Reactor Vessel Manufacturer and Supplier in India

At SV Industries, we are recognized as one of the leading reactor vessel manufacturers in India, delivering high-quality and customized solutions for industries such as chemicals, pharmaceuticals, petrochemicals, food & beverages, and specialty chemicals. With decades of engineering expertise, modern fabrication facilities, and adherence to international standards, we ensure every reactor vessel is designed for durability, safety, and superior performance.

Unlike generic suppliers, SV Industries combines technical excellence with process understanding—making us a trusted partner for companies that need precision-built vessels. Whether you require limpet coil reactor vessels for efficient heating and cooling, SS jacketed vessels for temperature-sensitive operations, or fully customized chemical process reactors, our team delivers solutions tailored to your exact needs.

✔️ Why Choose SV Industries?

Manufacturing as per ASME / DIN / IS standards.

Wide capacity range: 100 Liters to 50,000 Liters.

Expertise in designing, fabricating, and supplying reactors across India.

Advanced agitation systems using Anchor Impellers, Pitch Blade Turbines, Rushton Turbines, and more.

End-to-end support: Design → Fabrication → Installation → After-sales.

If you are looking for a reliable industrial reactor supplier in India, SV Industries is your one-stop solution. Explore our reactor vessel range or contact us for customized designs that meet your process requirements.

What is a Reactor Vessel?

A reactor vessel is a specially designed container used in industries to carry out chemical reactions under controlled pressure, temperature, and mixing conditions.

It acts as the core equipment of process industries, ensuring safe, efficient, and consistent production.

📖 Detailed Explanation

In simple terms, a reactor vessel provides a closed environment where raw materials are introduced, mixed, and reacted to form desired products. Its design allows engineers to maintain critical process parameters such as:

Temperature (through heating/cooling jackets or limpet coils)

Pressure (from full vacuum up to 60 bar)

Mixing intensity (using high-efficiency agitators and impellers)

Reaction time (controlling residence time for better yields)

At SV Industries, our industrial chemical reactors are designed for diverse applications such as polymerization, hydrogenation, blending, and crystallization. We use premium materials like SS 304, SS 316, SS 316L, and alloy steels, ensuring long service life even under corrosive and high-pressure environments.

⚙️ Key Roles of a Reactor Vessel:

Containment of reactants and products.

Heat transfer for maintaining process temperature.

Efficient agitation for homogenous mixing.

Pressure handling for safe reactions.

Easy integration with automation and process monitoring systems.

With SV Industries, you get not just a vessel, but a reliable backbone for your entire production process, designed to maximize safety, efficiency, and product quality.

👉 Want to explore specific designs like SS Jacketed Vessels? Check our dedicated page here.

How Does a Reactor Vessel Work?

A reactor vessel works by safely containing raw materials, maintaining temperature and pressure, and using agitation to ensure proper mixing and controlled chemical reactions.

It creates a stable environment for efficient and safe production.

⚙️ Detailed Working Principle

A reactor vessel integrates multiple systems to achieve reliable chemical processing:

Containment of Reactants 🧪

Raw materials are introduced into the vessel through nozzles and manways. The vessel provides a secure, leak-proof environment to prevent contamination or loss.Agitation & Mixing 🔄

High-efficiency agitators with different impellers — such as Anchor, Pitch Blade Turbine, or Rushton Turbine — are installed to ensure uniform mixing of reactants, catalysts, and solvents.Temperature Control 🌡️

Heating: Steam, hot oil, or electric systems via SS Jacketed Vessels.

Cooling: Circulating chilled water or brine through limpet coil reactor vessels.

This ensures reactions occur at optimal temperatures.

Pressure Regulation ⚡

Designed to handle full vacuum up to 60 bar, ensuring safety during high-pressure reactions. Relief valves, gauges, and automation systems are integrated for protection.Reaction & Conversion 🔬

Inside the vessel, the controlled environment allows reactants to transform into desired products — whether through polymerization, blending, hydrogenation, or crystallization.Monitoring & Control 📊

Automation sensors track temperature, pressure, mixing speed, and reaction progress, enabling precision control and repeatability.

📌 Why This Matters

The efficiency of a reactor vessel directly impacts:

Product yield & quality

Process safety & reliability

Energy consumption & cost-effectiveness

That’s why industries trust SV Industries for advanced chemical process reactors designed with technical precision and application-specific customization.

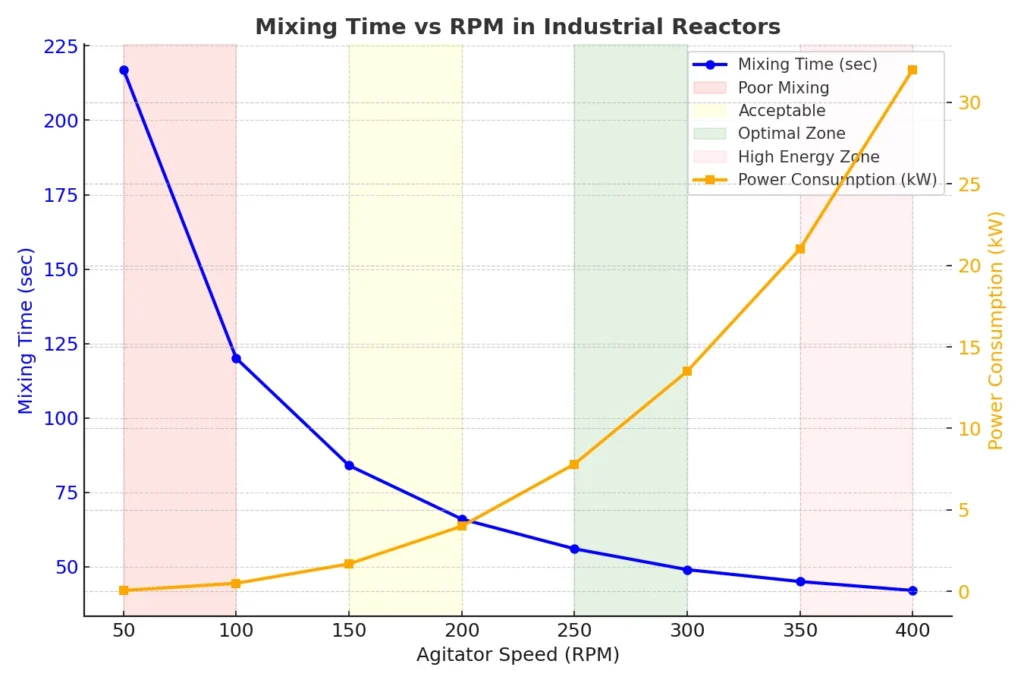

📊 Mixing Time vs RPM in Industrial Reactors

Mixing time is one of the most critical parameters in Industrial Chemical Reactor design, as it directly influences product uniformity, reaction speed, and process efficiency. The chart below demonstrates the relationship between agitator RPM and mixing performance, while also highlighting the power cost trade-off at higher speeds.

💡 Insight & Analysis

From the chart, it is clear that:

Low RPM (50–100) results in poor mixing and longer times (>200 sec).

150–200 RPM offers acceptable performance but not fully optimized.

Optimal zone (250–300 RPM) achieves >50% faster mixing with reasonable energy use.

Beyond 350 RPM, mixing time improves only slightly, but power demand rises sharply, increasing operational cost.

This demonstrates why SV Industries’ reactor design focuses on achieving high mixing efficiency at optimal speeds, ensuring energy savings, reduced batch times, and superior quality output. As a trusted reactor vessel manufacturer and industrial reactor supplier in India, SV Industries helps industries optimize reactor applications in chemicals, pharmaceuticals, and specialty manufacturing.

Reactor Vessel Design and Engineering by SV Industries

At SV Industries, we combine advanced engineering expertise with decades of manufacturing experience to deliver reactor vessels designed for precision, safety, and efficiency. Our design philosophy goes beyond standard fabrication — we focus on process understanding, customization, and long-term reliability, making us a trusted reactor vessel manufacturer in India.

🔬 Core Design Principles

Our engineering team follows strict international codes such as ASME, DIN, and IS standards, ensuring every vessel meets safety and performance benchmarks. Each design is optimized for:

Material Selection 🛡️ – Stainless Steel (SS 304, SS 316, SS 316L), Mild Steel, or special alloys for corrosion & temperature resistance.

Pressure & Temperature Ratings 🌡️ – From full vacuum to 60 bar and -20°C to 300°C operating range.

Mixing Efficiency 🔄 – High-performance agitators including Anchor Impellers, Paddle Impellers, Rushton Turbines, and Helical Impellers.

Thermal Control Systems ⚡ – Choice of SS Jacketed Vessels or Limpet Coil Reactors for efficient heating and cooling.

Process Integration 📊 – Equipped with automation-ready nozzles, manways, valves, and instrumentation for seamless plant integration.

📊 Typical Design Parameters (Range)

| Design Factor | Specification Range |

|---|---|

| Capacity | 100 Liters – 50,000 Liters |

| Design Pressure | Vacuum to 60 bar |

| Operating Temperature | -20°C to 300°C |

| Agitation Speed | 20 – 150 RPM (customizable) |

| Surface Finish | Matte, 2B, Mirror Finish (for Pharma & Food) |

| Certifications | ASME Sec VIII Div. 1, GMP compliant (where required) |

💡 Why SV Industries for Reactor Design?

In-house CAD/CAM based design & simulation.

Experience across chemical, pharma, petrochemical, and food industries.

Proven expertise in custom reactor design for complex processes.

Strong track record as a leading industrial reactor supplier.

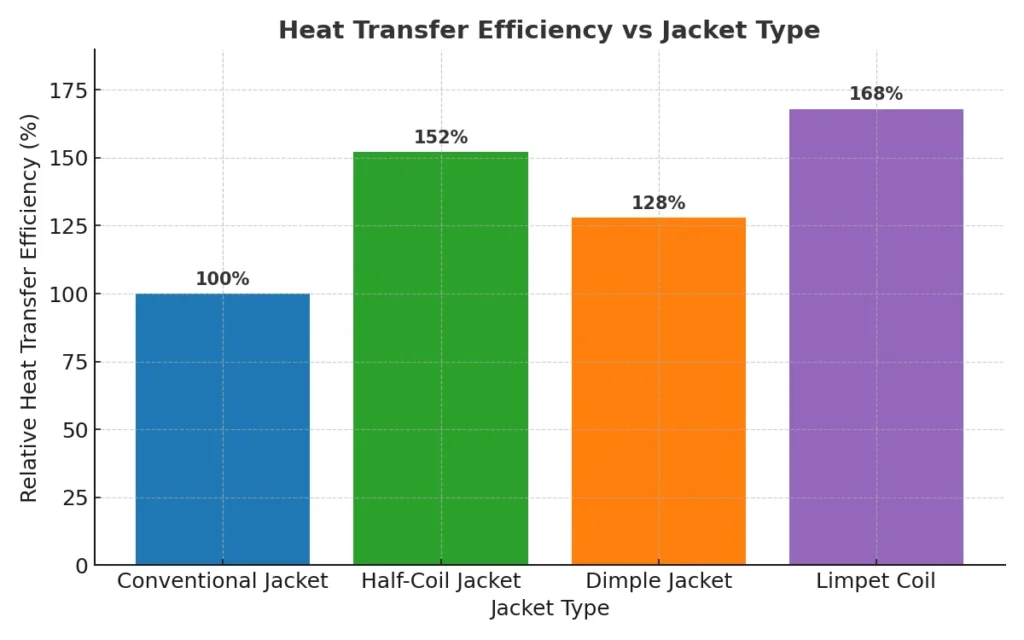

🌡️ Heat Transfer Efficiency vs Jacket Type in Industrial Reactors

Heat transfer performance is a critical factor in Industrial Chemical Reactor design, as it directly influences heating/cooling time, batch consistency, and energy cost. The chart below compares the heat transfer efficiency of different jacket types commonly used in reactors, enabling buyers to evaluate the best solution for their process needs.

💡 Insight & Analysis

From the comparison, it is clear that:

Conventional Jackets provide standard performance but limited turbulence.

Dimple Jackets offer 28% higher efficiency due to increased surface area and rigidity.

Half-Coil Jackets deliver ~52% better performance, ensuring faster heat exchange.

Limpet Coils outperform all with ~68% higher efficiency, ideal for high-temperature and high-pressure applications.

This demonstrates how SV Industries’ expertise in reactor design allows us to recommend the right jacket system — ensuring energy savings, shorter cycle times, and consistent product quality. As a leading reactor vessel manufacturer and supplier in India, we provide tailored jacket designs for chemical, pharma, and specialty industries worldwide.

📞 Partner with SV Industries for innovative reactor vessel design that matches your process needs with engineering perfection. Get in touch today.

Materials and Quality Standards in Reactor Vessel Manufacturing

At SV Industries, we believe that the material of construction (MOC) and strict adherence to quality standards define the durability, safety, and performance of every reactor vessel. As a trusted reactor vessel manufacturer in India, we carefully select materials based on the process requirements, ensuring corrosion resistance, thermal stability, and compliance with international norms.

🔧 Common Materials Used in Reactor Vessels

| Material | Key Properties | Applications |

|---|---|---|

| SS 304 | Good corrosion resistance, cost-effective, easy to fabricate | Food, beverage, general chemical processes |

| SS 316 / 316L | Excellent resistance to acids, chlorides, and high temperatures | Pharmaceutical, specialty chemicals, petrochemicals |

| Mild Steel (MS) | High strength, economical, suitable for non-corrosive duties | Bulk chemical storage, low-cost processes |

| Alloy Steels | Enhanced strength, wear & heat resistance | High-pressure, high-temperature reactors |

| Glass-Lined / PTFE-Lined | Superior anti-corrosion, smooth non-stick surface | Aggressive chemical reactions, pharmaceutical applications |

📐 Quality Standards We Follow

Every SV Industries reactor vessel is engineered as per global codes and certifications, ensuring reliability and compliance.

✅ ASME Section VIII, Div. 1 (Design & Fabrication)

✅ DIN & IS Standards for pressure vessels

✅ GMP Compliance for pharma & food-grade vessels

✅ Hydro & Pneumatic Testing for leak-proof safety

✅ Welding Standards (WPS/PQR approved) for strength & durability

✅ Surface Finishes – Matte, 2B, Mirror Polish, as per industry needs

💡 Why This Matters to Buyers?

Long service life with reduced downtime

Safe operations under extreme conditions

Compatibility with corrosive & high-temperature processes

Confidence that your equipment meets international quality benchmarks

👉 Check our specialized designs like SS Jacketed Vessels and Limpet Coil Reactors to see how materials impact thermal efficiency and performance.

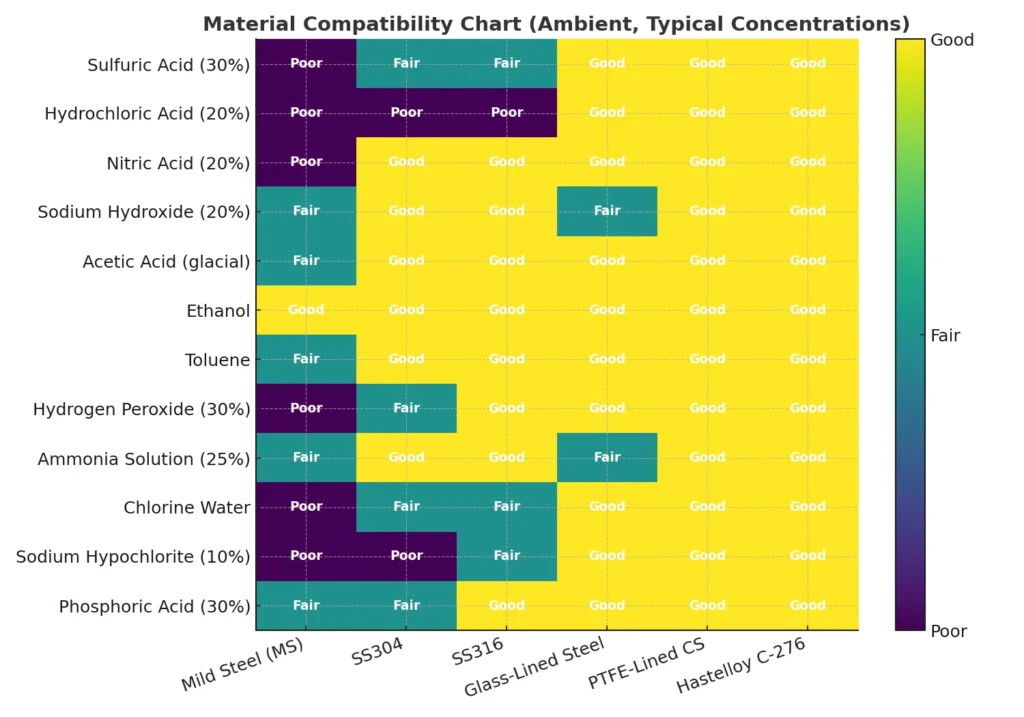

⚗️ Material Compatibility Chart (Ambient, Typical Concentrations)

Material selection directly impacts safety, reliability, and lifecycle cost of an Industrial Chemical Reactor. This chart summarizes chemical compatibility across common materials—MS, SS304, SS316, Glass-Lined, PTFE-Lined, Hastelloy C-276—to guide buyers during reactor design and procurement.

💡 Insight & Analysis

Acids with chlorides (HCl, hypochlorite) rapidly attack stainless steels; Glass-Lined / PTFE / Hastelloy are preferred.

Nitric acid favors stainless steels; MS is poor.

Strong alkali (NaOH) is generally fine for SS316/PTFE/Hastelloy; glass lining can be limited at higher temp.

Oxidizers (H₂O₂, chlorinated media): SS316 fares better than SS304, but lined or nickel-based alloys give robust margins.

SV Industries helps match process chemistry, temperature, and concentration to the right material (including GLS, PTFE lining, and high-nickel alloys), reducing corrosion risk and downtime.

⚠️ Disclaimer: Ratings are indicative at ~25 °C; always validate with exact concentration, temperature, contaminants, chloride level, and applicable standards before finalizing.

Technical Specifications of Reactor Vessels (Typical Range)

Every process is unique, and so are the technical requirements of a reactor vessel. At SV Industries, we design and manufacture vessels across a wide capacity and operating range, ensuring optimum safety, performance, and compliance with international codes.

Here is a typical specification range for our industrial reactor vessels:

| Parameter | Specification Range |

|---|---|

| 1. Capacity | 100 Liters – 50,000 Liters |

| 2. Design Pressure | Full Vacuum up to 60 bar |

| 3. Operating Temperature | -20°C to 300°C |

| 4. Material of Construction (MOC) | MS, SS 304, SS 316, SS 316L, Alloy Steels, Glass/PTFE Lined |

| 5. Vessel Orientation | Vertical / Horizontal |

| 6. Head Type | Flat, Dished, Torispherical, Ellipsoidal |

| 7. Agitation Options | Anchor Impeller, Pitch Blade Turbine, Paddle Impeller, Rushton Turbine, Helical Impeller, Hydrofoil |

| 8. Agitation Speed | 20 – 150 RPM (customizable) |

| 9. Heating Options | Steam, Hot Oil, Electrical Heating |

| 10. Cooling Options | SS Jacketed Vessel, Limpet Coil Reactor |

| 11. Surface Finish | Matte, 2B, Mirror Polish (GMP Compliant) |

| 12. Nozzle Configurations | Inlet, Outlet, Vent, Manway, Instrumentation Ports |

| 13. Drive Type | Top Entry / Side Entry / Bottom Entry |

| 14. Sealing Options | Mechanical Seal, Lip Seal, Stuffing Box |

| 15. Insulation | Single / Double Insulation with Cladding |

| 16. Lining Options | Glass-Lined, PTFE, Rubber Lining |

| 17. Testing | Hydro Test, Pneumatic Test, NDT (as required) |

| 18. Certifications | ASME Sec VIII Div.1, DIN, IS Standards, GMP |

| 19. Automation Compatibility | PLC/DCS Integration with Sensors (Temp, Pressure, RPM) |

| 20. Customization | Fully tailor-made design as per client requirement |

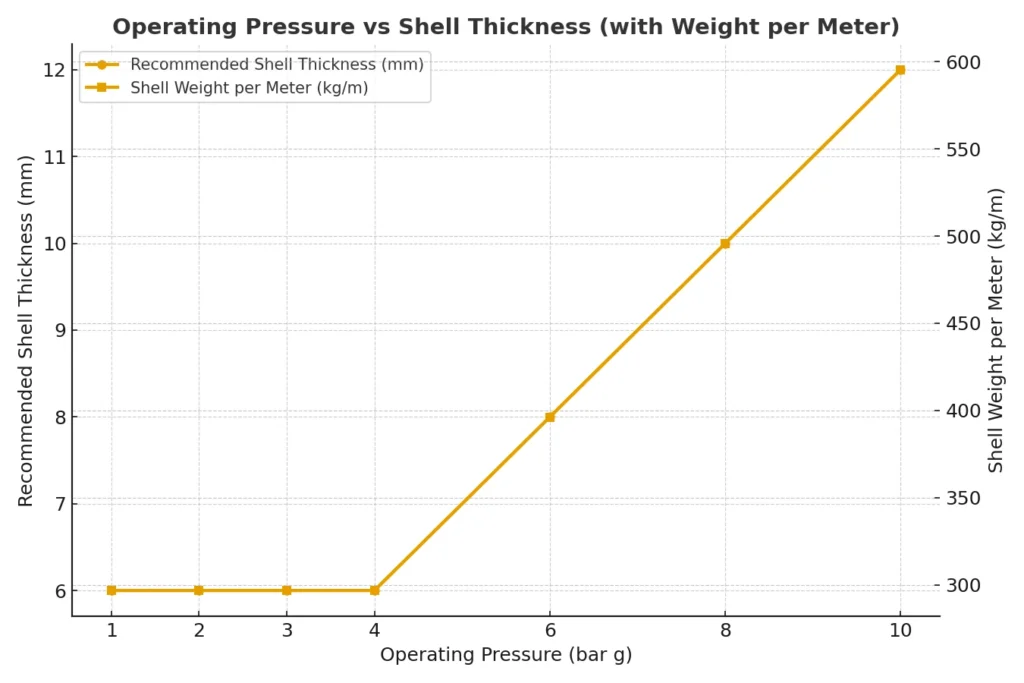

🧪 Operating Pressure vs Shell Thickness (with Weight per Meter)

Shell thickness selection is a critical decision in reactor design because it governs safety, durability, and total installed cost. The chart correlates operating pressure with recommended shell thickness (including corrosion allowance) and shows how thickness impacts shell weight per meter, helping buyers plan for fabrication, lifting, and budget.

💡 Insight & Analysis

For a 2000 mm ID reactor, 6 mm nominal (with 2 mm CA) is adequate up to ~4 bar(g) in this example; above that, step-ups to 8/10/12 mm maintain hoop stress well below S×E.

Notice how weight per meter jumps from ~297 kg/m at 6 mm to 595 kg/m at 12 mm—doubling lift/load requirements and cost.

SV Industries optimizes thickness with proper weld category, NDT level, and corrosion allowance to achieve a safe, economical design—reducing over-design while staying code-compliant.

Buyers benefit from lower material cost, easier handling, and faster fabrication without compromising safety—especially important for chemical reactor manufacturers, industrial reactor suppliers, and end-users across reactor applications.

Applications of Reactor Vessels in Industrial Processes

A reactor vessel is used in industries to carry out chemical reactions, mixing, heating, and cooling under controlled conditions.

It is the core equipment in process industries, ensuring safety, efficiency, and consistent product quality.

| Industry / Sector | Typical Applications |

|---|---|

| Chemical Industry 🧪 | Polymerization, sulphonation, nitration, oxidation, chlorination |

| Pharmaceuticals & Biotechnology 💊 | Formulation, fermentation, crystallization, synthesis reactions |

| Food & Beverage 🍶 | Mixing, blending, pasteurization, cooking, flavor extraction |

| Dyes, Pigments & Paints 🎨 | Dispersion, emulsification, pigment synthesis, resin preparation |

| Oil, Gas & Petrochemicals 🛢️ | Hydrogenation, cracking, catalytic reactions, reforming |

| Water & Wastewater Treatment 💧 | Neutralization, aeration, chemical dosing, sludge treatment |

| Agrochemicals & Fertilizers 🌱 | Pesticide formulation, fertilizer blending, intermediate reactions |

| Cosmetics & Personal Care 💄 | Lotion, shampoo, cream emulsification, essential oil extraction |

| Paper & Pulp 📄 | Pulp cooking, bleaching, chemical treatment of fibers |

| Adhesives & Sealants 🏷️ | Polymerization, resin mixing, heat-sensitive adhesive preparation |

| Batteries & Energy Materials 🔋 | Electrolyte preparation, cathode/anode material processing |

| Textile Processing 👕 | Dye preparation, finishing chemical reactions, auxiliaries production |

Advantages of Choosing SV Industries Reactor Vessels

At SV Industries, we don’t just build reactor vessels — we engineer long-term process solutions. Here are the key advantages that make us a trusted reactor vessel manufacturer in India:

| Advantage | Why It Matters |

|---|---|

| 1. Custom-Engineered Design 🏗️ | Tailored solutions for chemical, pharma, food, and petrochemical processes. |

| 2. Wide Capacity Range ⚖️ | From 100 Liters to 50,000 Liters — suitable for pilot plants to large industries. |

| 3. Material Versatility 🛡️ | MS, SS 304, SS 316/316L, Alloy steels, and glass/PTFE lining for durability. |

| 4. Advanced Agitation Systems 🔄 | Options include Anchor, Pitch Blade Turbine, Rushton, Helical, Paddle impellers. |

| 5. Superior Thermal Control 🌡️ | SS Jacketed Vessels and Limpet Coil Reactors ensure efficient heating & cooling. |

| 6. International Quality Standards ✅ | ASME, DIN, IS, and GMP-compliant design and fabrication. |

| 7. Robust Safety Features 🔒 | Tested with hydro, pneumatic, and NDT methods for leak-proof operation. |

| 8. Long Service Life ⚙️ | High-quality welding, finishing, and corrosion resistance reduce downtime. |

| 9. Automation Compatibility 📊 | PLC/DCS integration with temperature, pressure, and RPM sensors. |

| 10. Hygienic Finishing ✨ | Mirror-polish surface finishes for pharma & food-grade compliance. |

| 11. End-to-End Support 🤝 | Design → Fabrication → Installation → After-sales service. |

| 12. Proven Industry Trust 🌍 | Strong track record as a leading agitator and reactor manufacturer in India. |

📌 Why Buyers Prefer SV Industries

Saves cost with energy-efficient designs.

Ensures safe & reliable operations even under extreme conditions.

Enhances process yields and product quality.

Backed by decades of industry expertise.

Choose SV Industries for reactor vessels that combine engineering precision, safety, and unmatched durability. Contact us today to get your project started.

Comparison: Reactor Vessel vs Other Process Equipment

Many industries confuse reactor vessels with other process equipment like storage tanks or mixers. While they may look similar, their functionality, design, and purpose are very different.

Here’s a quick comparison:

| Feature | Reactor Vessel | Storage Tank | Industrial Mixer | Fermenter | Heat Exchanger |

|---|---|---|---|---|---|

| Primary Function | Carries out controlled chemical reactions with heat, pressure, and agitation | Stores raw materials, intermediates, or finished products | Mixes liquids/solids without chemical reaction control | Biological fermentation under sterile conditions | Transfers heat between two fluids without mixing |

| Temperature Control | Yes (jacket/limpet coil for heating & cooling) | No (only insulation if required) | Limited (depends on mixer vessel design) | Yes (precise thermal regulation for microorganisms) | Yes (primary function is heat exchange) |

| Pressure Handling | Vacuum up to 60 bar | Mostly atmospheric, sometimes low pressure | Generally atmospheric | Low to medium pressure | Low to high pressure (depending on design) |

| Agitation | Advanced impellers (anchor, turbine, helical, paddle) | Not applicable | Main function: mixing (basic impellers) | Agitation with sterile sparging | Not applicable |

| Applications | Chemical synthesis, pharma, petrochemicals, dyes, food | Storage of chemicals, solvents, intermediates | Paints, coatings, slurry mixing, emulsions | Pharmaceutical & biotech fermentation | Heating/cooling in process plants |

| Process Control | Fully automated with sensors (temp, pressure, RPM) | Minimal (level indicators only) | Basic control (speed, time) | Strict aseptic control | Temperature & flow control |

| Cost Level | Higher (due to complexity & customization) | Lower | Moderate | High (due to sterile design) | Moderate to High |

📌 Key Takeaway for Buyers

A reactor vessel is not just a storage or mixing device — it is the heart of chemical and pharmaceutical plants where actual reactions occur.

Other equipment like storage tanks, mixers, fermenters, and heat exchangers play supporting roles but cannot replace a reactor vessel in controlled reaction processes.

Looking for a reactor vessel tailored to your process instead of a standard mixer or tank? Contact SV Industries for expert consultation and customized solutions.

Maintenance, Safety, and Operational Guidelines for Reactor Vessels

Proper maintenance and safe operation of reactor vessels are essential to ensure long service life, consistent performance, and accident-free plant operations. As a trusted reactor vessel manufacturer in India, SV Industries provides clear guidelines that help industries maximize reliability and efficiency.

🧹 Regular Maintenance Practices

Cleaning & Inspection: After each production cycle, clean the vessel to remove residues and prevent contamination.

Surface Protection: For SS 304/316 vessels, maintain surface polishing to avoid pitting or corrosion.

Agitator Care: Inspect agitators and impellers regularly for wear, alignment, and vibration.

Heating & Cooling Systems: Flush SS jacketed vessels and limpet coil reactors to prevent scaling and blockages.

Seal & Gasket Replacement: Monitor seals (mechanical/lip stuffing box) and replace them at scheduled intervals.

Testing: Conduct periodic hydro and pneumatic testing to ensure leak-proof safety.

⚠️ Safety Guidelines

Pressure & Temperature Limits: Never exceed the rated design range (Vacuum to 60 bar, -20°C to 300°C).

Instrumentation Monitoring: Use automation sensors (temperature, RPM, pressure) for continuous tracking.

Emergency Valves: Ensure pressure relief valves and safety vents are tested regularly.

Operator Training: Only trained personnel should handle reactor vessel operation.

Safe Charging of Materials: Add raw materials slowly to prevent sudden reactions or foaming.

Hazardous Chemicals: For corrosive or volatile reactions, use lined vessels (glass/PTFE/rubber) to enhance safety.

⚙️ Operational Best Practices

Start agitation gradually to avoid sudden mechanical stress.

Pre-check nozzles, manways, and instrumentation ports before starting any batch.

Maintain a steady heating/cooling rate to prevent thermal shock.

Optimize agitation speed according to the type of impeller (anchor, helical, rushton turbine, etc.).

Keep proper logbooks of cleaning, inspection, and test records for compliance.

Ensure maximum safety and performance of your reactor vessels with SV Industries’ proven engineering and maintenance expertise.

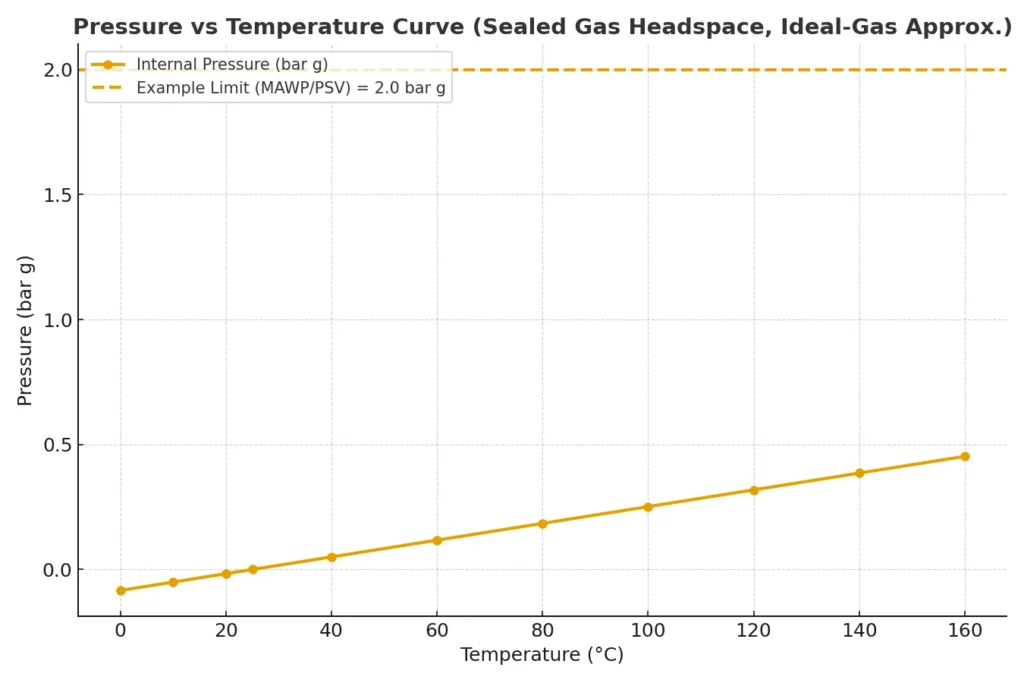

🌡️ Pressure vs Temperature Curve (Sealed Gas Headspace)

In sealed reactors with gas headspace, internal pressure rises with temperature. Understanding this Pressure–Temperature (P–T) relationship is crucial for safe reactor design, correct PSV/rupture disk sizing, and operating envelopes. The chart shows how a system sealed at 1 bar abs, 25 °C develops pressure as temperature increases.

💡 Insight & Analysis

Cooling below 25 °C creates slight vacuum (negative bar g), which can affect thin-wall vessels and gaskets.

Heating to 100 °C raises pressure to ~0.25 bar g; by 160 °C, ~0.45 bar g in this example.

The example limit line helps visualize margin to MAWP/PSV; actual limits must be per ASME, PED or applicable code with full load cases.

SV Industries calibrates design temperature/pressure, headspace sizing, and pressure relief to keep operations safe and efficient—supporting buyers across Industrial Chemical Reactor projects, reactor design, and reactor applications.

Key Considerations When Choosing Reactor Vessel Manufacturer & Supplier

Choosing the right reactor vessel manufacturer in India is not just about price — it directly impacts plant safety, product quality, and long-term operational costs. Buyers should carefully evaluate technical capabilities, certifications, and after-sales support before finalizing any supplier.

📊 Important Factors to Evaluate

| Consideration | Why It Matters |

|---|---|

| 1. Engineering Expertise 🏗️ | Manufacturers with proven design knowledge ensure vessels meet ASME/DIN/IS standards and handle complex reactor applications. |

| 2. Customization Options ⚙️ | Every process is unique. Check if the supplier can offer vessels with tailored capacity, pressure rating, and [agitator](https://sv-industries.com/agitator/) options. |

| 3. Material of Construction 🛡️ | From MS to SS 304, SS 316, and lined reactors, the right MOC ensures durability against corrosion, heat, and chemicals. |

| 4. Agitation & Mixing Technology 🔄 | Efficient mixing is vital. Confirm if they provide impeller options such as Anchor, Pitch Blade, Helical, or Rushton for different reactor designs. |

| 5. Thermal Control 🌡️ | Check for availability of [SS Jacketed Vessels](https://sv-industries.com/ss-jacketed-vessel/) or [Limpet Coil Reactors](https://sv-industries.com/limpet-coil-reactor-vessel/) for heating and cooling efficiency. |

| 6. Quality Certifications ✅ | Trusted suppliers provide ASME, DIN, IS, and GMP-compliant equipment, ensuring global acceptance. |

| 7. Safety Standards 🔒 | Hydro/pneumatic testing, relief valves, and robust fabrication are critical for plant and operator safety. |

| 8. Industry Experience 📈 | Suppliers with diverse installations across chemical, pharma, food, and petrochemical sectors provide proven reliability. |

| 9. After-Sales Support 🤝 | Regular maintenance, spare parts availability, and service response increase vessel lifespan and reduce downtime. |

| 10. Value for Investment 💰 | Lowest cost is not always best. Evaluate long-term value, durability, and operational savings. |

📌 Why Buyers Trust SV Industries

Strong presence as a leading industrial reactor supplier.

Expertise in multiple reactor applications including chemical process reactors and industrial chemical reactors.

Decades of hands-on fabrication and installation experience.

End-to-end support: Design → Fabrication → Testing → Installation → Service.

Choose SV Industries as your trusted reactor vessel partner and ensure unmatched safety, quality, and process efficiency. Contact us today for tailored solutions.

SV Industries – Leading Reactor Vessel Manufacturer in India

When it comes to reactor vessel manufacturing in India, SV Industries stands out as a trusted name for quality, reliability, and innovation. With decades of engineering expertise, advanced fabrication facilities, and strict adherence to international codes, we are recognized as a leading industrial reactor supplier for chemical, pharmaceutical, petrochemical, food, and specialty industries.

⚙️ Why SV Industries is the Preferred Choice

Proven Expertise: Years of experience in reactor design and process equipment manufacturing.

Wide Product Range: From SS Jacketed Vessels and Limpet Coil Reactors to customized Chemical Process Reactors.

Advanced Agitation Systems: Offering Anchor Impellers, Pitch Blade Turbines, Helical Impellers, and Rushton Turbines for maximum efficiency.

Material Excellence: Vessels fabricated in MS, SS 304, SS 316, SS 316L, Alloy Steels, and lined designs for corrosive environments.

Compliance & Quality: Built as per ASME, DIN, IS, and GMP standards, ensuring safety and durability.

Pan-India Reach: Trusted by industries across Gujarat, Maharashtra, Tamil Nadu, Andhra Pradesh, West Bengal, and beyond.

🌍 Our Market Leadership

Strong reputation as the best agitator manufacturer in India and a reliable partner for complete process equipment solutions.

Continuous innovation in reactor applications like polymerization, hydrogenation, crystallization, and blending.

Supported by a dedicated team delivering design → fabrication → testing → installation → after-sales support.

“Partner with SV Industries – India’s leading reactor vessel manufacturer – and take your process efficiency, safety, and quality to the next level. Contact us today for a consultation.”

Reactor Vessel – Technical FAQs & Buyer’s Guide

What is the maximum pressure a reactor vessel can handle?

A reactor vessel can handle pressures from full vacuum up to 60 bar, depending on design and material.

Which material is best for a reactor vessel – SS 304 or SS 316?

SS 316 is preferred over SS 304 when the process involves acids, chlorides, or highly corrosive chemicals.

How do reactor vessels maintain temperature during chemical reactions?

Reactor vessels use jackets or limpet coils for heating and cooling to maintain controlled temperatures.

What types of agitators are used in reactor vessels?

Common agitators include Anchor, Pitch Blade, Rushton Turbine, Paddle, and Helical Impellers.

What is the difference between a reactor vessel and a storage tank?

A reactor vessel is designed for chemical reactions under controlled pressure and temperature, while a storage tank is only for holding materials.

What are the testing methods for reactor vessel safety?

Reactor vessels are tested using hydro tests, pneumatic tests, and non-destructive testing (NDT) methods.

Can reactor vessels be automated with PLC/DCS systems?

Yes, modern reactor vessels are fully compatible with PLC/DCS automation for monitoring and control.

How long is the service life of a reactor vessel?

A well-maintained reactor vessel typically lasts 15–25 years, depending on usage and material.

How can I get a reactor vessel from SV Industries?

You can contact us directly via our website or customer support for inquiries, quotes, and order placements. We provide delivery and installation services across various regions.