Rushton Turbine Manufacturer in India – SV Industries

When you need a reliable, high-performance Rushton Turbine, SV Industries is your trusted partner. As a leading Rushton Turbine manufacturer in India, we combine engineering precision with decades of experience to deliver mixers built for industrial excellence.

Whether you’re in chemical processing, pharmaceuticals, or wastewater treatment, our turbines ensure consistent shear force, gas dispersion, and energy efficiency—making them the preferred choice for high-performance mixing operations.

✅ About SV Industries

Located in Ahmedabad, Gujarat, SV Industries has become a recognized manufacturer of industrial agitators and process equipment. With a growing customer base across India and abroad, we take pride in our:

🔹 4+ years of manufacturing excellence

🔹 Use of premium-grade stainless steel (SS304, SS316, etc.)

🔹 Modern infrastructure and in-house quality control labs

🔹 End-to-end solutions: from custom design to after-sales support

🌍 Service Locations Across India

SV Industries serves clients across major industrial hubs in India, including:

🏭 Ahmedabad, Gujarat – View agitator range

🏭 Vadodara, Maharashtra, Delhi, Tamil Nadu, and more

📦 We offer on-time delivery, site support, and export options

🌐 Ask about our supply capabilities across Asia, Africa & the Middle East

💬 Have a project in mind? Get in touch with us today.

Or message us directly on WhatsApp from our homepage – sv-industries.com

What is a Rushton Turbine?

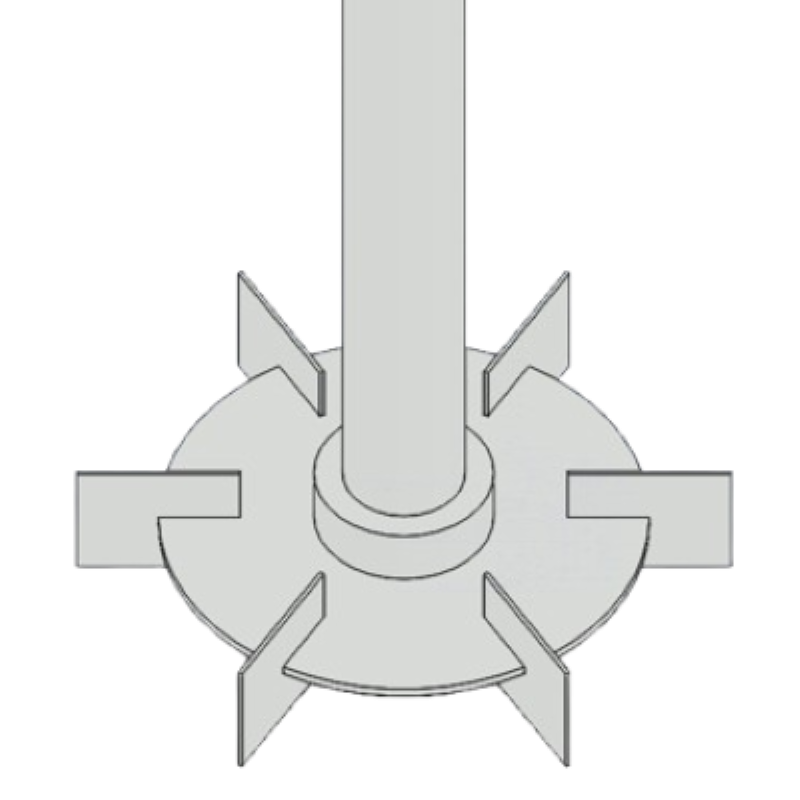

A Rushton Turbine is a type of radial flow impeller used in industrial mixing to deliver high shear and efficient gas dispersion in liquids.

💡 Simple Definition

A Rushton Turbine is a flat-blade impeller designed for high-shear mixing, commonly used in chemical, pharmaceutical, and biotech reactors to disperse gases or blend liquids with precision.

⚙️ How Does It Work?

The turbine consists of a disk with vertical flat blades mounted around it. As the shaft rotates, the blades force the fluid outward in a radial direction, creating zones of turbulence and shear.

This mechanism is highly effective for:

Breaking down gas bubbles

Ensuring uniform mixing of liquids

Enhancing mass transfer in aerated systems

📘 Learn how Rushton Turbines work in industrial reactors: View our Chemical Reactors

🏭 Where Is It Used?

Rushton Turbines are widely used in:

Chemical processing

Bioreactors and fermentation tanks

Wastewater treatment

Paints, inks, and pigment industries

They are the preferred choice for processes that demand gas-liquid mixing, emulsion formation, or suspension of fine solids.

🔍 Need mixing for viscous fluids? Explore Anchor Impeller or Helical Impeller options.

🤝 Need Guidance Choosing the Right Mixer?

Our team at SV Industries can help you select the ideal impeller based on fluid viscosity, tank size, and desired flow pattern.

👉 Contact us now for expert consultation or a custom quote.

How Does a Rushton Turbine Work?

A Rushton Turbine works by using flat vertical blades to generate radial flow and high turbulence, making it ideal for gas-liquid mixing and dispersion operations.

🔄 Step-by-Step Working Principle

The turbine rotates: Powered by a motor, the impeller spins around a vertical shaft.

Blades push fluid outward: The six vertical blades attached to a central disk force liquid to move radially—away from the impeller.

High shear is created: This motion forms intense turbulent zones, breaking down gas bubbles and suspending solids effectively.

Circulation occurs: The fluid hits the tank wall and circulates back through the bottom, ensuring complete mixing throughout the vessel.

🎯 The result? Maximum gas dispersion, uniform composition, and efficient mass transfer—critical in chemical, pharmaceutical, and fermentation processes.

🌊 Flow Behavior of a Rushton Turbine

Generates radial flow: Liquid moves outward from the impeller toward the tank wall.

Forms turbulent eddies: Ideal for breaking up gas bubbles into microbubbles.

Maintains low axial movement, but ensures overall recirculation through tank design.

📊 See performance flow charts in the section below or visit our Agitator page

🧪 Related Products That Work with Rushton Turbines

Anchor Impeller – for slow, viscous blending

Hydrofoil Impeller – for low-shear, high-flow mixing

Chemical Reactors – for optimal agitation vessel design

Design and Engineering of Rushton Turbines at SV Industries

At SV Industries, every Rushton Turbine is a product of precision engineering, tailored to ensure maximum mixing efficiency, durability, and process compatibility.

🔧 Blade Design – Precision Engineered for Performance

Our customized impeller design follows the classic six-blade Rushton configuration, enhanced for:

Optimal radial flow for high shear mixing

Gas dispersion efficiency in aerated systems

Balanced hydrodynamics to reduce vibration and wear

Each blade is CNC-profiled to exact tolerances, ensuring consistent flow behavior and robust performance under varying RPMs.

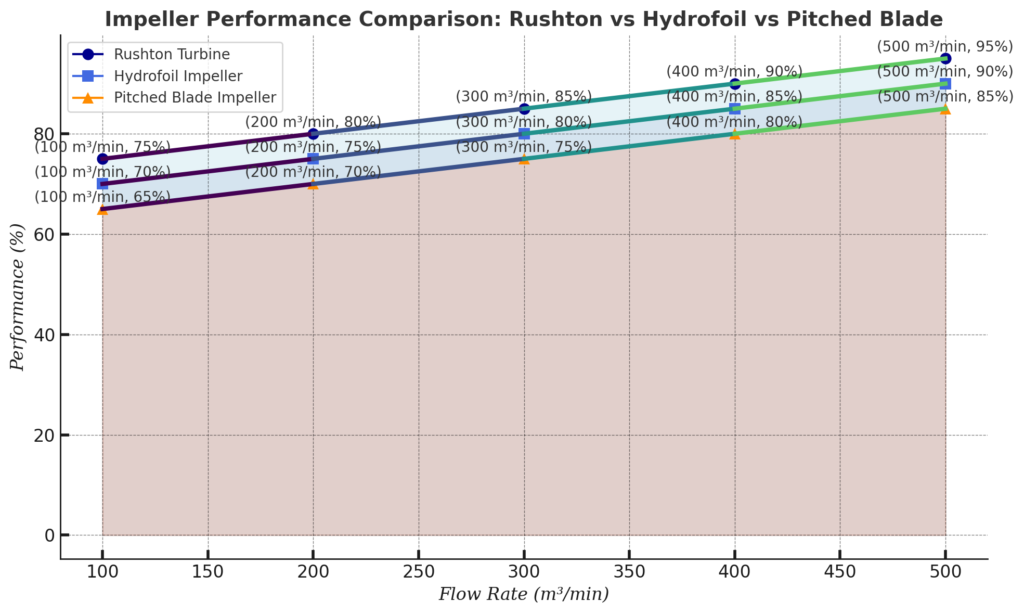

💡 Want to compare impeller types? Check out Impeller Performance Comparison: Rushton vs Hydrofoil vs Pitched Blade

🔩 Weld Quality & Finishing – Crafted for Reliability

All welds are performed with TIG welding technology, ensuring smooth joints and zero contamination.

Internal and external surfaces are buff-polished for cleanability and fluid flow enhancement.

Our weld inspections follow ISO welding quality norms, ensuring leak-proof and durable construction.

🧱 Material Options – Built to Resist and Last

Choose from a wide range of high-grade stainless steels and alloys to suit your process needs:

SS304 – Standard grade, ideal for non-corrosive environments

SS316 / SS316L – Enhanced corrosion resistance, perfect for pharma and chemical sectors

Hastelloy, Titanium, Duplex SS – For highly reactive or acidic environments

Each turbine is selected and built based on your application’s fluid properties, temperature, and chemical compatibility.

📞 Need help with material selection? Talk to our experts today.

✅ Why SV Industries for Rushton Turbines?

Customized impeller design as per your tank geometry

Material traceability and certification provided

Manufactured under strict quality control and ISO standards

Designed to fit any reactor or mixing vessel — including Limpet Coil Reactors and Jacketed Vessels

Technical Specifications of Rushton Turbines

Engineered to meet the rigorous demands of industrial mixing, SV Industries’ Rushton Turbines are crafted with performance, durability, and precision in mind. Below is a detailed breakdown of our standard and custom configuration parameters.

📊 Rushton Turbine Specification Chart

| Parameter | Typical Range |

|---|---|

| Impeller Diameter | 100 mm to 1000 mm (custom sizes on request) |

| No. of Blades | 6 Flat Vertical Blades |

| Tip Speed | 1 – 15 m/s (depending on application) |

| Shaft Speed (RPM) | 50 – 1440 RPM |

| Torque Output | Up to 800 Nm (application-specific) |

| Operating Temperature | Up to 200°C |

| Material Grades | SS304, SS316, SS316L, Hastelloy, Duplex SS |

| Surface Finish | Mirror polish, Buff finish, Electro-polished |

| Mounting Options | Welded or Removable Hub Mount |

| Application Type | Gas dispersion, Emulsification, Fermentation |

🧰 Custom Configurations Available

If your process requires non-standard RPM, custom blade thickness, or special shaft compatibility, our design team will provide a tailored solution based on:

Tank volume and geometry

Fluid viscosity and density

Gas flow rate and dispersion requirement

✅ Our turbines integrate seamlessly with all Agitator assemblies and Reactor Vessels.

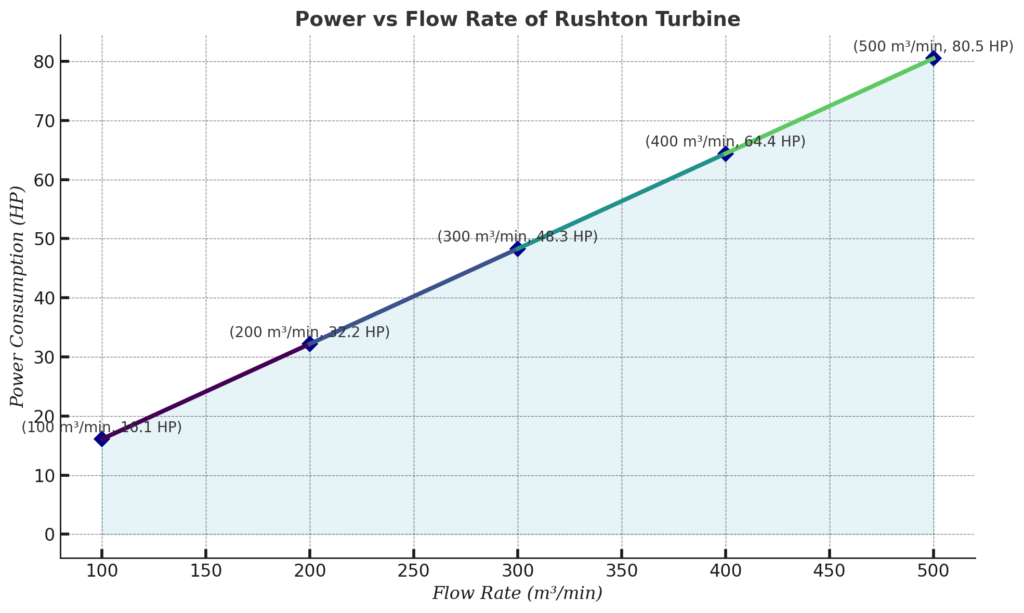

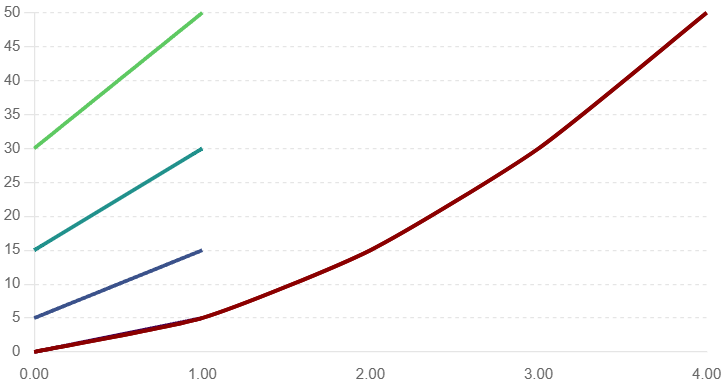

⚡ Rushton Turbine: Power vs Flow Rate Performance Curve

Understanding the relationship between power input and flow rate is crucial for designing an energy-efficient mixing system. The following chart shows how the Rushton Turbine behaves as flow demand increases, helping you predict performance under different operational conditions.

This insight allows plant engineers, process designers, and procurement heads to make informed decisions about scaling, energy cost, and throughput expectations.

📌 What This Chart Tells You

As the flow rate increases, the power consumption of the Rushton Turbine rises non-linearly, typical of high-shear impellers.

The turbine provides excellent mixing performance at lower flow rates with high turbulence, making it highly efficient in applications where mass transfer is a priority.

However, for very high flow rate requirements, power demands increase sharply, which must be factored into system design.

✅ Ideal For

Gas dispersion in fermentation, aeration, or aerobic digestion

High-shear mixing of low to medium viscosity fluids

Processes where aggressive mixing and fast mass transfer are more critical than energy savings

💡 Pro Tip

Looking to optimize energy use? Use Rushton Turbines for batch processes or short-duration mixing cycles where high mixing intensity is needed in less time, thereby saving overall operational energy.

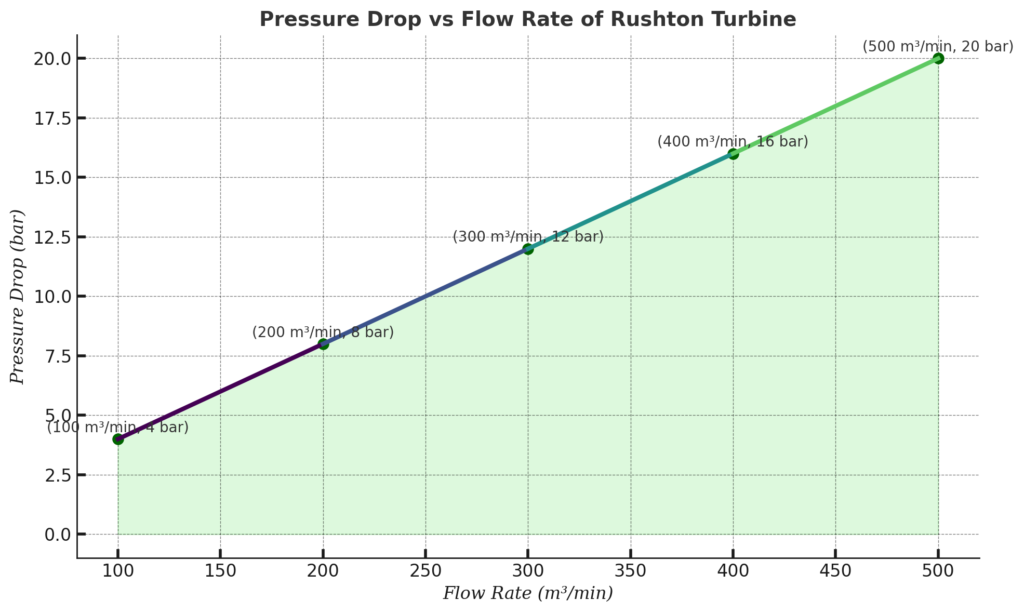

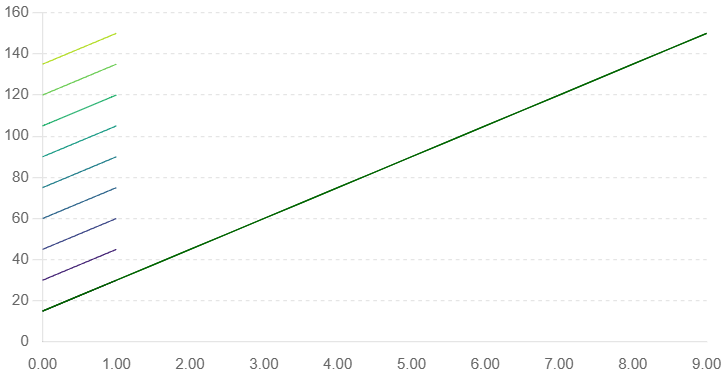

🌀 Pressure Drop vs Flow Rate – Rushton Turbine Performance Insight

Pressure drop is a key performance indicator when evaluating the efficiency and operational cost of a mixing system. The chart below maps how pressure drop varies with flow rate for the Rushton Turbine, enabling better system design and pump selection for engineers and plant operators.

📌 What This Chart Tells You

As the flow rate increases, the pressure drop across the Rushton Turbine also increases—this is typical of radial flow impellers.

At low to moderate flow rates, the pressure drop is manageable, supporting stable and controlled mixing.

At higher flow rates, expect a steeper rise in pressure drop, especially in systems with narrow baffles or viscous fluids.

✅ Why It Matters

High pressure drop leads to higher energy consumption, affecting pump load and system back pressure.

Understanding this curve is essential for optimizing reactor and vessel design, and for choosing compatible pumps and pipelines.

💡 Application Tip

Use Rushton Turbines in systems where gas-liquid dispersion, emulsification, or mass transfer are more critical than minimizing pressure drop. For low-pressure systems, explore Hydrofoil Impellers as an alternative.

Types of Rushton Turbines We Manufacture

At SV Industries, we manufacture a variety of Rushton Turbines tailored to different industrial mixing applications. Each design is crafted for specific flow characteristics, tank sizes, and processing needs — ensuring maximum efficiency and durability in every process.

6-Blade Rushton Turbine

The most widely used and recognized design, this turbine features six vertical flat blades that create intense radial flow and high shear zones. It’s particularly effective for gas-liquid mixing, especially in fermentation and biological processing applications.

Ideal for:

Fermentation tanks

Bioreactors

Wastewater aeration

8-Blade Rushton Turbine

This variant increases the number of blades to eight, resulting in greater turbulence and improved mass transfer efficiency. It’s suitable for high-viscosity fluids or processes requiring stronger shear forces.

Ideal for:

Polymer mixing

Emulsification systems

Dense chemical suspensions

Heavy-Duty Rushton Turbine

Constructed using robust materials like Duplex SS, Hastelloy, or Titanium, this design is built for corrosive and abrasive environments. Reinforced blade structure and superior surface finish ensure reliability in critical operations.

Ideal for:

Mining slurries

Hazardous chemical reactors

Acidic or alkaline media

Customized Rushton Turbine

We understand that no two mixing applications are the same. Our expert team can deliver custom-designed Rushton impellers, including variations in blade angles, diameter-to-tank ratios, and multi-stage assemblies.

Ideal for:

R&D pilot plants

OEM machinery integration

Non-standard tank geometries

🔗 Want help choosing the right turbine? Explore our full Agitator product line or contact our engineers for technical consultation.

Applications of Rushton Turbines Across Industries

Rushton Turbines are renowned for their versatile mixing capabilities and are widely used across multiple industries to optimize processes involving suspension, gas dispersion, and emulsification. Their unique radial flow design makes them ideal for achieving efficient mixing even in challenging conditions like high viscosity fluids or shear-sensitive materials.

| Industry | Used In | Ideal For |

|---|---|---|

| Pharmaceutical | Bioreactors, Vaccine production | Gas dispersion, Cell culture mixing |

| Biotechnology | Fermenters, Growth media preparation | Shear-sensitive agitation |

| Chemical | Reactor vessels, Mixing tanks | Suspension of solids, Gas-liquid reaction |

| Fertilizer | Ammonia reactors, Slurry mixers | Heavy slurry mixing |

| Food & Beverage | Dairy tanks, Syrup blenders | Homogenization, Emulsion |

| Water Treatment | Aeration tanks, Clarifier mixers | Oxygen dispersion, Sludge agitation |

| Petrochemical | Crude oil mixers, Additive blending | High-temperature mixing |

| Pulp & Paper | Bleach mixing tanks, Fiber suspension | Fiber dispersion, Bulk mixing |

| Paint & Coatings | Pigment mixers, Binder tanks | Shear mixing, Viscous blending |

| Cosmetics | Cream & lotion blenders | Emulsification, Homogeneous mixing |

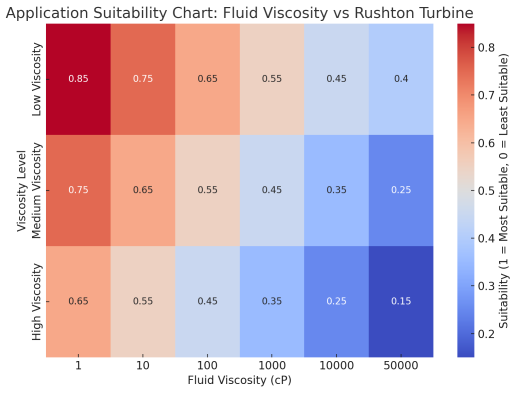

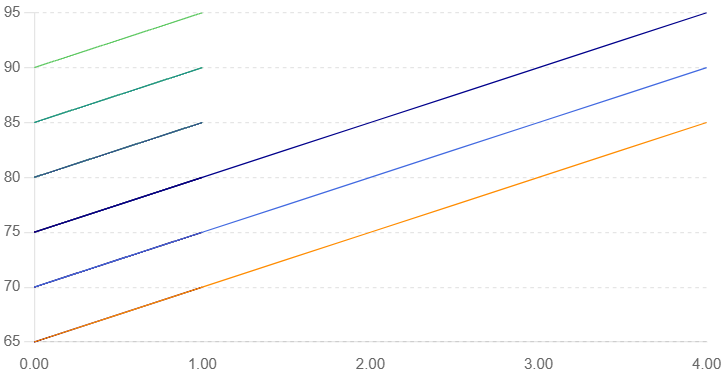

📊 Application Suitability Chart – Fluid Viscosity vs Rushton Turbine

Understanding fluid viscosity is essential for selecting the right impeller in any mixing system. Rushton Turbines, known for their high-shear mixing capabilities, are best suited for applications where gas dispersion, emulsification, or solid suspension in low to medium-viscosity fluids is critical.

This chart visually demonstrates how fluid viscosity influences the mixing efficiency and application suitability of Rushton Turbines.

📌 What This Chart Tells You

✔ Low-viscosity fluids like water, alcohols, or dilute chemicals are ideal for Rushton Turbines due to their radial flow and intense vortex formation, which promote excellent gas-liquid dispersion.

✔ Medium-viscosity fluids such as polymer solutions, nutrient broths, or mild emulsions can be effectively agitated using a customized blade diameter-to-tank ratio or increased blade count for enhanced turbulence.

✖ High-viscosity fluids—such as pastes, gels, creams, or dense slurries—are not typically ideal for Rushton Turbines unless assisted by additional impellers like the Anchor Impeller or used in combination systems.

🧪 Mixing Expertise That Matches Your Material

At SV Industries, we evaluate the rheological properties of your fluid and engineer the Rushton Turbine design accordingly—optimizing blade pitch, number, and RPM for your process.

For fluids beyond Rushton’s optimal range, we also offer:

Hydrofoil Impellers – for low-viscosity, energy-efficient mixing

Paddle Impellers – suited for laminar and transitional flow

Pitch Blade Turbines – effective across viscosity gradients

Advantages and Performance Benefits of Rushton Turbines

In demanding industrial environments, performance and durability are non-negotiable. That’s why engineers across chemical, pharmaceutical, and wastewater industries choose SV Industries’ Rushton Turbines — precision-crafted for high-shear mixing, gas dispersion, and reliable long-term use.

🔍 Key Advantages at a Glance

🔩 High Shear Mixing:

Radial flow and sharp-edged flat blades create intense turbulence, perfect for dispersing gases or solids.

🛡️ Robust Construction:

Crafted from SS316, SS304, and custom alloys for exceptional corrosion and wear resistance.

⚙️ Low Maintenance Design:

Fewer moving parts mean lower maintenance, less downtime, and higher productivity.

🧪 Process Versatility:

Works seamlessly across a variety of tank sizes and operating conditions.

🔧 Custom-Built for Industry Needs:

From small-scale R&D to large-scale production, each turbine is tailored for maximum compatibility and performance.

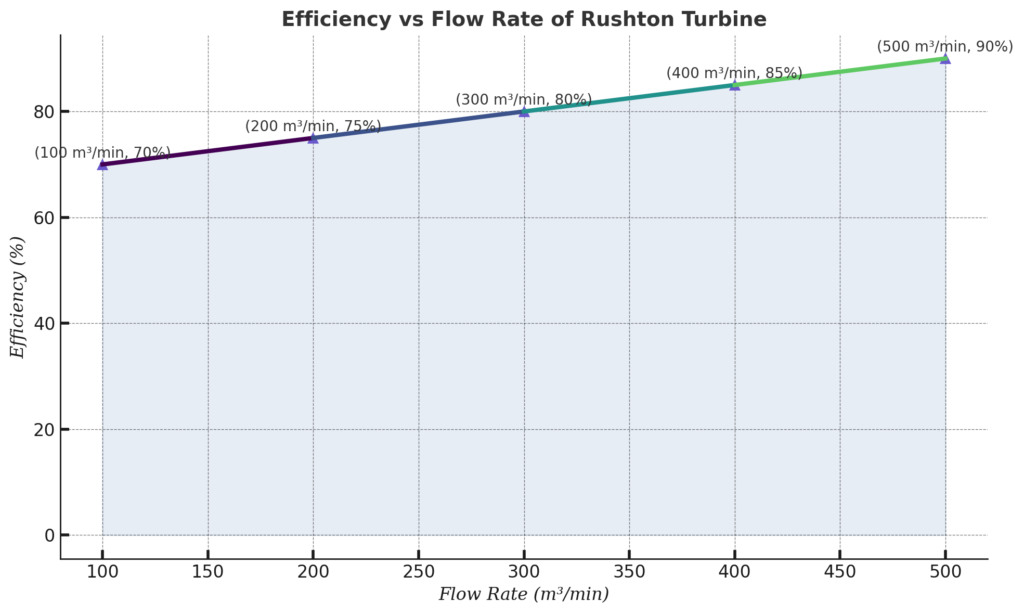

⚙️ Efficiency vs Flow Rate – Rushton Turbine Performance Curve

When selecting an industrial impeller, mixing efficiency plays a vital role in minimizing energy consumption while achieving process goals. This chart illustrates how the Rushton Turbine’s efficiency changes with varying flow rates, providing valuable insight for process engineers, plant heads, and procurement teams.

📌 What This Chart Tells You

The Rushton Turbine exhibits high mixing efficiency at low to moderate flow rates, especially in applications requiring gas dispersion or mass transfer.

As flow rate increases beyond optimal levels, efficiency starts to decline, due to greater turbulence and energy losses from vortex formation.

For operations targeting shear-intensive mixing, this performance is ideal—but if energy savings at high flow is a priority, alternative impellers may be better suited.

✅ Best Use Cases

Fermentation and aeration in biopharma and wastewater treatment

Exothermic reactions in chemical reactors

Gas-liquid mixing where mass transfer rates are critical

💡 Expert Tip

Efficiency can vary with fluid viscosity and vessel geometry. Pairing a Rushton Turbine with a correctly sized Reactor Vessel or Chemical Process Reactor will maximize output and energy performance.

📞 Need to Maximize Efficiency in Your Mixing System?

Let our design engineers suggest the ideal setup.

👉 Request a Free Consultation

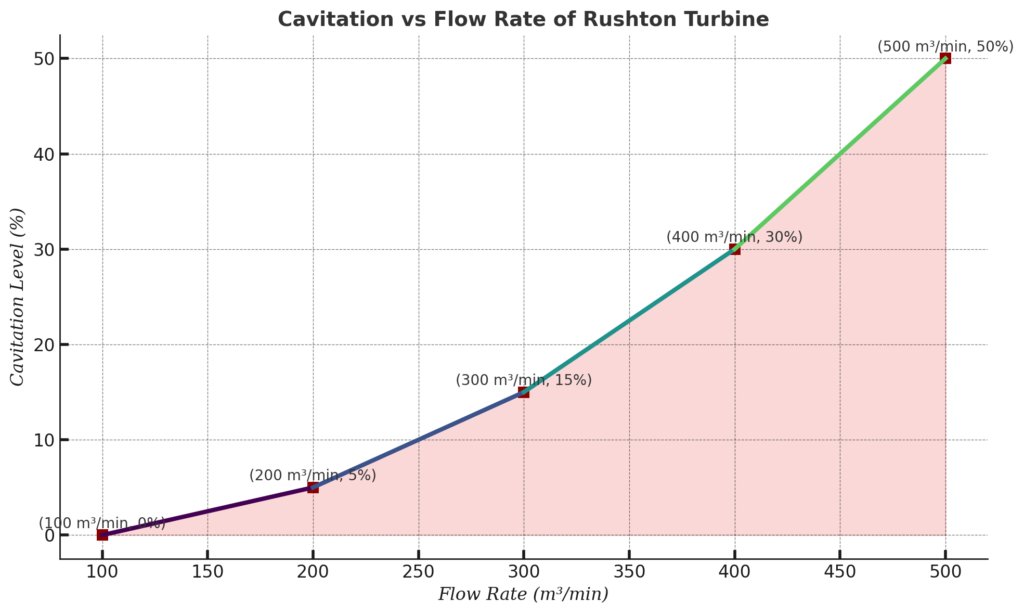

💥 Cavitation vs Flow Rate – Rushton Turbine Performance Analysis

Cavitation is a critical concern in high-speed mixing systems—it can cause impeller damage, reduce mixing efficiency, and shorten equipment life. The following chart illustrates the relationship between flow rate and the likelihood of cavitation in a Rushton Turbine, helping engineers make better design and operational decisions.

📌 What This Chart Tells You

At low to moderate flow rates, cavitation risk is minimal, and the Rushton Turbine delivers stable and consistent mixing.

As flow rate increases, especially in systems with gas entrainment, the risk of cavitation rises sharply.

The threshold beyond which cavitation becomes a concern depends on fluid properties, pressure conditions, and impeller speed.

✅ Design & Operation Insights

Ideal for applications requiring high shear and gas dispersion, such as aerobic fermentation or chemical oxidation.

For high flow rate systems, anti-cavitation design features and precise RPM control should be implemented.

Cavitation damage can be reduced through correct vessel design and impeller placement—our Chemical Process Reactors are built with this in mind.

💡 When to Choose Rushton Despite Cavitation Risk

Even with cavitation risks at higher speeds, Rushton Turbines are often preferred for their superior mass transfer, gas-liquid mixing, and shear delivery, especially in batch reactors and bioreactors.

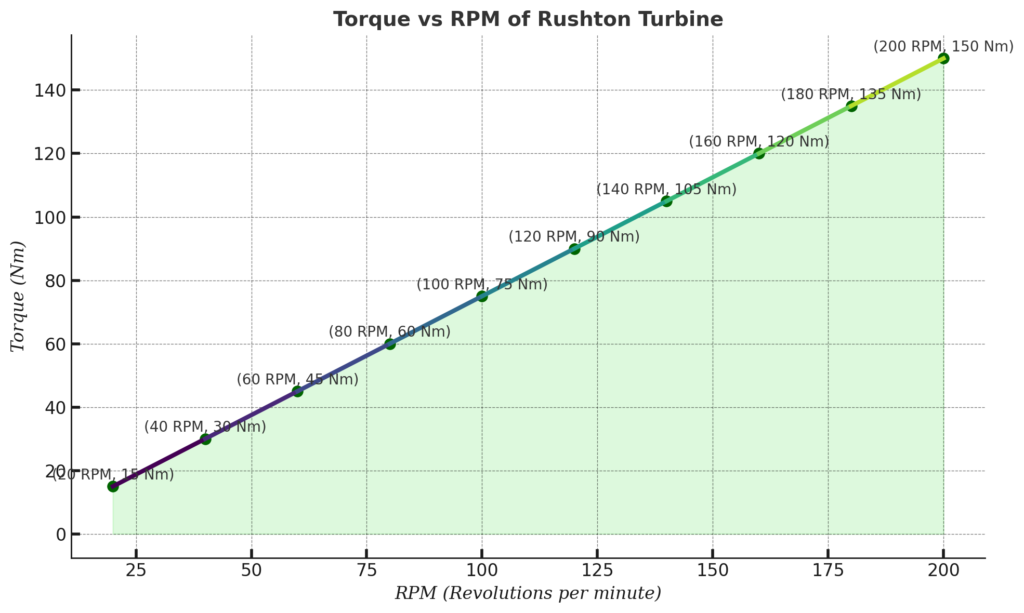

🔄 Torque vs RPM – Understanding Rushton Turbine Load Behavior

Torque is a direct indicator of the mechanical load experienced by your mixing system. The Rushton Turbine, known for its high-shear mixing capabilities, exhibits a specific torque behavior as RPM (Revolutions Per Minute) changes. This chart helps engineers, plant managers, and equipment designers understand how to optimize motor selection and operational efficiency.

📌 What This Chart Tells You

At lower RPMs, torque remains moderate, ideal for gentle mixing or start-up phases.

As RPM increases, torque rises exponentially, reflecting the impeller’s intense radial flow and gas dispersion workload.

This pattern demands robust motor systems and well-calibrated speed control, especially in viscous or gas-laden fluids.

✅ Design Considerations for Torque Management

Use variable frequency drives (VFDs) to manage torque surges.

Ensure compatibility with Reactor Vessels and Chemical Reactors that can withstand high dynamic loads.

Proper bearing alignment and shaft support can prolong system life under high torque.

💡 Why Torque Monitoring Matters

Consistent torque monitoring prevents motor overload, enhances energy efficiency, and enables predictive maintenance, reducing unplanned downtime.

Rushton vs Other Impeller Types – Comparative Performance

Choosing the right impeller is critical to the efficiency, cost-effectiveness, and consistency of your mixing process. At SV Industries, we help customers make the right choice by offering clear insights and side-by-side performance comparisons.

To help you decide when a Rushton Turbine is your best choice, here’s how it stacks up against two other popular designs: Hydrofoil Impellers and Pitched Blade Turbines (PBT).

📊 Impeller Performance Comparison

| Feature / Type | Rushton Turbine | Hydrofoil Impeller | Pitch Blade Turbine (PBT) |

|---|---|---|---|

| Flow Pattern | Radial | Axial | Axial + Radial |

| Shear Intensity | High (ideal for gas dispersion, emulsions) | Low to Moderate (ideal for blending, heat transfer) | Moderate (good for solids suspension) |

| Power Consumption | Higher | Low-energy design | Moderate |

| Gas Dispersion | Excellent | Limited | Moderate |

| Viscosity Handling | Low to Medium | Medium | Medium to High |

| Best Use Case | Gas-liquid reactions, fermentation, emulsification | Energy-efficient blending, heat transfer, bio-processing | Solids suspension, mixing of medium-viscosity fluids |

🔍 When to Choose a Rushton Turbine Over Others

✅ When high shear and strong radial flow are essential

✅ When efficient gas dispersion is the key requirement

✅ When you’re dealing with low- to medium-viscosity fluids

✅ When aggressive mixing or solid-gas dispersion is needed

✅ When process control depends on uniform turbulence

💡 SV Industries — Helping You Make the Right Choice

At SV Industries, we don’t just manufacture impellers — we engineer solutions. If your process needs controlled shear, tight mixing zones, or high oxygen transfer rates, the Rushton Turbine is likely your best bet.

Need a custom impeller solution? Explore more:

🔗 Hydrofoil Impeller – for energy-efficient low-shear processes

🔗 Pitched Blade Turbine (PBT) – for multipurpose mixing

🔗 Anchor Impeller – best for high-viscosity materials

🔗 Agitators – full range for all mixing applications

📊 Impeller Performance Comparison: Rushton vs Hydrofoil vs Pitched Blade

When selecting the right impeller for your mixing system, understanding how each type performs across key parameters is critical. This comparative chart gives you a clear snapshot of how Rushton Turbines, Hydrofoil Impellers, and Pitch Blade Turbines (PBTs) perform in various industrial mixing conditions.

This side-by-side breakdown helps you choose the most efficient impeller based on your fluid properties, mixing objectives, and energy consumption goals.

🧠 When to Choose What?

Choose Rushton Turbine when your priority is gas dispersion, emulsification, or solid-liquid mixing in low-viscosity fluids.

Choose Hydrofoil Impeller for low power input, bulk liquid movement, and heat transfer efficiency — ideal for biotech, water treatment, and food applications.

Choose Pitched Blade Turbine when you need versatility, especially in moderate to high-viscosity fluids, or require balanced flow patterns for complex blending.

💡 Expert Tip

If your mixing needs span different viscosities or involve both dispersion and blending, a hybrid impeller system combining Rushton and Hydrofoil or PBT might be ideal.

🎯 Still Unsure?

Let our engineering team help you select the perfect impeller combination for your industrial process.

👉 Talk to an Expert Now

What to Consider When Selecting a Rushton Turbine Manufacturer or Supplier

Choosing the right Rushton Turbine manufacturer is a critical decision that impacts not just your equipment cost, but also process performance, maintenance downtime, and product quality. Whether you’re scaling up a chemical plant or optimizing an existing reactor, here’s what to evaluate:

🧱 ✅ Build Quality

When evaluating a supplier, ask:

✔️ Does the manufacturer use industrial-grade materials like SS316, SS304, or Hastelloy for corrosion resistance and durability?

✔️ Are the impellers CNC-machined or cast with precise tolerances?

✔️ Is the turbine designed to suit my tank dimensions and process requirements?

✔️ Can they provide custom solutions for baffles, blade diameter, and hub design?

At SV Industries, we ensure:

Precision-built impellers using certified stainless steel

Welding and fabrication as per ASME guidelines

Designs tailored to maximize mixing efficiency and minimize energy loss

Compliance with GMP, ISO, and custom chemical mixing standards

🧪 ✅ Testing & Validation

Ask your supplier:

✔️ Do they conduct dynamic balancing and stress testing?

✔️ Can they provide flow simulation or CFD analysis reports?

✔️ Is the product validated for chemical, pharmaceutical, or food-grade usage?

SV Industries provides:

Pre-dispatch dynamic balancing reports

Support for CFD testing and performance validation

Material Traceability Reports (MTC), QA test certificates, and custom documentation

🛠️ ✅ After-sales Support

Before finalizing, consider:

✔️ Is there technical documentation and installation support provided?

✔️ Do they offer maintenance guidelines or on-site service?

✔️ Is customer support responsive and knowledgeable about your application?

With SV Industries, you get:

Dedicated engineering support team for commissioning and troubleshooting

Prompt help via Contact Us or email

Fast replacement of parts and custom spares availability

Lifetime support for clients under AMC or warranty plans

What Do Rushton Turbine Manufacturers Do?

If you’re wondering, “What exactly does a Rushton Turbine manufacturer do?”, you’re not alone. Whether you’re a plant engineer, project consultant, or someone exploring industrial mixing solutions, this simple breakdown will help you understand the process—from idea to installation.

🧠 1. Design Engineering

A good Rushton Turbine manufacturer starts by understanding your process requirements:

What fluid are you mixing?

What’s the viscosity, tank size, and RPM needed?

Is the process aerobic or anaerobic, high shear or gentle blending?

Using this data, engineers create a custom impeller design tailored for maximum mixing efficiency, high mass transfer, and reduced power consumption.

At SV Industries, our in-house design team uses 3D CAD modeling and CFD simulation tools to optimize every blade and hub before fabrication.

🏗️ 2. Fabrication & Material Selection

Once the design is approved, the next step is precision fabrication:

Cutting and shaping high-grade stainless steel (SS316/SS304)

Assembling blades and hubs using TIG/MIG welding

Ensuring perfect balance for smooth, vibration-free operation

Every component is built to match GMP, ASME, and industry-specific norms. Our fabrication facility also supports custom alloy construction like Hastelloy or Inconel.

🧪 3. Testing & Quality Checks

Before dispatch, your Rushton turbine undergoes:

Dynamic balancing to eliminate operational vibration

Dimensional accuracy checks to match CAD specs

Material testing reports (MTC), hardness testing, and optional flow simulations

Surface finish checks—especially for pharma or food-grade applications

This ensures every unit performs reliably in high-demand industrial environments.

🚚 4. Packaging, Delivery & Support

The final step: secure packaging and timely dispatch. Manufacturers also provide:

Installation manuals, CAD drawings, and performance certificates

After-sales support including on-site guidance, virtual troubleshooting, and AMC plans

Spare parts availability and assistance for future upgrades

SV Industries ships turbines across India and globally, ensuring quality remains intact from our shop floor to your plant.

Why Choose SV Industries for Rushton Turbines?

When you’re investing in a Rushton Turbine, you’re not just buying an impeller—you’re choosing a technology partner. At SV Industries, we combine engineering precision, global standards, and customer-first values to deliver results you can trust.

💡 Here's Why Industrial Buyers Prefer SV Industries:

🔧 Decades of Manufacturing Expertise

With over 4 years of hands-on experience, we’ve supplied high-shear mixing solutions to chemical, pharmaceutical, food, and wastewater plants across India and abroad.

We understand the real-world challenges of industrial mixing, and we design turbines that perform under pressure.

💰 Competitive Pricing Without Compromise

We offer factory-direct pricing—no middlemen.

Thanks to our in-house design, fabrication, and testing setup, you get premium-quality Rushton Turbines at a cost that fits your budget.

🌍 3Domestic & Export Capability

SV Industries proudly serves clients not just in Gujarat and Pan India, but also in international markets.

We meet export packaging standards, provide custom documentation, and support OEM projects globally.

🧪 Precision Built. Tested for Excellence.

Our turbines go through CFD-backed design, dynamic balancing, and stringent quality checks.

Whether it’s for aeration, gas dispersion, or batch mixing, you can rely on smooth operation, zero vibration, and long service life.

📞 Responsive After-Sales Support

We’re known for our quick response, custom spares, and engineer consultation even after delivery.

We believe in partnership, not just supply.

Frequently Asked Questions (FAQs) About Rushton Turbines

What is a Rushton Turbine?

A Rushton Turbine is a radial-flow turbine designed with flat blades at a 45-degree angle, widely used for gas-liquid mixing and solid suspension in a variety of industries.

How does a Rushton Turbine work?

The Rushton Turbine creates high shear and radial flow within a mixing vessel, efficiently dispersing gases and suspending solids in liquids. Its high-speed operation makes it ideal for aeration and high-viscosity fluid mixing.

What industries use Rushton Turbines?

Rushton Turbines are used in industries like chemical processing, pharmaceutical manufacturing, biotechnology, food and beverage production, and wastewater treatment.

What is the difference between a Rushton Turbine and other turbines?

The main difference is the 45-degree blade angle and high shear capacity, which make the Rushton Turbine ideal for gas-liquid dispersion and solid suspension.

What materials are used to make Rushton Turbines?

SV Industries uses stainless steel and alloy steels to manufacture Rushton Turbines, ensuring durability and resistance to corrosion in harsh environments.

Can Rushton Turbines handle high-viscosity fluids?

Yes, Rushton Turbines are suitable for mixing high-viscosity fluids, especially when used at high speeds.

How do I choose the right Rushton Turbine for my application?

Choosing the right turbine depends on factors like fluid properties, shear requirements, and mixing goals. SV Industries offers customized Rushton Turbines tailored to your specific needs.

What is the role of a Rushton Turbine in fermentation?

In fermentation, Rushton Turbines are used to efficiently mix liquid media, ensuring proper gas-liquid dispersion and adequate oxygen transfer to microorganisms.

How do I maintain a Rushton Turbine?

Regular cleaning, lubrication, and inspection for signs of wear or damage are essential for maintaining a Rushton Turbine.

Where does SV Industries supply Rushton Turbines?

SV Industries supplies Rushton Turbines to regions including Gujarat, Rajasthan, Maharashtra, Madhya Pradesh, Uttar Pradesh, and Bihar.