Helical Impeller Manufacturer in India | SV Industries

Looking for a Helical Impeller Manufacturer in India? At SV Industries, we bring over a decade of experience in delivering custom-designed helical impellers that offer superior performance in demanding industrial mixing environments. Our impellers are specifically built to handle high-viscosity fluids, non-Newtonian substances, and sensitive formulations that require gentle yet efficient axial flow.

Whether you’re mixing polymers, emulsions, resins, or pharmaceutical compounds, our high-efficiency helical impellers provide uniform blending, faster batch processing, and reduced energy consumption — even in jacketed reactors, process vessels, and storage tanks. Each impeller is fabricated using premium stainless steel and designed for optimal shear distribution, torque balance, and thermal transfer.

We don’t just offer impellers; we provide process-engineered solutions customized to your fluid dynamics, vessel size, and industry standards.

✔️ Custom-built solutions for viscous and complex fluid mixing across pharmaceutical, chemical, cosmetic, and food industries

What is a Helical Impeller?

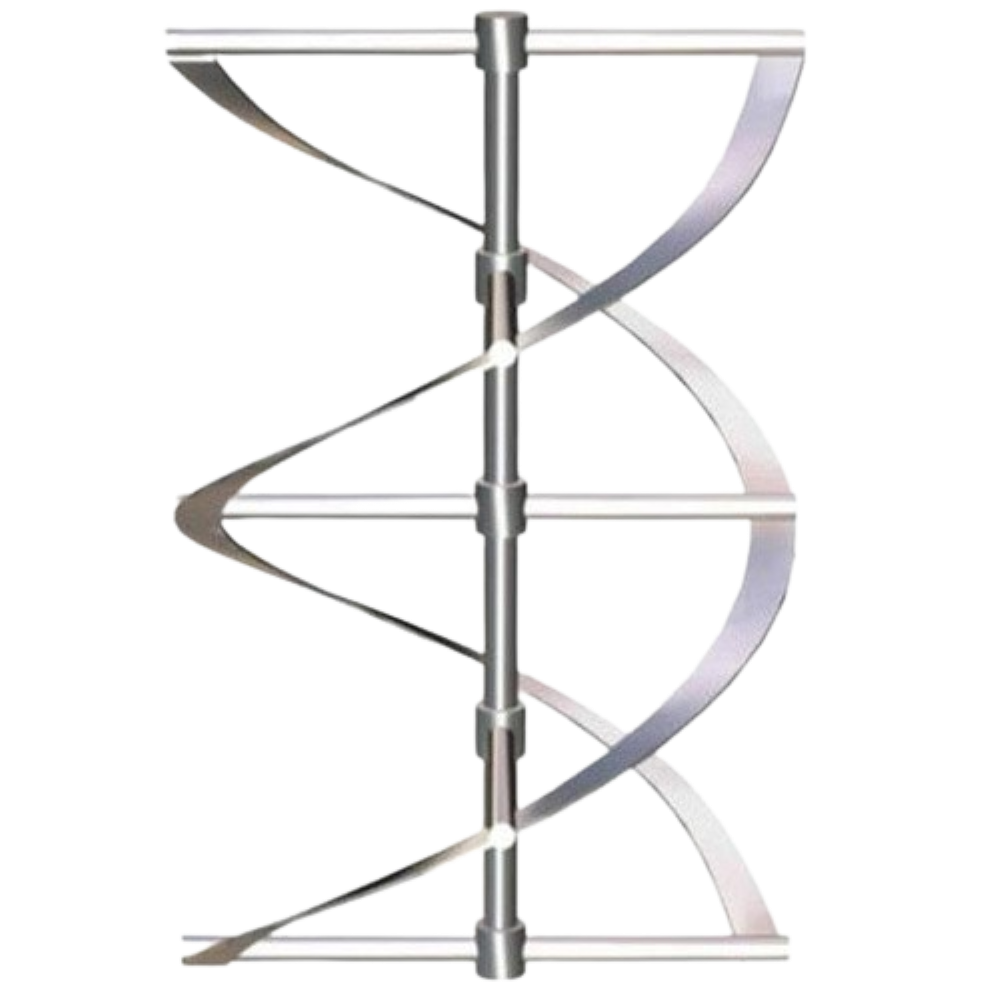

A Helical Impeller is a type of industrial mixing blade designed specifically for efficient mixing of high-viscosity fluids, semi-solid materials, and non-Newtonian liquids. It features a helix-shaped blade that wraps around a central shaft, enabling strong axial flow from top to bottom within a mixing vessel.

This unique design allows it to continuously move dense or sticky materials, preventing sedimentation and ensuring uniform mixing — even in large jacketed reactors, chemical vessels, and storage tanks. Because of its ability to handle difficult materials without damaging product integrity.

✅ Typically used in:

Pharmaceutical manufacturing

Adhesive and resin processing

Food and cosmetic blending

Chemical reactors

⚙️ Key Features & Characteristics

Promotes axial circulation for thorough batch homogenization

Ideal for scraping vessel walls, reducing dead zones

Minimizes shear stress, preserving delicate compounds

Performs exceptionally in high-viscosity and low-speed operations

💡 Used in mixing viscous fluids like adhesives, gels, creams, and polymers, Helical Impellers are essential in industries requiring precision and consistency.

How Does a Helical Impeller Work?

A Helical Impeller works by creating a continuous axial flow through a spiral-shaped blade that wraps around the shaft like a screw or ribbon. As the impeller rotates, it gently lifts the fluid upward along the vessel wall and then pushes it downward through the center — enabling a top-to-bottom circulation known as axial flow.

Unlike radial flow impellers (which push fluid outward from the center), the helical impeller promotes axial movement, ensuring that even high-viscosity fluids like gels, pastes, or polymer mixtures are thoroughly and evenly mixed — without dead zones or sedimentation.

🌀 Working Principle:

The helix blade generates a screw-like motion that moves material along the vessel wall.

This creates a circular axial flow pattern ideal for blending dense or slow-moving fluids.

The impeller operates at low to medium RPM, minimizing shear stress and protecting fragile compounds.

⚙️ Fluid Dynamics at a Glance:

Axial Flow

Moves fluid vertically through the vessel, top to bottom.

Radial Flow

Moves fluid horizontally outward from the shaft — less effective for viscous materials.

Shear Behavior

Designed to create low to moderate shear, preventing breakdown of sensitive components.

💡 Helical impellers are often used in jacketed vessels where both heat transfer and fluid circulation must happen simultaneously — making them ideal for reactors, viscous mixers, and cooling tanks.

Design Features of SV Industries’ Helical Impeller

At SV Industries, our Helical Impellers are crafted with precision to deliver efficient, low-shear mixing performance across demanding industrial applications. Every component is engineered with a strong focus on durability, customizability, and compliance with CIP (Clean-in-Place) standards.

🔧 Precision Impeller Geometry

Helix Angle & Blade Pitch

Optimized for maximum axial flow and effective wall-to-center circulation, ensuring even mixing of high-viscosity fluids.

Shaft Compatibility

Designed for integration with a wide range of agitator shafts, including top-entry and bottom-entry configurations.

Blade Width and Thickness

Tailored to the rheology of the fluid — from light gels to heavy resins.

✨ Surface Finishing & Sanitary Design

Mirror-polished and electropolished finishes available for pharma-grade and food-grade mixing systems

Fully CIP-compatible to reduce contamination risk and cleaning downtime

Optional PTFE coating for corrosive or sticky substances

🛠️ Custom Engineering Support

We offer custom impeller design based on your vessel size, material viscosity, temperature profile, and RPM range.

Whether for batch mixing, heat-sensitive compounds, or complex reactor geometries, our team ensures perfect integration with your existing equipment.

💡 Need a custom-built impeller for a jacketed vessel or a viscous process? Contact our design team to discuss your requirements.

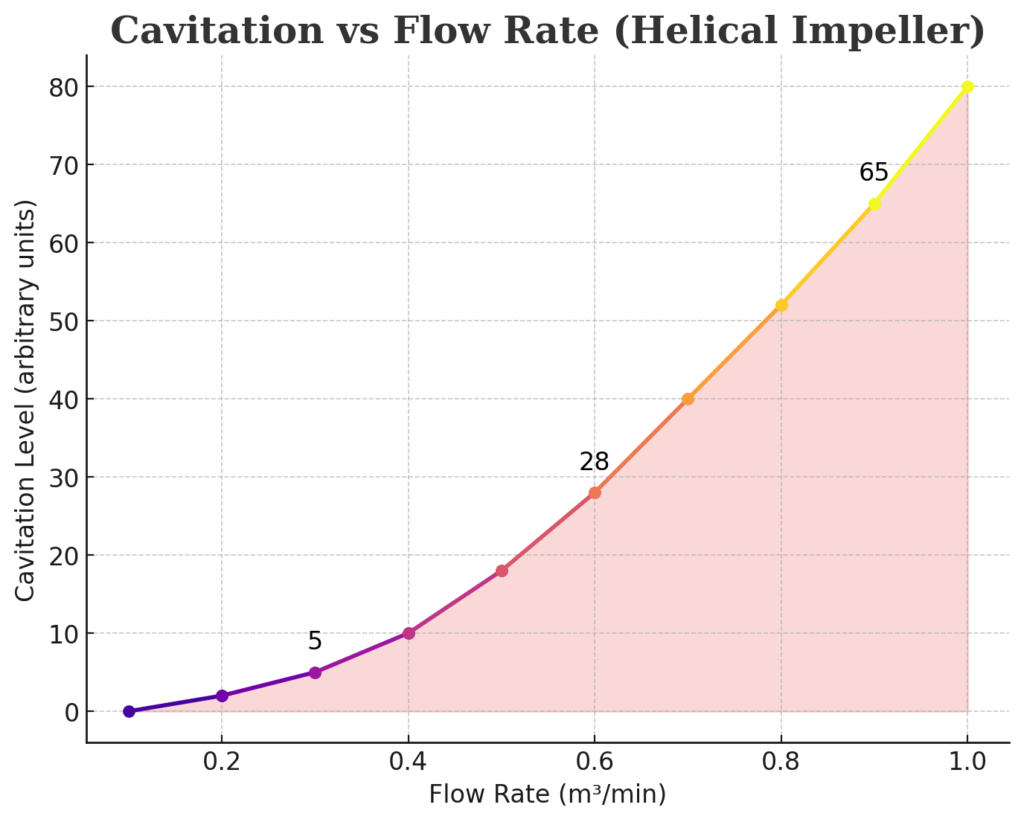

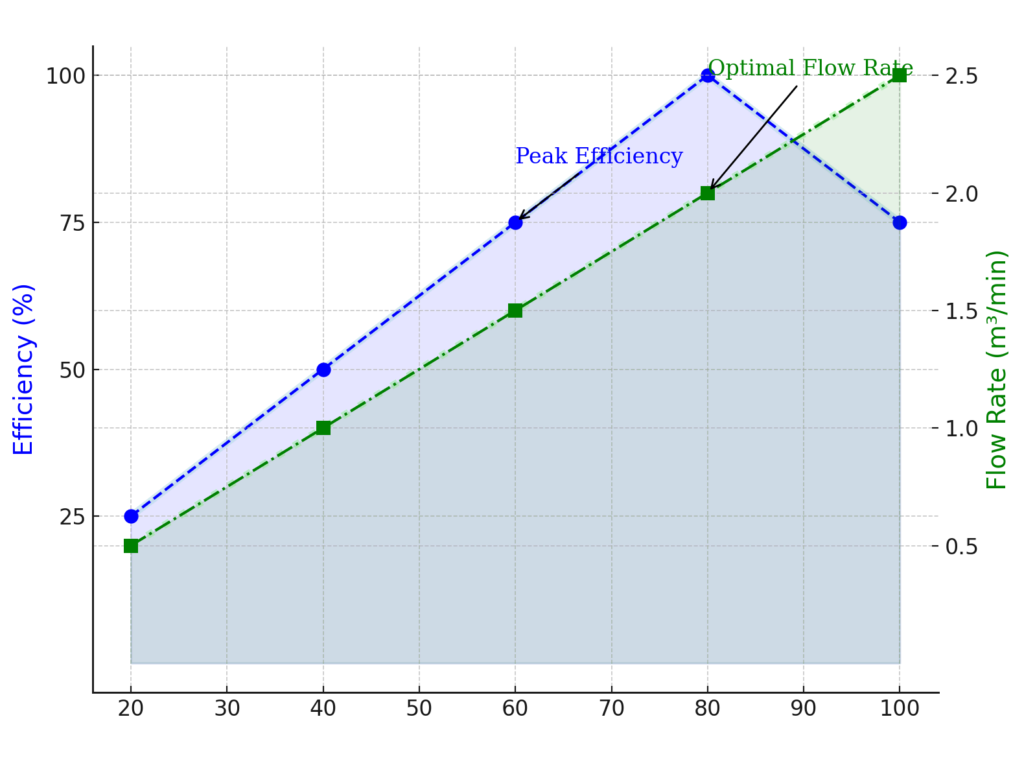

📊 Cavitation vs Flow Rate Chart Of Helical Impeller

Understanding the relationship between cavitation and flow rate is essential for optimizing the performance of your helical impeller in various industrial mixing applications. The chart below illustrates how different flow rates influence cavitation behavior and system stability.

📉 Why This Chart Matters

As flow rate increases, the risk of impeller cavitation also rises—especially when operating outside the optimal design range. Excessive cavitation can lead to vibration, noise, and mechanical wear, reducing the overall lifespan of the mixing system. This chart helps engineers identify the safe operational window for maximum efficiency and minimal equipment stress.

At SV Industries, our team ensures every helical impeller is designed to minimize cavitation through precise blade geometry and custom flow simulations. Learn more about how we ensure superior mixing efficiency on our Helical Impeller page.

Types of Helical Impellers and Their Applications

SV Industries offers a diverse range of Helical Impellers, each meticulously designed to handle specific viscous mixing challenges. Whether your goal is uniform blending, heat transfer, or wall-to-center flow, choosing the right impeller type significantly improves efficiency and product quality.

🔄 1. Single-Start Helical Impeller

Overview: One continuous helix around the shaft, promoting slow and steady axial flow.

Best for: Moderate to high-viscosity fluids in chemical and paint industries.

Key Features:

Low shear, ideal for shear-sensitive materials

Suitable for tall vertical vessels

Simple, cost-effective design

🌀 2. Twin Helical Impeller (Double Start Helix)

Overview: Two helical blades beginning from the shaft base to double the flow path.

Best for: High-efficiency blending of resins, cosmetics, and semi-solids.

Key Features:

Reduces blend time

Strong wall-to-center movement

Ideal for medium to very high viscosities

🎯 3. Ribbon Helical Impeller

Overview: A wide ribbon-like helix offering maximum contact area.

Best for: Sticky, paste-like, or elastic materials such as gels and waxes.

Key Features:

Enhanced scraping against vessel wall

Excellent for thermal mixing in jacketed vessels

Preferred for cosmetic and food-grade applications

⬇️ 4. Tapered Helical Impeller

Overview: Blade width and depth gradually decrease along the shaft.

Best for: Applications with variable viscosity zones in the same batch.

Key Features:

Improves axial circulation through thick and thin layers

Reduces energy spikes during mixing

Ideal for multiphase systems like suspensions

⚙️ 5. Conical Helical Impeller (Optional/Custom)

Overview: Designed to fit conical or sloped-bottom vessels.

Best for: Mixing in reactors where space narrows at the base.

Key Features:

Tailored for pressure reactors or conical fermenters

Excellent for complete bottom lifting of high-viscosity fluids

Available as part of custom agitator solutions

| Industry | Recommended Helical Impeller Type(s) |

|---|---|

| Pharmaceutical | Twin, Ribbon, Tapered |

| Adhesives | Ribbon, Single, Tapered |

| Paints & Coatings | Single, Tapered, Twin |

| Cosmetics | Ribbon, Conical, Twin |

| Food & Beverage | Tapered, Ribbon, Conical |

| Chemicals | Single, Twin, Conical |

| Petrochemical | Tapered, Twin |

| Resins & Polymers | Ribbon, Twin |

| Biotech | Conical, Twin |

| Lubricants | Ribbon, Single, Tapered |

🔌 Industry Applications at a Glance:

| Type | Best For | Flow Pattern | Viscosity Range |

|---|---|---|---|

| Single-Start Helical | Gums, syrups, slurries | Axial (bottom to top) | 5,000 – 50,000 cP |

| Twin Helical (Double Start) | Polymers, emulsions, adhesives | Axial + Radial hybrid | 10,000 – 100,000 cP |

| Ribbon Helical | High-solid pastes, creams | Radial + Wall scraping | 20,000 – 200,000 cP |

| Tapered Helical | Viscosity-gradient fluids | Controlled axial taper flow | 10,000 – 80,000 cP |

| Conical Helical | Conical-bottom tanks, biotech fluids | Bottom-focused spiral axial | 1,000 – 50,000 cP |

✅ Need guidance on choosing the right type? Explore our Industrial Stirrer Guide or Contact Us for expert help.

Materials Used in Our Helical Impellers

At SV Industries, we understand that material compatibility is critical to your industrial process. That’s why our Helical Impellers are crafted using high-grade materials selected for their durability, corrosion resistance, and application-specific performance.

✅ Common Materials We Use:

We offer a wide range of materials based on your process requirements, fluid properties, and regulatory standards:

🔹 Stainless Steel 316 (SS316):

Ideal for general-purpose mixing in food-grade and low-corrosive environments. It offers good mechanical strength and hygiene.

🔹 Stainless Steel 304 (SS304):

The industry standard for pharmaceuticals, chemicals, and marine applications. Known for excellent corrosion resistance against acids, alkalis, and chlorides.

🔹 Hastelloy C-276:

Best suited for high-strength and high-corrosion environments such as petrochemical or offshore industries. Offers higher durability and stress corrosion resistance than SS grades.

🔹 Duplex Steel:

A super-alloy used in extreme chemical conditions involving strong oxidizers, acids, and chlorinated solvents. Recommended for highly corrosive and high-temperature mixing applications.

🔒 Certifications & Compliance

All impellers can be delivered with MTC (Mill Test Certificate) upon request.

Our stainless steel components conform to ASTM A240 and ASME standards.

Food and pharma-grade impellers are CIP-friendly and available with polished surfaces for hygienic compliance.

🏭 Industry-Based Material Suitability:

| Industry | Preferred Material |

|---|---|

| Pharmaceutical | SS316 (Polished, CIP Friendly) |

| Food & Beverage | SS304 / SS316 |

| Chemical Processing | Hastelloy C-276 / SS316 |

| Paints & Coatings | SS304 / Duplex Steel |

| Cosmetics & Personal Care | SS316 (Polished) |

| Adhesives & Sealants | SS304 / Duplex Steel |

| Petrochemical | Duplex Steel / Hastelloy |

| Water Treatment | SS316 / Duplex Steel |

| Fertilizer Manufacturing | Duplex Steel |

| Marine & Offshore | Duplex Steel / SS316 |

We ensure that every impeller is built with precision and material excellence, keeping your process safety and longevity in focus.

Technical Specifications of Our Helical Impellers

At SV Industries, we manufacture precision-engineered Helical Impellers designed to meet the demanding needs of high-viscosity mixing applications across industries. Our impellers are available in a wide range of sizes, mounting options, and configurations—ensuring optimal performance and durability in every process.

Below is a quick overview of our standard specifications. Custom dimensions and RPM configurations can be tailored to your process requirements.

| Parameter | Specification |

|---|---|

| Shaft Diameter | 25 mm to 80 mm (customizable) |

| Impeller Diameter | 150 mm to 1200 mm |

| Speed Range (RPM) | 50 to 600 RPM |

| Mounting Type | Top Entry / Side Entry / Bottom Entry |

| Max Viscosity Handled | Up to 1,000,000 cP |

Our expert engineering team ensures compatibility with a wide range of agitator drives, tank sizes, and process conditions, making our Helical Impellers suitable for industries like pharmaceuticals, adhesives, chemicals, and more.

Need help choosing the right configuration for your process? Contact our team for a custom recommendation.

Industrial Applications of Helical Impellers

Helical Impellers are highly preferred in industries that require efficient mixing of high-viscosity or shear-sensitive fluids. At SV Industries, our expertly designed impellers offer consistent mixing results, ensuring process stability, reduced batch time, and optimized energy use.

Here are some of the major industries where our Helical Impellers deliver outstanding performance:

✅ Key Industry Use Cases:

| Industry | Typical Use Case |

|---|---|

| Pharmaceuticals | Ideal for mixing ointments, gels, and viscous drug formulations with controlled shear |

| Adhesive Manufacturing | Ensures uniform dispersion in glues, sealants, and epoxies |

| Food & Beverage | Used for blending sauces, syrups, dairy mixtures, and confectionery pastes |

| Paints & Coatings | Maintains suspension in thick emulsions and prevents sedimentation |

| Cosmetics | Supports uniform blending of creams, lotions, and high-viscosity gels |

| Chemical Processing | Suitable for polymer mixing, resin formulations, and thickeners |

| Petrochemicals | Effective for blending lubricants and high-viscosity additives |

| Water Treatment | Handles coagulation and polymer dosing in sludge treatment |

| Agrochemicals | Ensures homogenous mixing of fertilizers and plant-based viscous solutions |

| Construction Materials | Used for blending grout, tile adhesives, and textured coatings |

💧 Suitable Fluid Types:

High-viscosity fluids (up to 1,000,000 cP)

Shear-sensitive materials

Suspension-based slurries and semi-solids

Looking for more insight into where and how impellers are used in industry? Read our detailed impeller application guide on the blog.

Performance & Efficiency of Helical Impellers

When it comes to mixing viscous, shear-sensitive, or complex materials, Helical Impellers by SV Industries deliver exceptional performance with proven efficiency across a wide range of industrial processes. Engineered with a unique helical blade geometry, these impellers are built to optimize flow, reduce energy consumption, and improve product consistency.

📈 Key Performance Highlights:

🔹 Axial Flow Dominance

Our Helical Impellers promote strong axial flow, pushing the material from top to bottom. This ensures thorough mixing in tall tanks and minimizes dead zones—ideal for high-viscosity media.

🔹 Low Shear Mixing

The gradual spiral design generates minimal shear force, which protects sensitive materials like emulsions, gels, and active pharmaceutical compounds from degradation.

🔹 High Volumetric Flow Rate

Unlike radial-flow impellers, helical designs move larger volumes of fluid per revolution, making them highly energy-efficient for slow-speed, high-volume mixing.

🔹 Stable Torque Response

Helical impellers deliver consistent torque even under heavy-load conditions, resulting in stable motor performance and longer equipment life.

🔹 Viscosity Handling

Effectively handles viscosities up to 1,000,000 cP, making it suitable for industries like adhesives, cosmetics, and polymer processing.

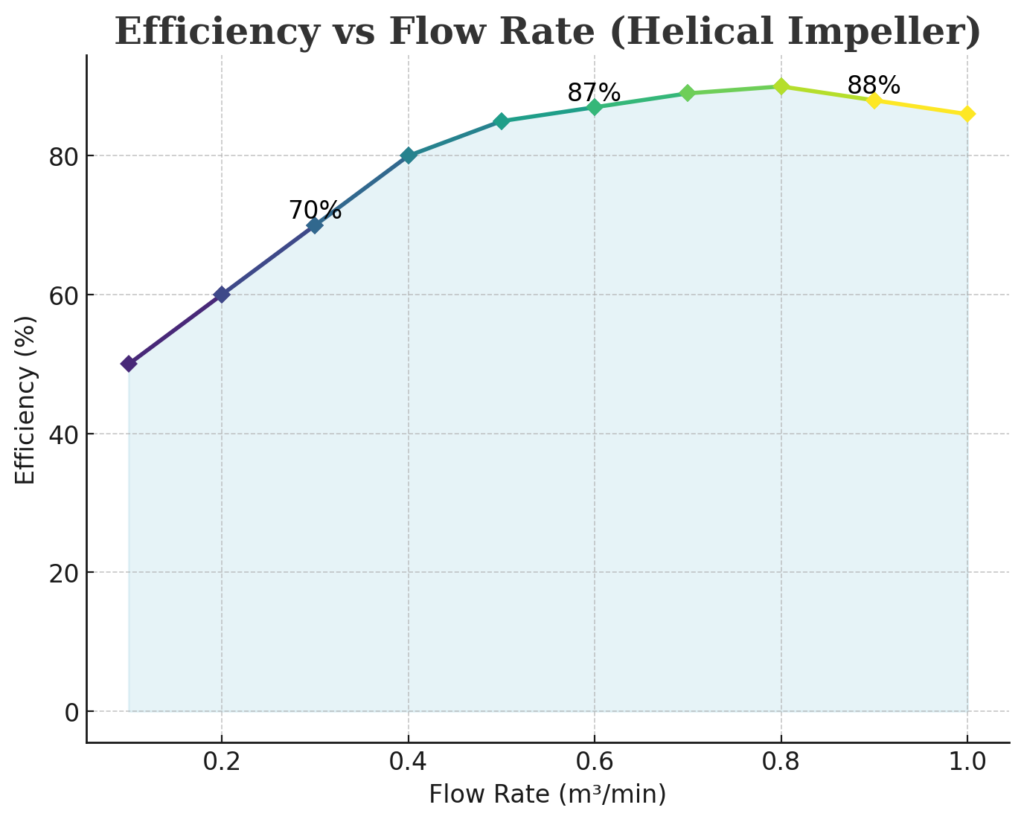

📊 Helical Impeller Efficiency vs Flow Rate Chart

The efficiency of a helical impeller is directly influenced by the flow rate, making this chart crucial for selecting the right operational parameters in your industrial mixing process.

📈 What the Chart Indicates

As shown, mixing efficiency typically increases with flow rate up to an optimal point—beyond which energy input rises disproportionately compared to output. This behavior helps process engineers determine the most energy-efficient operating range, minimizing power consumption while achieving effective fluid blending.

At SV Industries, we specialize in designing high-efficiency helical impellers for a wide range of applications. Our impellers are fine-tuned for low power draw and maximum throughput, helping industries reduce energy costs without compromising on performance. Explore our complete line of agitators and impellers engineered for performance and durability.

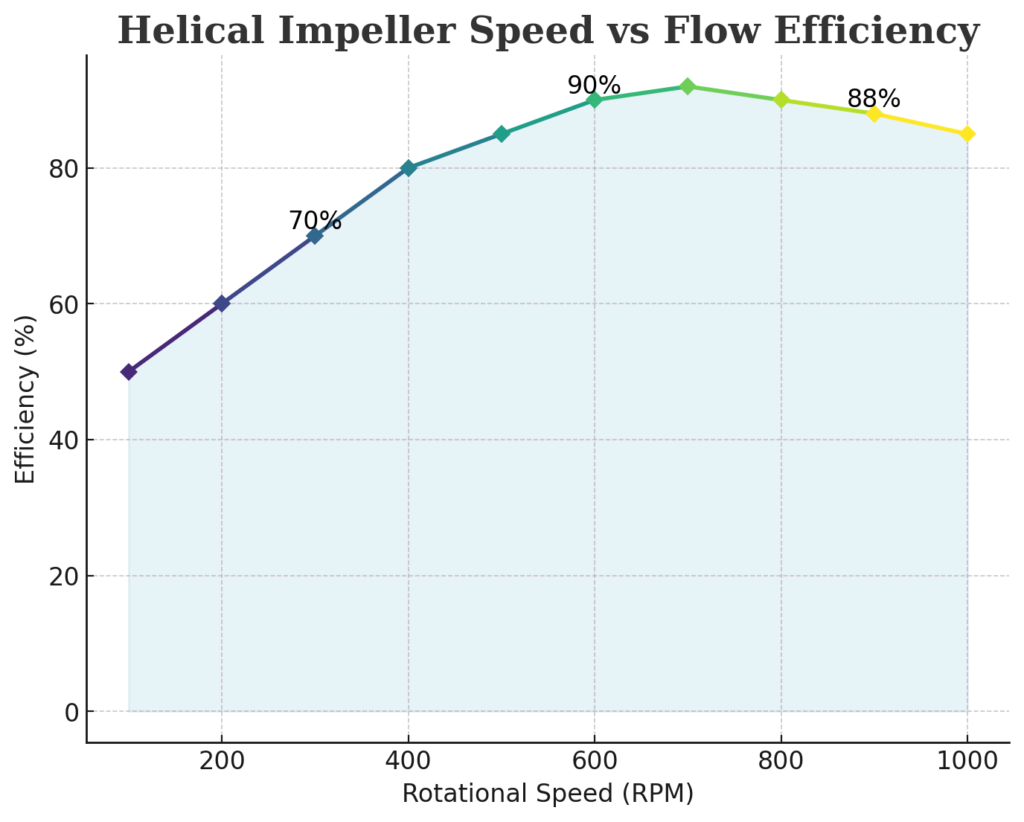

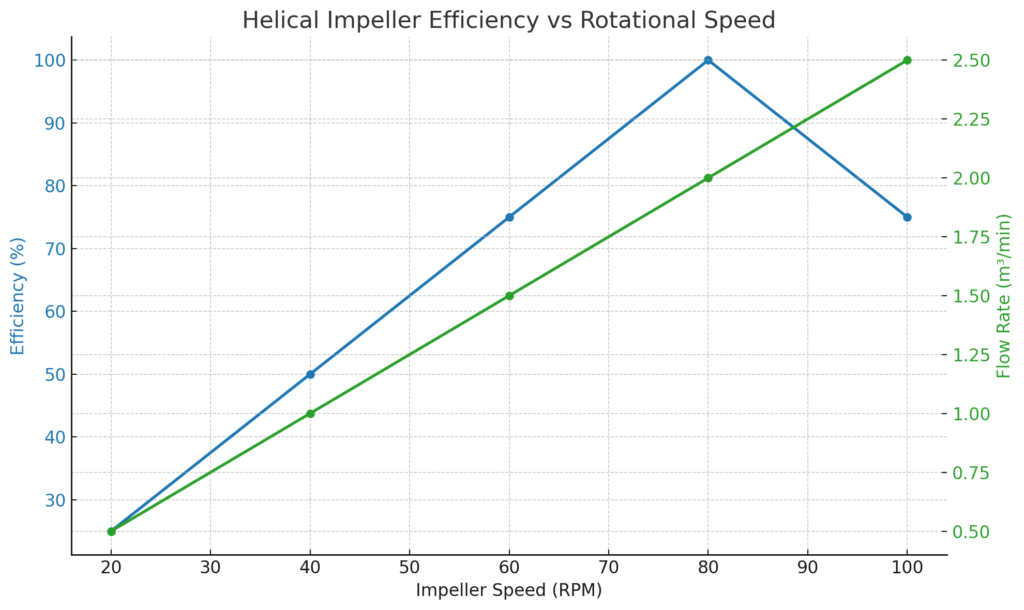

📊 Helical Impeller Speed vs Flow Efficiency Chart

This chart highlights the critical relationship between impeller rotational speed and the resulting flow efficiency in industrial mixing operations. Understanding this behavior is key to achieving optimal process performance while avoiding excess energy consumption or mechanical stress.

📈 What the Chart Indicates

As impeller speed increases, flow efficiency typically improves—up to a threshold. Beyond that point, gains in efficiency begin to plateau or even decline due to turbulent losses and potential cavitation. Identifying this sweet spot allows plant engineers to maintain stable flow dynamics with minimal energy input.

At SV Industries, we design precision-balanced helical impellers that perform efficiently across a wide speed range. Our in-house engineering ensures every impeller delivers maximum fluid displacement at optimal RPM, tailored for your specific reactor or vessel. Learn more on our Helical Impeller product page.

Need help determining the right speed for your application? Reach out to our experts via the contact form.

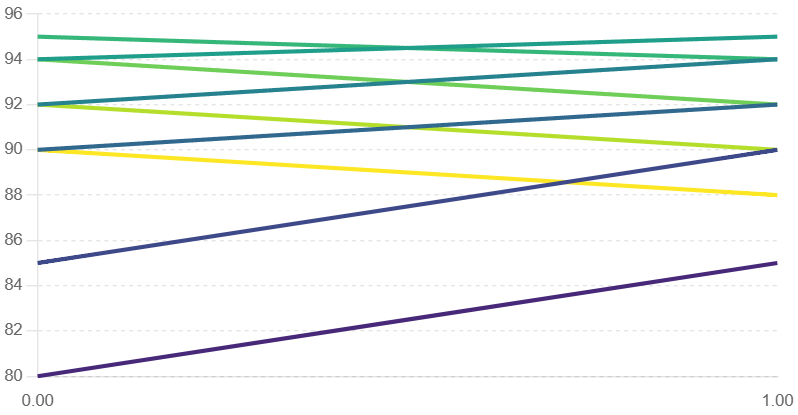

📊 Helical Impeller Speed vs Flow Efficiency vs Flow Rate Chart

This advanced chart presents a three-dimensional view of how impeller speed, flow efficiency, and flow rate interact in real-world mixing systems. Understanding these interdependencies helps engineers fine-tune operating parameters for maximum performance and energy savings.

📈 What the Chart Indicates

Increasing impeller speed generally improves flow rate and efficiency, but only within a balanced operating window. Pushing speed too high can lead to diminishing returns, increased power consumption, and even system instability. This chart visually identifies the optimal zone where all three variables align to deliver peak performance.

At SV Industries, we use advanced CFD simulations and in-house testing to engineer helical impellers that maintain ideal speed-to-flow efficiency ratios across a range of applications. Whether you’re handling viscous fluids or need high circulation rates, our agitator systems are built to deliver.

Ready to customize your impeller for top efficiency? Talk to our design experts via the contact page.

Power & Energy Consumption Analysis of Helical Impellers

One of the most common questions from plant engineers and procurement managers is:

“How much power does a Helical Impeller consume?”

At SV Industries, we understand the importance of operational efficiency. That’s why our Helical Impellers are designed not only for superior mixing performance but also for optimal energy usage—even in high-viscosity fluid applications.

🔋 Power Efficiency Insights:

🔹 Torque-Driven Design

Helical impellers operate on low RPM with high torque, meaning they move heavy, viscous materials with less speed, reducing wear and energy spikes.

🔹 Energy Input vs Output

Our impellers are tested for high volumetric flow per kW, ensuring more output with lower energy input. This translates to lower operational costs over time.

🔹 Motor Compatibility

Optimized to run efficiently with standard industrial motors (3-phase, 1440 RPM) and can be adapted for VFD-based systems for enhanced control and power savings.

🔹Stable Load Profile

Thanks to their gradual helix curve and consistent flow, our impellers avoid sudden torque fluctuations, reducing energy surges during batch runs.

🔹 Viscosity-Based Optimization

For fluids above 100,000 cP, we recommend pairing with gear reducers and low-speed drives—this maintains effective shear control without increasing energy consumption.

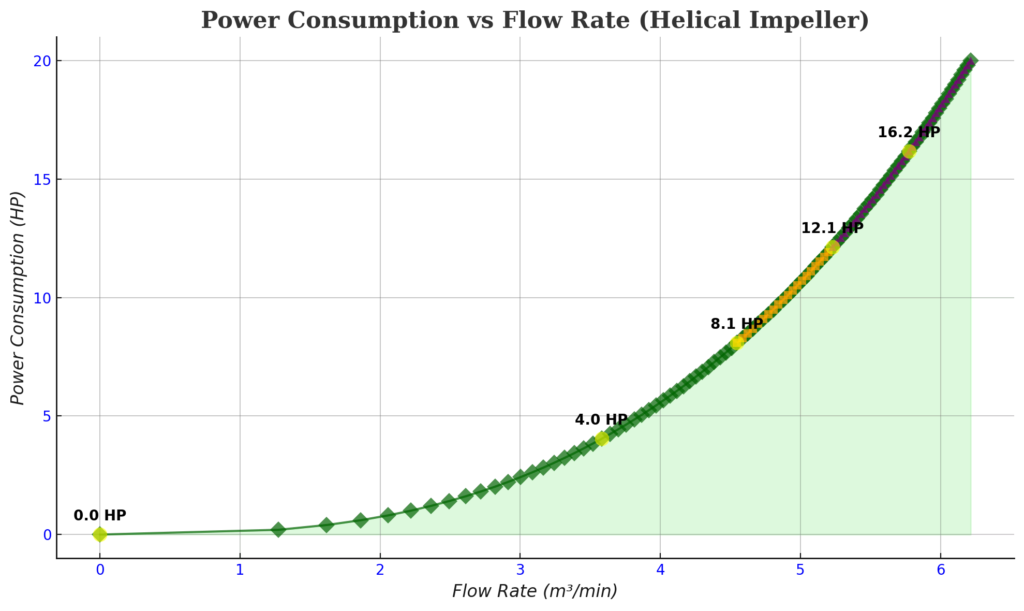

📊 Power Consumption vs Flow Rate in Helical Impellers Chart

Efficient mixing isn’t just about performance—it’s also about power economy. This chart demonstrates how power consumption varies with flow rate when using a helical impeller, helping engineers make energy-smart decisions in their process setup.

📈 What the Chart Indicates

As flow rate increases, power consumption also rises—though not always linearly. In the early stages, small power inputs can yield significant flow improvements. However, beyond a certain point, the curve steepens, indicating diminishing efficiency. Operating in this high-consumption zone may increase costs without proportionate process gains.

At SV Industries, our helical impellers are engineered to deliver maximum fluid movement at minimum energy input, ensuring that your industrial mixing processes remain both powerful and cost-efficient. Explore more on our Helical Impeller page or learn about our agitator solutions tailored for energy efficiency.

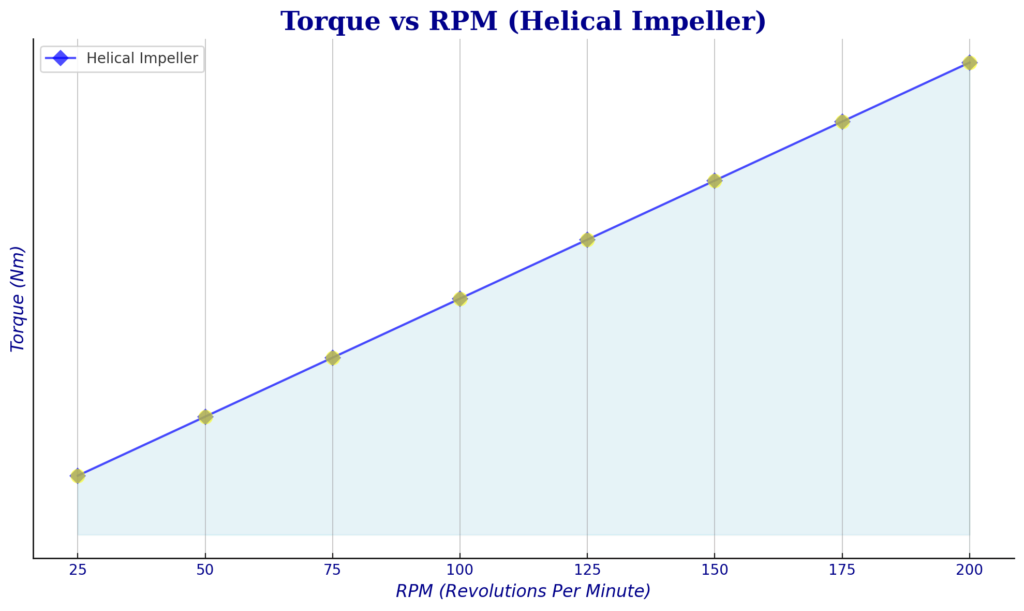

📊 Torque vs RPM in Helical Impellers Chart

This chart explains the relationship between torque and rotational speed (RPM) in helical impeller operations—a crucial factor in designing and operating efficient agitator systems for high-viscosity mixing.

📈 What the Chart Indicates

At lower RPMs, torque requirements are significantly higher, especially when mixing dense or viscous fluids. As RPM increases, torque demand typically decreases—but this comes with a trade-off in shear rate and mixing dynamics. Finding the ideal torque-RPM balance is key to avoiding motor overloads and ensuring long-term mechanical reliability.

At SV Industries, our helical impellers are designed with optimized torque profiles to ensure smooth startup, stable operation, and minimal strain on your mixing drive. Whether you’re processing chemicals, pharmaceuticals, or food-grade products, our custom agitator systems offer the right power-to-torque ratio for your needs.

Need help selecting the right RPM for your mixing setup? Connect with our engineering team via the Contact Us page.

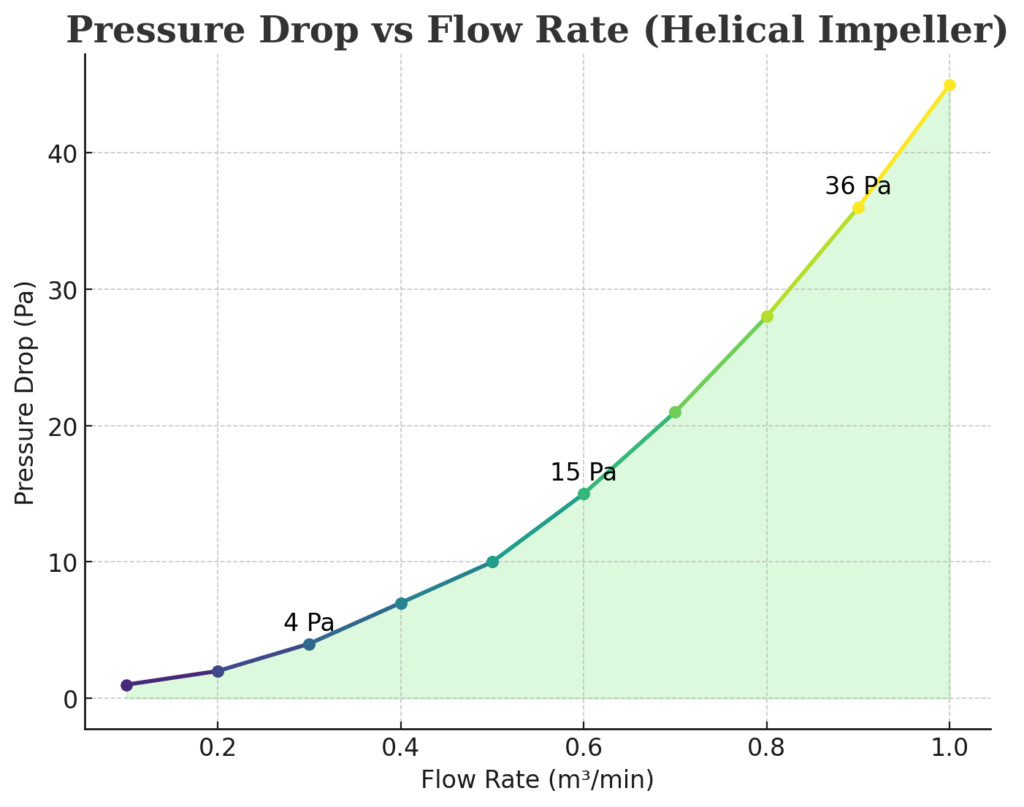

📊 Pressure Drop vs Flow Rate in Helical Impellers Chart

This chart illustrates the relationship between pressure drop and flow rate when using a helical impeller. It provides valuable insights into how increasing flow can affect system pressure and overall operational efficiency.

📈 What the Chart Indicates

As flow rate increases, the pressure drop also rises—especially in high-viscosity systems. This is a crucial consideration when selecting the right impeller and pump combination for your process. A higher pressure drop means more energy is required to maintain flow, which could lead to higher operational costs and strain on equipment.

At SV Industries, we optimize our helical impellers to minimize pressure drops, enhancing flow dynamics and energy efficiency. This ensures your systems run smoothly and cost-effectively, especially in complex mixing applications. Discover more about our solutions on the Helical Impeller product page.

Viscosity-Based Performance Metrics

Understanding how a Helical Impeller performs across different fluid viscosities is essential for selecting the right mixing solution. At SV Industries, our impellers are specifically engineered to deliver consistent, controlled mixing in both low-viscosity liquids and ultra-thick materials up to 1,000,000 cP.

🧪 How Helical Impellers Respond to Viscosity

🔹 Low to Medium Viscosity (1–10,000 cP)

In applications like chemical blending or solvent mixing, our helical impellers ensure fast turnover, gentle flow, and minimal air entrapment. Axial flow helps avoid splashing and improves uniformity.

🔹High Viscosity (10,000–100,000 cP)

For thicker fluids such as coatings, emulsions, and creams, the impeller’s spiral blade geometry generates progressive shear and flow layers, ensuring uniform distribution without damaging sensitive compounds.

🔹 Very High Viscosity (100,000+ cP)

In industries like adhesives, pastes, or high-solid suspensions, our impellers excel in bottom-to-top mixing. Pairing with gear reducers allows operation at lower RPMs to maintain energy efficiency while achieving effective material turnover.

🌀 Key Fluid Behaviors Observed:

Axial flow dominance: Prevents settling and dead zones even in high-viscosity tanks

Laminar flow patterns: Maintain product integrity for shear-sensitive materials

Consistent torque curve: Reduces motor stress during batch processing

High fill level compatibility: Performs efficiently even with >80% tank fill

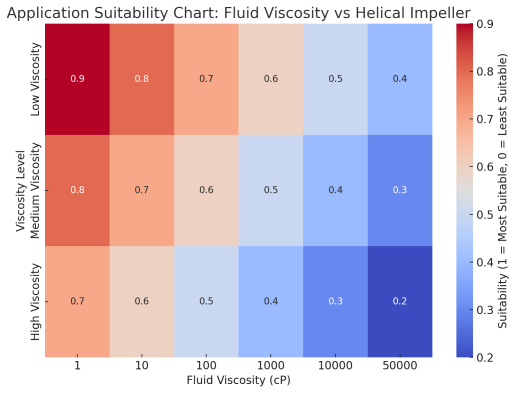

📊 Application Suitability: Fluid Viscosity vs Helical Impeller

This chart provides a practical overview of how helical impellers perform across various fluid viscosities, helping industries select the most suitable impeller type for their specific application needs.

📌 What This Chart Tells You

Helical impellers are especially well-suited for medium to high-viscosity fluids such as pastes, creams, polymers, adhesives, and slurries. As the fluid viscosity increases, their performance remains stable and effective, making them a top choice for laminar mixing applications. In contrast, for low-viscosity liquids, other impellers like the Rushton Turbine or Hydrofoil Impeller may be more appropriate.

At SV Industries, we help you choose the right impeller based on your process requirements—whether it involves high-viscosity fluid blending, heat-sensitive materials, or slow-speed agitation. Visit our Agitator Solutions page to explore more or get in touch for custom recommendations.

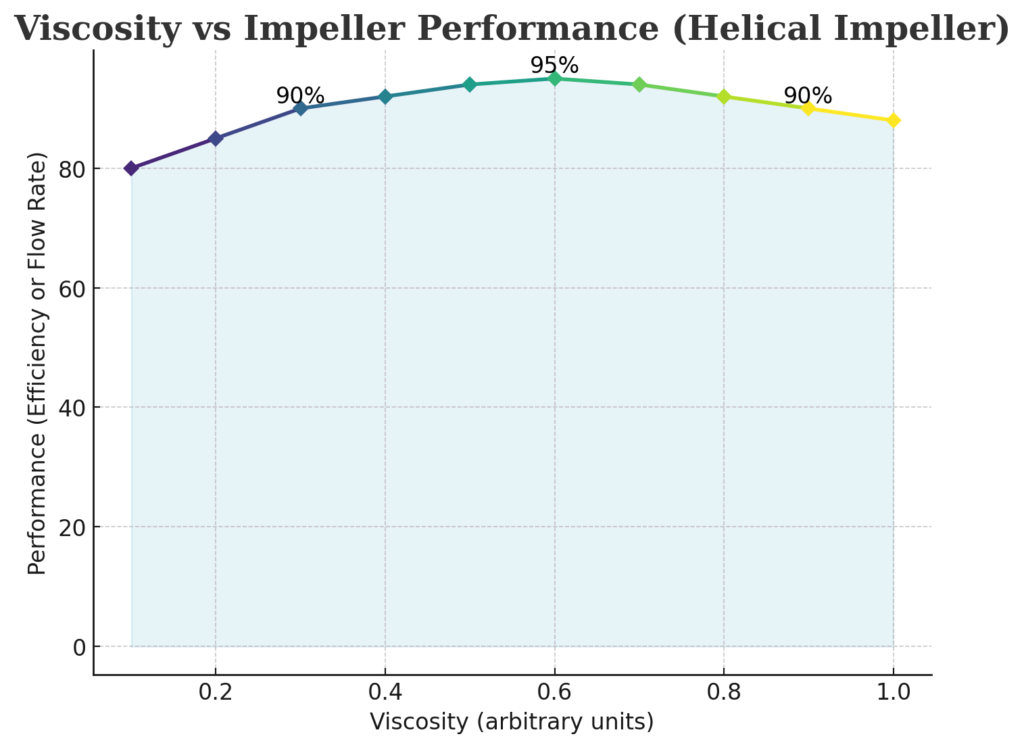

📊 Viscosity vs Impeller Performance in Helical Mixing Applications

Understanding how fluid viscosity impacts impeller performance is crucial for selecting the right mixing solution. This chart illustrates how helical impellers maintain efficient operation across a wide range of viscosities—making them ideal for industries that work with thick or shear-sensitive materials.

📈 What the Chart Indicates

As viscosity increases, the performance of many standard impellers drops sharply. However, helical impellers exhibit a steady and reliable performance curve, especially in the medium to high-viscosity range. Their large surface area and gentle flow design enable efficient axial mixing while preventing dead zones or excessive shear, which is critical for delicate or complex formulations.

At SV Industries, we specialize in manufacturing custom helical impellers tailored to your viscous fluid dynamics. Whether you’re mixing paints, gels, adhesives, or pharmaceutical slurries, our designs ensure consistent performance and long service life. Explore our Helical Impeller page for more insights or contact us for personalized support.

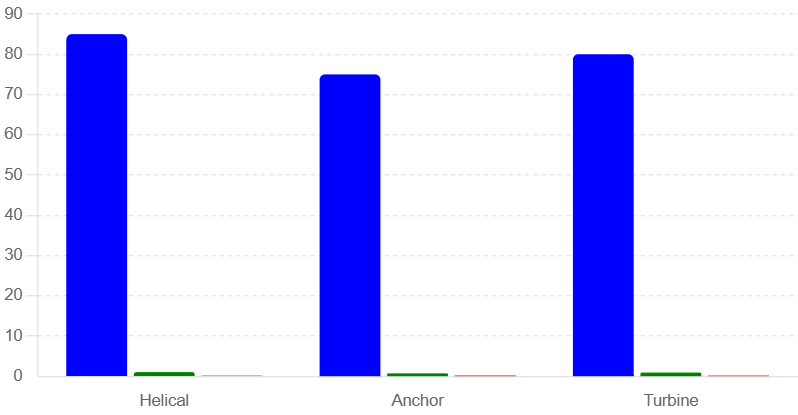

Impeller Type Comparison: Helical vs Anchor vs Turbine

Choosing the right impeller type is essential for achieving optimal mixing efficiency, product quality, and process consistency. Here’s a side-by-side comparison of three widely used impellers: Helical, Anchor, and Turbine, to help you make an informed decision based on your application, fluid type, and processing goals.

📊 Comparison Table: Helical vs Anchor vs Turbine Impeller

| Feature | Helical Impeller | Anchor Impeller | Turbine Impeller |

|---|---|---|---|

| Flow Pattern | Axial Flow (with gentle spiral motion) | Laminar Flow (sweeping wall contact) | Radial or Mixed Flow (depending on blade angle) |

| Best For | High-viscosity, shear-sensitive fluids | Highly viscous, paste-like materials | Low to medium viscosity fluids |

| Viscosity Range | Up to 500,000 cP | Above 200,000 cP | Below 50,000 cP |

| Energy Efficiency | High (less cavitation, efficient mixing) | Moderate (wall-sweeping helps prevent sedimentation) | High (ideal for rapid dispersion) |

| Mixing Behavior | Gentle folding, minimizes shear damage | Wall-scraping, minimal internal turbulence | High shear zones, fast mixing |

| Applications | Adhesives, polymers, ointments | Chocolate, creams, resins | Paints, dyes, fermentation |

| Maintenance | Low (self-cleaning profile) | Moderate (may require regular inspection) | Low (standardized parts) |

At SV Industries, we specialize in all three impeller types:

👉 Helical Impeller

👉 Anchor Impeller

👉 Turbine Impeller

Not sure which is right for your process? Our team can guide you based on your fluid properties, tank design, and production goals.

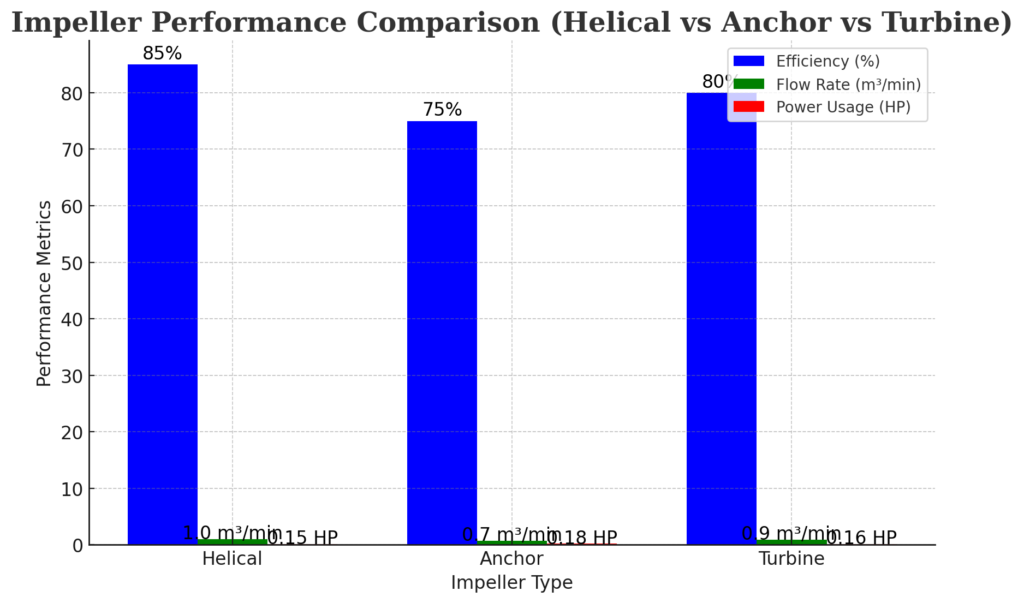

📊 Viscosity vs Impeller Performance in Helical Mixing Applications

Choosing the right impeller type is essential for achieving optimal mixing performance. This comparison chart provides a clear overview of how Helical, Anchor, and Turbine impellers perform across key parameters like viscosity handling, flow pattern, energy efficiency, and application suitability.

📈 What the Chart Indicates

Helical Impellers excel in high-viscosity fluids, delivering strong axial flow and gentle agitation, making them perfect for laminar mixing and shear-sensitive processes.

Anchor Impellers (see Anchor Impeller Page) are great for very high-viscosity applications with slow-speed mixing and full vessel wall wiping action, ensuring no material is left unmixed.

Turbine Impellers, like the Rushton Turbine, are ideal for low to medium-viscosity liquids, providing high shear and intense radial mixing—suitable for gas-liquid and liquid-liquid processes.

Each impeller has a specific performance advantage depending on your process needs. At SV Industries, our experts help you choose the best impeller configuration based on your fluid properties, batch volume, and process goals.

Explore our complete Agitator solutions or get in touch for a custom mixing solution tailored to your industry.

Benefits of Choosing Our Helical Impellers

When it comes to mixing high-viscosity or shear-sensitive fluids, not all impellers are created equal. At SV Industries, our Helical Impellers are designed with precision engineering and industrial-grade durability to meet the toughest process requirements. Here’s why engineers across industries trust our solutions:

💧 Superior Flow Handling

Our helical blades generate a strong axial flow, ensuring complete top-to-bottom circulation in tanks. This allows efficient mixing of dense, viscous, or layered materials—eliminating dead zones and improving batch homogeneity.

🌀 Reduced Cavitation & Shear Damage

Thanks to their spiral geometry and low RPM operation, our impellers create smooth, laminar flow patterns that minimize cavitation risks and protect shear-sensitive ingredients—ideal for pharmaceuticals, adhesives, and emulsions.

⚙️ Energy-Efficient Mixing

Helical impellers from SV Industries deliver maximum output with minimal power input. The high torque, low-speed operation is perfect for reducing operational costs—especially with gear-driven or VFD systems.

🔩 Built for Longevity

Crafted from premium materials like SS316, Hastelloy, and Duplex Steel, our impellers are resistant to corrosion, abrasion, and process wear. Polished surfaces make them CIP-friendly and easy to maintain for long-term use.

🧪 Efficient Fluid Flow

The continuous, spiral movement generated by the blades creates optimal radial and axial flow, ensuring uniform mixing and suspension of solids.

🔄 Customizable Designs

Our impellers can be tailored to suit specific applications, with adjustable blade angles and configurations for enhanced mixing efficiency.

📈 Trusted by Industry Leaders

From chemical reactors to food-grade mixers, our impellers are used across industries for their proven reliability and consistent performance.

Helical Impeller Manufacturers & Suppliers in India – What You Need to Know

When selecting a helical impeller for your mixing application, choosing the right manufacturer and supplier can make all the difference. With growing demand across the pharmaceutical, chemical, and food industries, it’s important to understand how these providers operate and how to choose the best one for your needs.

🔧 What Does a Helical Impeller Manufacturer Do?

A helical impeller manufacturer is responsible for:

Designing the impeller geometry (helix angle, blade width, pitch, etc.)

Selecting the right materials like SS316, Hastelloy, or Duplex Steel

Ensuring compatibility with different shaft types and mounting systems

Providing custom fabrication based on viscosity, flow rate, and tank configuration

Performing quality checks and certifications for GMP or food-grade compliance

At SV Industries, every impeller is engineered for high performance and long-term durability in viscous and shear-sensitive applications.

📦 What Does a Helical Impeller Supplier Do?

A supplier bridges the gap between manufacturer and end-user. Their role includes:

Maintaining ready stock or fast lead times

Offering technical guidance and product selection support

Providing after-sales service, including installation, commissioning, and support

Ensuring compliance with industry standards for your specific application

Suppliers like SV Industries not only manufacture but also serve as end-to-end solution providers, giving clients peace of mind from design to delivery.

✅ How to Choose the Right Helical Impeller Vendor in India

Here are some quick tips:

✅ Check for custom design capability based on fluid type and reactor design

✅ Ask about material certifications and prior experience in your industry

✅ Compare lead times, pricing, and support responsiveness

✅ Ensure they offer installation guidance or detailed product documentation

✅ Prefer a vendor who can supply related equipment like agitators or reactor vessels

Whether you need a single impeller or a complete mixing solution, a trusted Indian supplier like SV Industries can help you optimize performance while keeping costs low.

Why SV Industries is the Right Choice for Helical Impellers

Choosing the right helical impeller manufacturer can significantly impact your process efficiency and long-term performance. At SV Industries, we bring unmatched value through our:

Custom-engineered designs tailored to your mixing requirements

On-time delivery backed by streamlined production and logistics

Expert technical support and dedicated service team available pre- and post-installation

State-of-the-art manufacturing facility equipped to handle small to large-scale production with high precision

With a strong focus on quality, durability, and performance optimization, our team ensures every helical impeller is crafted to deliver maximum mixing efficiency in demanding industrial environments.

We serve a growing base of satisfied clients across India, supported by a responsive service team and a robust manufacturing setup.

Want to know more about our agitator and impeller solutions? Explore our full range of industrial agitators and impeller types designed for modern mixing challenges.

Frequently Asked Questions (FAQs) about Helical Impeller

What is a helical impeller used for?

Helical impellers are used for mixing, blending, and suspending materials in applications that require low shear and efficient flow, such as in chemical, pharmaceutical, and food processing industries.

How does a helical impeller work?

A helical impeller works by rotating its spiral-shaped blades, creating a continuous, smooth flow of liquid, with both axial and radial flow patterns, ensuring effective mixing and solid suspension.

What industries use helical impellers?

Helical impellers are commonly used in chemical processing, pharmaceuticals, food and beverage, water treatment, and cosmetics industries.

What are the benefits of the helical design?

The helical blade design provides low shear, efficient mixing, and uniform flow, which is essential for blending high-viscosity fluids and sensitive materials.

Can SV Industries' helical impellers handle high-viscosity fluids?

Yes, they are ideal for mixing high-viscosity fluids, suspensions, and emulsions with minimal shear force.

Are helical impellers energy-efficient?

Yes, SV Industries’ helical impellers are designed to operate efficiently, reducing energy consumption while providing optimal mixing performance.

What materials are used in SV Industries' helical impellers?

Our helical impellers are made from stainless steel, corrosion-resistant alloys, and other durable materials that can withstand harsh environments.

What maintenance is required for helical impellers?

Regular inspection and cleaning are recommended to ensure long-lasting performance. Minimal maintenance is required due to the durable design.

How do I order a helical impeller from SV Industries?

Contact our sales team to discuss your specific requirements, and we will provide you with a customized impeller solution tailored to your needs.

Are SV Industries' helical impellers customizable?

Yes, we offer custom-designed helical impellers with adjustable blade configurations and angles to meet your specific mixing requirements.