses while maintaining effective mixing. These charts assist plant designers in evaluating performance under different operating conditions.

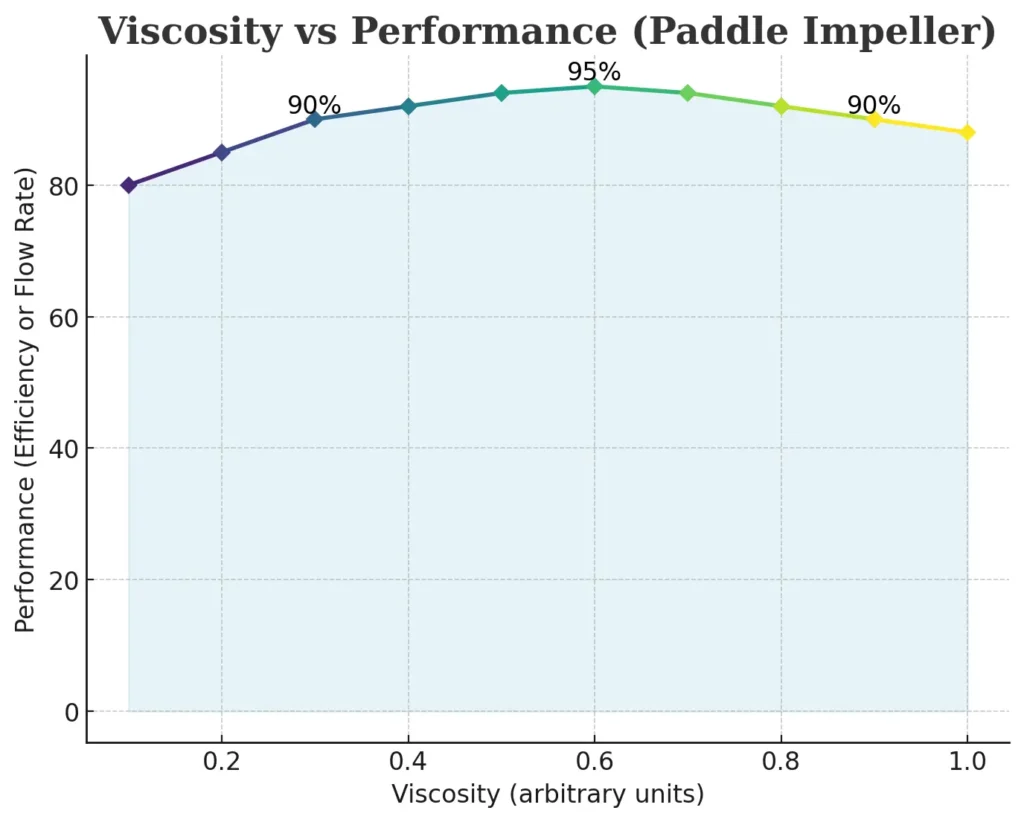

Paddle Impeller Viscosity vs Performance

Fluid viscosity directly impacts the performance of paddle impellers. Thicker (high-viscosity) fluids require more torque and exhibit different flow patterns compared to low-viscosity fluids. This chart, developed by SV Industries, shows how paddle impeller efficiency varies with changing fluid viscosity, helping engineers select the most suitable setup for their process.

Understanding viscosity-dependent performance is essential when choosing paddle impellers for thick fluids like gels or creams. The chart helps identify performance drop zones, suitable operating speeds, and expected mixing times. Trust SV Industries for data-driven recommendations when choosing the right impeller for viscous mixing applications.

Types of Paddle Impellers

At SV Industries, we manufacture a wide range of paddle impellers tailored for different mixing applications. Each type is designed to optimize fluid flow, mixing efficiency, and energy usage. Below are the most commonly used paddle impeller types in industrial processes:

Flat Blade Paddle Impeller

Flat blade impellers are the most standard type. Their simple flat-blade design ensures uniform shear and consistent flow in the tank.

Best For: Low-shear mixing applications

Suitable Fluids: Low-viscosity liquids (e.g., water-based solutions)

Industries: Food & Beverage, Cosmetics, Paints

Advantages: Cost-effective, easy to maintain

Angled Blade Paddle Impeller

These impellers have blades positioned at a slight angle, improving axial flow and turbulence, which results in faster and more thorough mixing.

Best For: Medium-viscosity fluids

Industries: Chemicals, Pharmaceuticals

Advantages: Enhanced fluid circulation, better blending

Perforated Paddle Impeller

Perforated blades contain strategically placed holes that allow fluid to pass through, reducing drag and increasing blending smoothness.

Best For: Heat-sensitive or delicate fluids

Industries: Biotech, Personal Care, Fine Chemicals

Advantages: Gentle mixing, reduced foaming, improved heat exchange

Anchor Paddle Impeller

Designed to scrape the vessel wall during mixing, anchor paddles prevent material buildup and ensure thorough agitation of high-viscosity substances.

Best For: Sticky, thick, or semi-solid materials

Industries: Adhesives, Resins, Food Paste

Advantages: Wall scraping, heat transfer efficiency, consistent mixing

Customized Multi-Blade Paddle Impeller

SV Industries also designs custom paddle impellers tailored to specific process needs. Multi-blade or hybrid impellers combine features of different designs for optimized results.

Best For: Unique mixing challenges

Industries: All major process industries

Advantages: Design flexibility, improved efficiency, process-specific performance

📞 Need a custom solution? Contact us for tailor-made paddle impeller designs.

Understanding Different Types of Paddle Impellers is essential when choosing the right mixing solution for industrial applications. From Flat Blade to Anchor-type and Customized Multi-Blade Paddle Impellers, each design serves a specific purpose—whether it’s handling high-viscosity materials, shear-sensitive fluids, or application-specific mixing requirements. SV Industries offers a complete range of SS316 and SS304 Paddle Impellers, engineered for corrosion resistance, durability, and efficient performance in chemical, pharmaceutical, and food processing industries.

| Type | Blade Design | Ideal for Viscosity | Mixing Pattern | Typical Applications |

|---|---|---|---|---|

| Flat Blade Paddle Impeller | Flat, wide blades at right angles | Medium to high | Radial flow | Chemicals, paints, adhesives |

| Angled Blade Paddle Impeller | Blades set at an angle | Low to medium | Axial + radial flow | Food, pharma, water treatment |

| Perforated Paddle Impeller | Blades with holes/perforations | Medium | Gentle flow with shear | Heat-sensitive liquids, emulsions |

| Anchor Paddle Impeller | Wide blade with side scrapers | High | Wall scraping + radial flow | Viscous pastes, creams |

| Customized Multi-Blade Paddle Impeller | Multiple blades, customized layout | Application-specific | Optimized radial/axial flow | Custom industrial processes, complex mixing |

Applications of SV Industries' Paddle Impeller

SV Industries’ paddle impellers are widely used in industries that require gentle mixing, suspension of solids, and uniform blending. Some common applications include:

Chemical Processing

Paddle impellers are ideal for mixing slurries, suspensions, and high-viscosity fluids, making them essential in industries such as paint production, adhesive manufacturing, and specialty chemicals.

Pharmaceuticals

Paddle impellers are used for mixing creams, gels, suspensions, and other viscous liquids while preventing particle settling and preserving the integrity of active ingredients.

Food and Beverage

Paddle impellers are commonly employed in food manufacturing to mix sauces, dairy products, soups, and other liquids that require gentle blending without shear forces.

Water Treatment

Paddle impellers are used in water treatment plants to agitate chemicals, flocculants, and sludge, helping in the efficient treatment of wastewater.

Cosmetics

In cosmetics, paddle impellers ensure uniform blending of thick creams, lotions, and other personal care products.

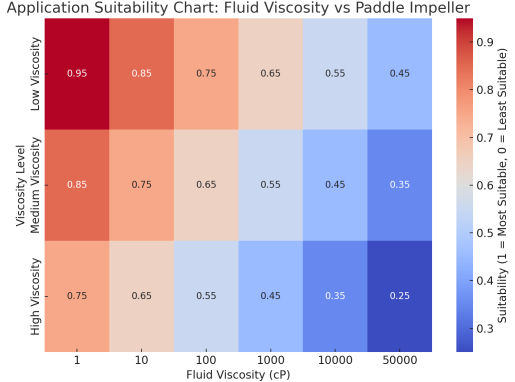

Application Suitability – Fluid Viscosity vs Paddle Impeller Performance

Different fluids behave differently depending on their viscosity, and choosing the right impeller is crucial for consistent and effective mixing. This chart by SV Industries compares the performance of our paddle impellers across various fluid viscosities, helping engineers select the right configuration for their specific application.

This application guide chart clearly maps how paddle impellers from SV Industries perform across fluids with varying viscosities. From thin liquids to thicker mediums, paddle impellers offer reliable mixing where shear is low but volume handling is critical. Use this chart to ensure optimal results for your fluid characteristics and reduce trial-and-error during scale-up.

Paddle Impeller vs Other Mixing Technologies

Choosing the right mixing technology is essential for ensuring process efficiency and product quality. Among the many options available, the paddle impeller stands out for its gentle yet effective mixing capabilities. But how does it compare with other popular choices like anchor, turbine, and propeller impellers? Below is a clear comparison that helps you understand which impeller suits your industrial mixing needs best — especially if you’re working with viscous liquids or chemical-grade formulations.

| Feature | Paddle Impeller | Anchor Impeller | Turbine Impeller | Propeller Impeller |

|---|---|---|---|---|

| Design | Flat blades extending radially from a hub | Anchor-shaped frame hugging tank walls | Multiple flat or curved blades on a disk | 3–4 propeller-style blades, pitched |

| Flow Pattern | Radial and laminar | Tangential and axial (with wall scraping) | Radial or axial (depends on blade angle) | Axial flow |

| Best For | Low to medium viscosity liquids | High viscosity and heat-sensitive fluids | Emulsification, gas dispersion | High flow mixing of low viscosity fluids |

| Viscosity Range | Up to 5,000 cP | Up to 100,000+ cP | Up to 50,000 cP (with baffles) | Below 2,000 cP |

| Energy Efficiency | Moderate energy usage | High due to large surface contact | Moderate to high (based on size) | Highly energy efficient |

| Cleaning & Maintenance | Simple structure, easy to clean | Requires more effort due to size | Moderate complexity | Easy due to compact design |

| Industries Used | Chemicals, pharmaceuticals, food | Cosmetics, adhesives, high-viscosity food | Chemical reactors, fermentation tanks | Water treatment, beverages, paints |

| Heat Transfer Capability | Moderate | High (excellent wall heat exchange) | Moderate | Low |

As you can see, the paddle impeller excels in low-shear mixing, making it ideal for medium to high-viscosity fluids such as chemical slurries, pharmaceutical mixtures, and food-grade pastes. Its simple design, low maintenance, and customization flexibility make it a go-to solution across multiple industries. If you’re still unsure about which impeller to choose, our experts at SV Industries are here to guide you. Let us help you find the perfect industrial stirrer tailored to your process requirements.

Advantages of SV Industries' Paddle Impeller

SV Industries’ paddle impellers offer several advantages that make them the preferred choice for many industries:

Gentle Mixing Action

With their low shear rate, our paddle impellers provide gentle, yet efficient mixing, which is perfect for sensitive applications where maintaining product integrity is crucial.

Energy Efficiency

Our paddle impellers operate at low speeds, reducing energy consumption compared to other high-shear impellers, which makes them a more cost-effective option for continuous use.

Durability

Made from high-quality stainless steel and corrosion-resistant materials, our paddle impellers are built to last, offering long-term reliability and reducing the frequency of maintenance or replacement.

Customizable Design

We offer customized paddle impellers that are tailored to meet specific needs, whether in terms of size, blade angle, or material, ensuring that the impeller fits perfectly with your industrial setup.

Reduced Maintenance

The durable materials and low-speed operation of our paddle impellers result in less wear and tear, leading to fewer breakdowns and lower maintenance costs.

Cost-Effective

The low energy consumption and long service life of our paddle impellers ensure that they are a cost-effective solution for high-volume mixing applications.

Versatility

SV Industries’ paddle impellers can handle a wide range of viscosities, from low-viscosity liquids to more high-viscosity slurries and suspensions, making them ideal for a variety of industries and processes.

Paddle Impeller Performance Analysis

When it comes to industrial mixing, choosing the right impeller depends heavily on performance insights. This section provides a detailed analysis of how the paddle impeller behaves under various operating conditions, helping engineers and plant designers make informed decisions.

At SV Industries, we focus on delivering paddle impellers that are not only durable but also efficient across a wide range of applications. From torque and pressure behavior to flow performance and energy consumption, these performance metrics help showcase the real-world capabilities of our paddle impeller systems.

Explore the charts below to compare essential parameters and understand how the paddle impeller maintains consistent results even in high-viscosity and low-speed mixing environments.

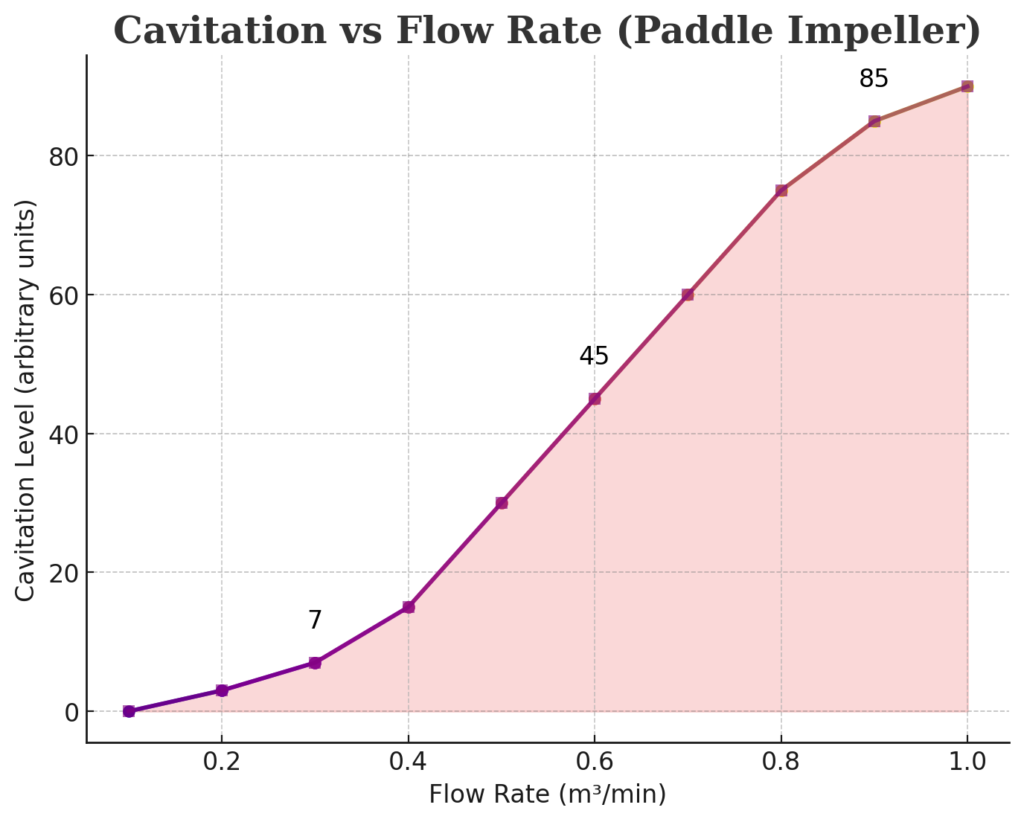

Paddle Impeller Cavitation vs Flow Rate Chart

Cavitation is a critical factor in industrial mixing, especially when operating at higher flow rates. This phenomenon can lead to equipment wear, vibration, and loss of efficiency. The following charts illustrate how SV Industries’ paddle impellers manage cavitation across varying flow conditions, ensuring smooth and reliable performance.

Cavitation typically occurs when the local pressure in the liquid falls below the vapor pressure, forming bubbles that collapse violently. In paddle impellers, controlling cavitation is vital for maintaining long-term performance and reducing maintenance costs.

At SV Industries, our impeller designs are optimized to minimize cavitation risks even under challenging flow conditions. These charts serve as a guide for selecting the right impeller configuration for your specific process requirements.

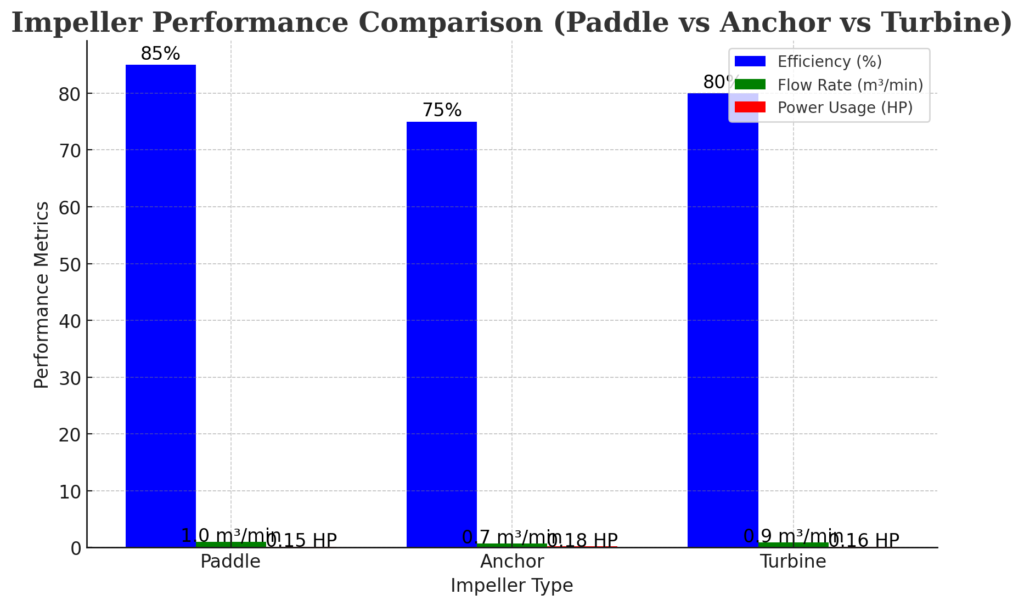

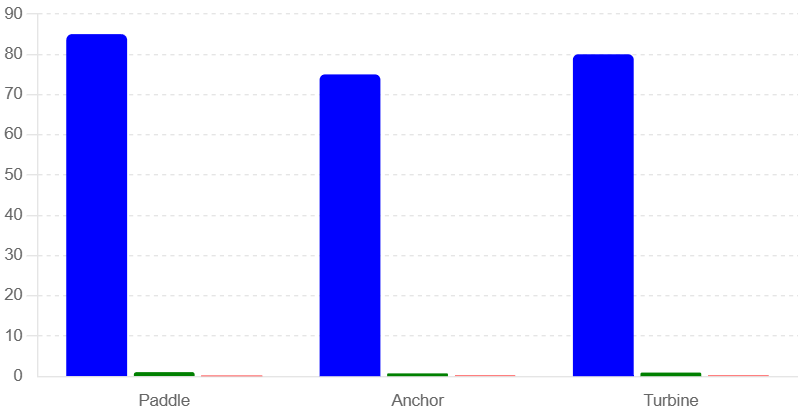

Impeller Performance Comparison: Paddle vs Anchor vs Turbine

Choosing the right impeller is critical for achieving optimal mixing performance. This comparison chart highlights the efficiency, torque, and flow handling capabilities of three major impeller types: Paddle, Anchor, and Turbine. Developed by SV Industries, this data helps engineers make well-informed decisions based on application requirements.

At SV Industries, we understand that different industries require specific impeller designs. While Paddle impellers work best for medium to high viscosity fluids, Anchor impellers suit slow-speed bulk mixing, and Turbine impellers offer high shear mixing in low-viscosity environments.

These charts give you a comparative overview of how each impeller behaves under different parameters like flow rate, energy consumption, and mixing intensity, ensuring you select the best option for your specific process needs.

Key Considerations When Choosing Paddle Impeller Manufacturers and Suppliers

Selecting the right paddle impeller manufacturer and supplier is critical to ensuring the success of your industrial operations. Here are the key factors to consider:

- Experience and Expertise: Opt for manufacturers with a proven track record in designing and producing high-quality paddle impellers. SV Industries, with its extensive experience, is a trusted name in the industry.

- Material Quality: The performance and durability of a paddle impeller largely depend on the quality of materials used. Ensure the manufacturer uses premium-grade materials.

- Customization Options: Industrial requirements vary widely, and a good manufacturer should offer customized solutions to meet specific needs.

- Technological Advancements: Look for manufacturers who leverage the latest technologies and innovations in their designs.

- After-Sales Support: Reliable after-sales support, including installation assistance and maintenance services, is essential for smooth operations.

- Cost-Effectiveness: While affordability is important, it should not come at the expense of quality. Choose manufacturers who offer value for money.

- Client Reviews: Positive reviews and testimonials can provide valuable insights into the reliability and reputation of the manufacturer and supplier.

By considering these factors, businesses can make informed decisions and partner with the best paddle impeller manufacturers and suppliers in India, ensuring efficient and reliable mixing solutions for their operations.

SV Industries: The Trusted Manufacturer and Supplier of Paddle Impellers

SV Industries, based in Ahmedabad, Gujarat, has established itself as a leading manufacturer and supplier of high-quality paddle impellers. Known for our commitment to excellence and customer satisfaction, we have become a trusted name in the industrial sector, delivering efficient and durable paddle impellers to clients across India, including in Gujarat, Rajasthan, Maharashtra, Madhya Pradesh (MP), Uttar Pradesh (UP), and Bihar. With a focus on performance, reliability, and innovation, we provide industrial mixing solutions that meet the unique requirements of a variety of industries.

A paddle impeller is a type of mixing device that is designed to move and mix liquids, typically in low- to medium-viscosity fluids, within a tank or vessel. The impeller features blades that resemble paddles, and it is commonly used in applications that require gentle, yet efficient mixing. Paddle impellers are particularly effective for mixing liquids that do not require high shear forces and are often used in applications such as blending, suspending solids, and creating homogeneous mixtures.

At SV Industries, we understand that the quality and design of a paddle impeller are crucial in achieving optimal mixing results. That is why we manufacture our paddle impellers using the best materials, advanced technology, and a keen focus on precision engineering. Our paddle impellers are designed to provide smooth and efficient mixing, ensuring that your industrial processes are carried out efficiently and with minimal energy consumption.

One of the key reasons for the growing demand for paddle impellers from SV Industries is their ability to handle a wide range of applications. Whether it’s in the chemical industry, pharmaceutical production, food and beverage processing, cosmetic manufacturing, or water treatment, our paddle impellers provide an ideal solution for applications that require low shear forces and gentle mixing. For instance, in pharmaceuticals, paddle impellers are used for suspending solid particles in liquids, preventing any sedimentation while maintaining the product’s consistency. In food and beverage production, paddle impellers help in the gentle mixing of sauces, dairy products, and other low-viscosity materials.

SV Industries’ paddle impellers are designed to operate at moderate speeds, providing efficient and effective mixing while minimizing power consumption. This low-energy requirement makes them a highly cost-effective solution, especially for industries with ongoing high-volume mixing needs. Moreover, the blade configuration ensures that even fluids with suspended particles are thoroughly mixed, preventing settling or clumping, which is critical for consistent product quality. The paddle impeller’s gentle mixing action also helps to preserve the integrity of sensitive materials, making them ideal for use in industries where maintaining the quality of the product is paramount.

In addition to offering high-quality paddle impellers, SV Industries also ensures that each impeller is built to last. We utilize stainless steel, corrosion-resistant alloys, and other high-performance materials to ensure the durability of our paddle impellers. This ensures long-term reliability, reduces the frequency of maintenance, and helps our customers lower their operational costs. The robust design of our paddle impellers allows them to withstand tough industrial environments and handle challenging mixing tasks over extended periods.

One of the major advantages of SV Industries’ paddle impellers is the customization options we offer. We understand that every industrial mixing application is unique, and therefore, we provide tailored paddle impellers to suit the specific needs of our clients. Our team of engineers works closely with clients to understand their mixing requirements, and based on this input, we design and manufacture custom paddle impellers that optimize efficiency, improve output, and reduce energy consumption. Whether it’s a specific size, configuration, or material, we ensure that our impellers match the exact specifications required for your process.

Our paddle impellers are built to ensure reliable performance and superior mixing, making them ideal for industries requiring efficient, energy-saving, and durable solutions. At SV Industries, we are committed to providing products that deliver value, performance, and long-term benefits for our clients.

Frequently Asked Questions (FAQs)

What is a paddle impeller used for?

Paddle impellers are used for gentle mixing, suspending solids, and creating homogeneous mixtures in low- to medium-viscosity fluids.

How does a paddle impeller differ from other types of impellers?

Paddle impellers operate at lower speeds, generating a gentle flow and creating low shear, making them ideal for delicate mixing without damaging sensitive products.

What industries use paddle impellers?

Paddle impellers are used in industries like chemical processing, pharmaceuticals, food and beverage, cosmetics, and water treatment.

Can paddle impellers handle high-viscosity fluids?

Paddle impellers are ideal for low- to medium-viscosity fluids, but they can also handle higher viscosity in certain conditions.

How can I customize my paddle impeller?

SV Industries offers customized paddle impellers with different blade configurations, sizes, and materials to meet your specific mixing requirements.

Are SV Industries' paddle impellers energy efficient?

Yes, our paddle impellers operate at low speeds, consuming less energy than high-shear impellers, which makes them an energy-efficient solution for continuous mixing.

How long do paddle impellers last?

With proper maintenance, SV Industries’ paddle impellers are built to last for years, providing reliable performance with minimal downtime.

What maintenance is required for paddle impellers?

Paddle impellers require minimal maintenance. Regular inspections and cleaning are recommended to ensure optimal performance.

How do I order a paddle impeller from SV Industries?

You can contact our sales team to discuss your specific needs, and we will provide you with a tailored solution based on your requirements.

Why Choose SV Industries for Your Paddle Impeller Needs

SV Industries is your go-to manufacturer and supplier for high-quality paddle impellers designed to meet the needs of various industries. With a commitment to innovation, customer satisfaction, and product reliability, we are confident that our paddle impellers will exceed your expectations and deliver the results you need. Whether you need a standard or custom solution, SV Industries is here to support your business with the best mixing technology available.