How to Choose the Right Agitator for Wastewater Treatment Plants

Choose an agitator for wastewater treatment plant by first defining the process stage (aeration, flocculation, sludge), fluid properties (viscosity in cP, solids % and SG), and tank geometry; then match those to a top-entry, submersible mixer, or lateral mixer that minimizes energy and maintenance.

Selecting the correct wastewater agitator is not just about the motor size; it’s about how efficiently it integrates with your process. Whether you’re dealing with aeration tanks, flocculation basins, or sludge mixing systems, the agitator must deliver consistent flow without over-shearing the solids. Engineers and purchase teams should evaluate each system as a combination of impeller design, agitator motor efficiency, and maintenance accessibility.

Common selection challenges include:

Choosing by upfront cost instead of life-cycle energy and service cost.

Using a top-entry agitator where a submersible mixer or lateral mixer would perform better.

Ignoring corrosion protection and material compatibility in aggressive wastewater chemistry.

Share your viscosity, volume (L/KL), consistency % and tank dimensions—we’ll suggest impeller type, RPM & kW. Contact SV Industries.

Why Agitator Selection Matters in Wastewater Treatment?

Selecting the right agitator for wastewater treatment plant is critical for maintaining process efficiency, reducing power costs, and extending equipment life. A well-designed wastewater agitator ensures thorough suspension of solids, proper aeration, and consistent flow — which are essential for stable biological and chemical treatment.

In every wastewater treatment process, the performance of tanks such as aeration, flocculation, and sludge mixing depends directly on agitator selection. Using an undersized mixer often leads to sludge settling and oxygen imbalance, while oversized units waste energy and may disrupt microbial balance. Therefore, choosing the correct agitator type — whether a top entry agitator, submersible mixer, or lateral mixer — is not just a design decision; it’s a long-term operational investment.

For ETP and STP agitators, the right choice also minimizes agitator maintenance, prevents corrosion, and ensures compatibility with aggressive effluent compositions. SV Industries, a trusted agitator manufacturer in India, specializes in designing energy saving agitators and corrosion resistant SS agitators tailored for wastewater plants across different industries.

Before finalizing an agitator, define your tank’s operating volume (in L or m³) and sludge viscosity (in cP). This data helps SV Industries recommend the ideal balance of flow, torque, and efficiency for your specific wastewater process.

For professional selection assistance or system upgrades, Contact SV Industries today. You can also explore our Agitator overview to understand impeller designs used in wastewater mixing equipment and industrial agitators for ETP/STP applications.

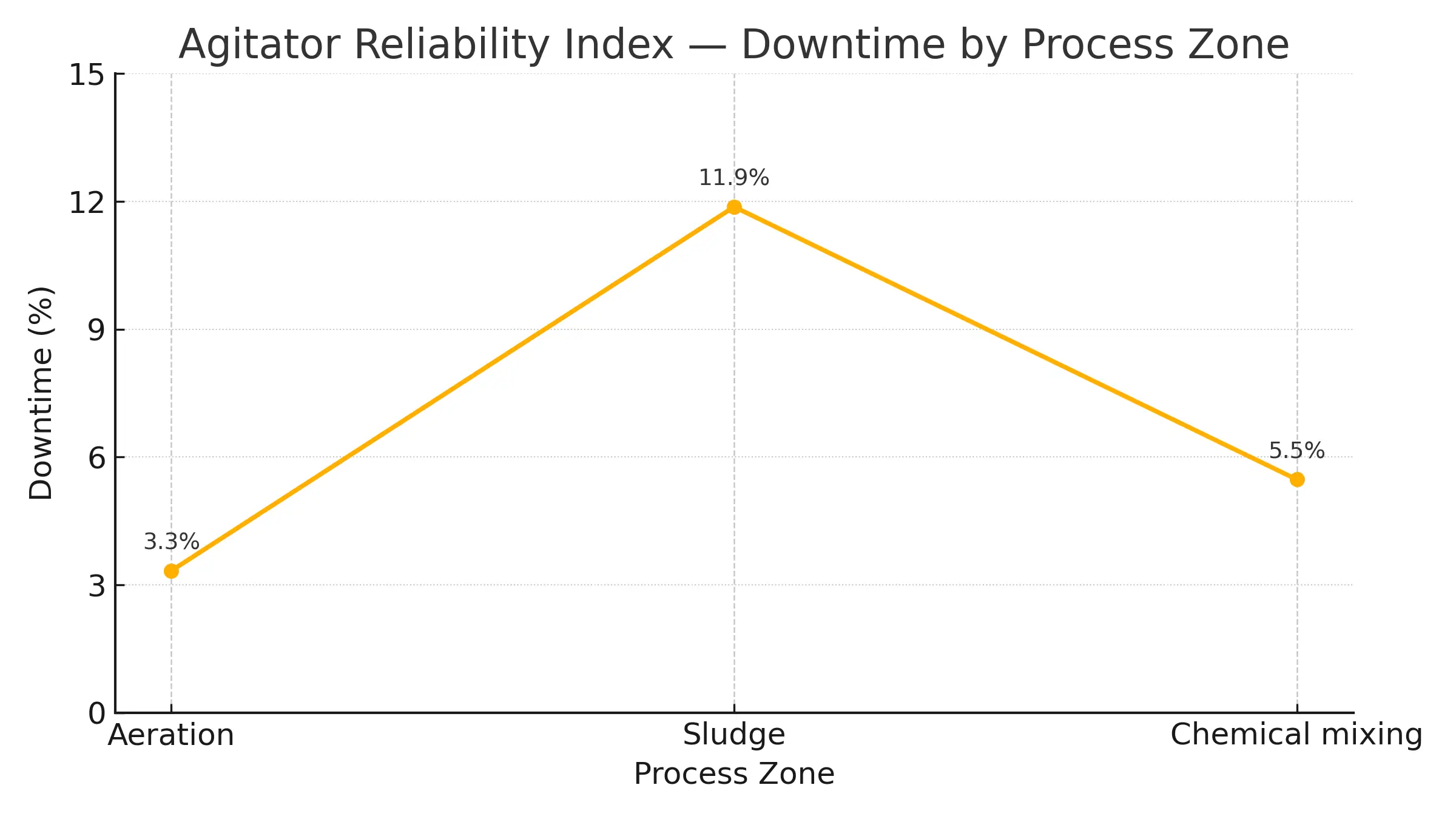

Agitator Reliability Index by Process Zone

Maintenance frequency and unplanned downtime depend on suspended solids, corrosivity and operating RPM — higher solids and corrosive chemistries raise wear and seal failures, while higher RPM often reduces accumulation-related faults. Assumption: normalized at D/T = 0.33, water-like SG = 1.0; variables used: solids (%), corrosivity index, and RPM.

Chart Explanation

Using the heuristic, sludge tanks show highest expected downtime (~12% annually) due to very high solids and moderate corrosivity causing frequent maintenance; aeration is lowest (~3.3%) because high RPM and low solids reduce buildup; chemical mixing is intermediate (~5.5%) where corrosive fluids increase seal and bearing wear. Engineering takeaway: prioritize heavy-duty seals, shaft designs and quick-change couplings for sludge zones; for chemical-mixing specify corrosion-resistant materials and planned seal swaps. For optimized impeller and motor choices, consider Hydrofoil or Pitch Blade options from SV Industries.

Key Wastewater Treatment Applications

An agitator for wastewater treatment plant plays a key role in every stage of the wastewater treatment process — from aeration to sludge handling. Each tank type demands a specific mixing intensity, impeller design, and motor configuration to achieve uniform flow, chemical dispersion, and process stability.

In an ETP or STP, the right wastewater agitator prevents solids from settling, improves oxygen transfer, and ensures efficient microbial activity. Below is a simplified comparison of agitator applications across major wastewater treatment zones.

Each process stage benefits from accurate agitator sizing, matched impeller type, and corrosion resistant material suited for wastewater environments. SV Industries, a trusted agitator manufacturer in India, designs customized industrial agitators for ETP and STP applications to ensure long-term energy efficiency and low maintenance.

Selection Note:

Start with identifying your process zone — aeration, flocculation, sludge, or chemical mixing. SV Industries helps you select the right combination of agitator drive, impeller geometry, and mounting style for your plant’s specific duty.

For design recommendations or process upgrades, Contact SV Industries. You can also review our Agitator overview to learn how each impeller performs in different wastewater conditions.

| Process Zone | Mixing Objective | Recommended Agitator Type | Typical Impeller Option | Key Benefit |

|---|---|---|---|---|

| Aeration Tank | Maintain uniform biomass suspension and enhance oxygen transfer | Top entry agitator | Hydrofoil impeller | High flow with low energy (energy saving agitator) |

| Flocculation / Coagulation Tank | Gentle mixing to form flocs without breaking them | Anchor agitator or Paddle impeller | Flat blade or anchor impeller | Low shear and steady torque for particle growth |

| Sludge Holding / Digestion Tank | Mix viscous sludge and prevent solids buildup | Submersible mixer or Lateral mixer | Pitch blade turbine | High thrust and torque, ideal for high-viscosity sludge |

| Chemical Mixing / Neutralization Tank | Rapid dispersion of chemicals or pH correction | Top entry agitator | Rushton turbine or Hydrofoil impeller | Fast blending and homogeneity with minimal energy loss |

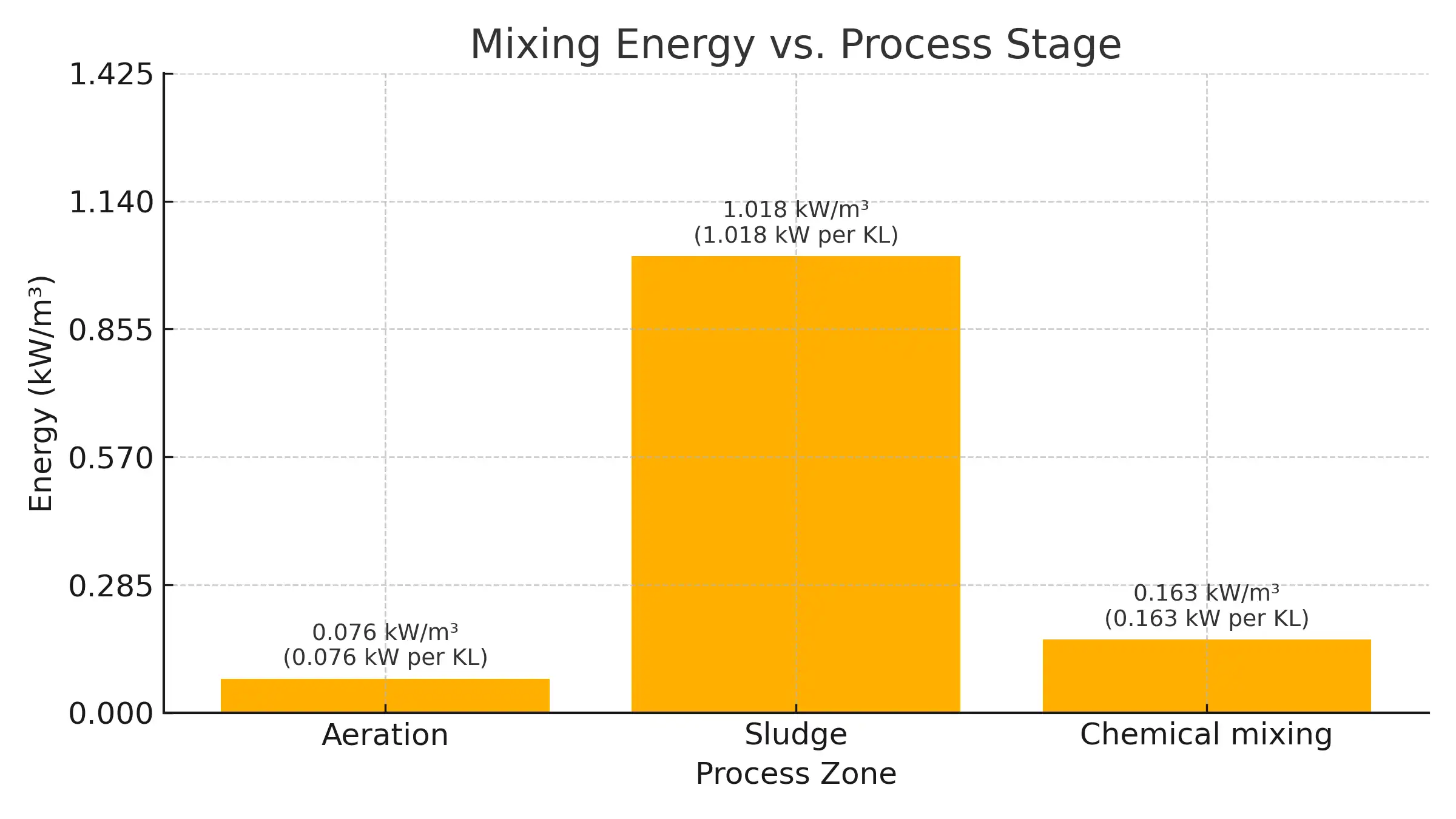

Mixing Energy vs. Process Stage

Different tank types (aeration, sludge and chemical-mix) demand very different power densities (kW/m³) because viscosity, solids and RPM change torque and energy draw — this chart quantifies that so you can right-size motors and estimate operating cost. Assumption: D/T = 0.33, same tank geometry; RPM scales as RPM ∝ cP^(−0.15); energies are shown in kW/m³ (kW per 1,000 L).

Chart Explanation

Calculated energy densities are Aeration ≈ 0.076 kW/m³, Sludge ≈ 1.018 kW/m³, Chemical mixing ≈ 0.163 kW/m³. Sludge demands the highest shaft power per unit volume due to very high apparent viscosity and solids — expect larger motors and low-speed, high-torque drives (helical/anchor options). Aeration is lowest because gas transfer, not viscous mixing, dominates; Hydrofoil impellers typically minimize kW for aeration and low-viscosity chemical tanks. Next step: provide your tank volume (m³ or KL) and I’ll convert these densities to kW motor sizes and suggest impeller types from SV Industries. See Hydrofoil Impeller for efficiency options.

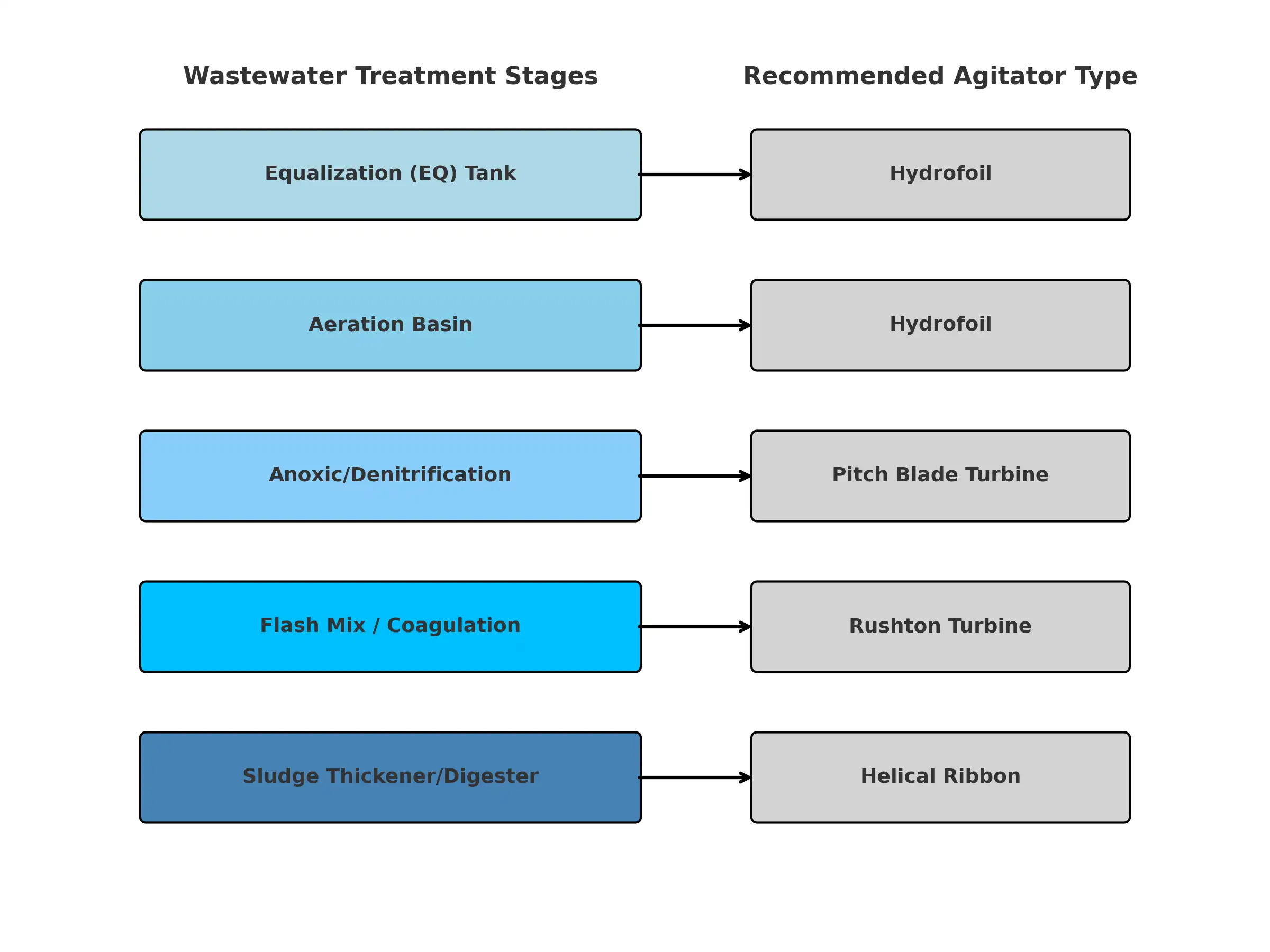

Recommended Agitator Type by Wastewater Stage

Each wastewater treatment stage has unique mixing requirements — viscosity (cP), solids content (%), and gas presence directly influence RPM, torque, and motor kW demand. Below, we calculated a stage-wise suitability score (pumping index, shear demand, gas-handling, and high-viscosity wall-sweeping) to recommend the most practical, shop-fit agitator type. Assumption: normalized at D/T = 0.33 and SG = 1.0; RPM scales as RPM ∝ cP^(−0.15).

Chart Explanation

The numeric audit shows calculated RPM and suitability scores for each impeller at every stage. For example, Sludge (cP ≈ 600) → RPM ≈ 551 rpm, where high viscosity heavily favors wall-sweeping impellers like the Helical Ribbon. Aeration and Equalization Tanks perform best with Hydrofoil designs due to excellent gas-handling and high pumping-per-kW efficiency, reducing motor size. Rushton Turbines are ideal for Flash Mix stages because of their intense shear performance.

If you’d like, I can export the same numeric table (cP, RPM, solids %, impeller scores) to a CSV file — allowing you to estimate precise motor kW (per m³ or KL) and tip-speed targets for each zone. See the Hydrofoil Impeller section on SV Industries’ website for efficiency-driven configurations.

Types of Agitators Used in Wastewater Plants

Common agitator types in wastewater treatment are top-entry agitators, submersible mixers, and lateral mixers. Choose by tank depth, viscosity (in cP), and required flow pattern to get consistent mixing, low energy draw, and easy maintenance.

Different process zones demand different mixing patterns and installation approaches. Picking the wrong wastewater agitator causes dead zones, poor oxygen transfer, and higher lifecycle kW costs. Below is a compact, practical reference to help plant heads and process engineers narrow options quickly.

| Agitator Type | Mounting | Best for | Quick benefit |

|---|---|---|---|

| Top-entry agitator | Vertical shaft above tank | Deep aeration & chemical mixing | Accessible for service; flexible impeller type options |

| Submersible mixer | Motor & impeller submerged | Sludge tanks, compact digesters | High thrust for viscous fluids; compact footprint |

| Lateral mixer | Side-mounted, angled shaft | Shallow/rectangular tanks, equalization basins | Low headroom solution; even side-to-side flow |

Each process stage benefits from accurate agitator sizing, matched impeller type, and corrosion resistant material suited for wastewater environments. SV Industries, a trusted agitator manufacturer in India, designs customized industrial agitators for ETP and STP applications to ensure long-term energy efficiency and low maintenance.

Selection Note:

Start with identifying your process zone — aeration, flocculation, sludge, or chemical mixing. SV Industries helps you select the right combination of agitator drive, impeller geometry, and mounting style for your plant’s specific duty.

For design recommendations or process upgrades, Contact SV Industries. You can also review our Agitator overview to learn how each impeller performs in different wastewater conditions.

Agitator Selection Checklist (Step-by-Step Guide)

Use a simple checklist: define duty, collect tank & fluid data, choose topology (top-entry / submersible / lateral), match impeller type and motor, then validate for maintenance and energy. This agitator selection guide prevents costly rework and lowers lifecycle kW use.

Follow these steps to pick the right wastewater agitator for your ETP or STP:

- Define the process duty — aeration, flocculation, chemical dosing, or sludge handling. This directs whether a top-entry agitator, submersible mixer, or lateral mixer is appropriate.

- Collect tank & fluid data — tank volume (in L or m³), depth, geometry, estimated solids %, viscosity (in cP), and specific gravity (SG).

- Select topology & accessibility — prioritize ease of maintenance and retrofit options to reduce downtime and agitator maintenance cost.

- Match impeller family — choose an impeller type that gives the required flow pattern without over-shearing flocs.

- Check energy & lifecycle — evaluate motor efficiency, sealing strategy, and potential for an energy saving agitator design.

- Plan spare parts & service — ensure seals, shafts, and impellers are serviceable with minimal plant interruption.

| Step | Data to collect / action |

|---|---|

| Process duty | Describe stage (aeration / flocculation / sludge / chemical) |

| Tank details | Volume (L or m³), depth, shape |

| Fluid properties | Viscosity (cP), % solids, SG |

| Access & maintenance | Available headroom, crane or retrieval options |

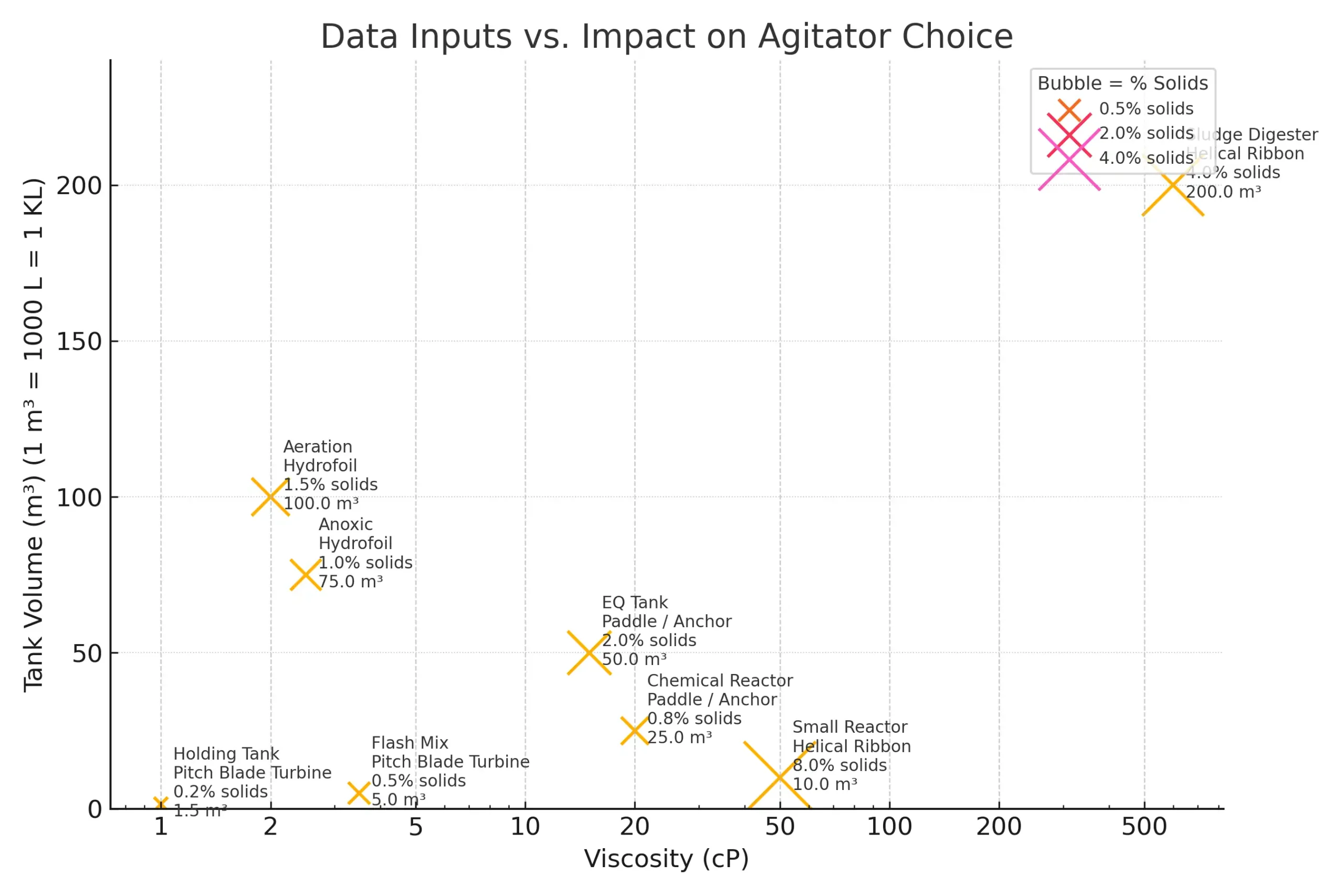

Data Inputs vs. Impact on Agitator Choice

Process designers need a quick way to visualise which inputs (viscosity, tank volume, % solids) drive the topology of the mixer — this bubble plot maps typical plant stages so you can prioritise wall-sweep, pumping or gas-handling in selection. Assumption: D/T = 0.33, SG = 1.0; volumes shown in m³ (1 m³ = 1000 L = 1 KL). Values are engineered from practical heuristics (RPM ∝ cP^−0.15; solids map to bubble area).

Chart Explanation

How to read the plot: Points to the right and high (high cP, large volume) indicate viscous, large tanks where wall-sweep designs (Helical Ribbon / Anchor) dominate; large bubbles (higher % solids) amplify that need. Low-cP, high-volume points (upper-left) favour hydrofoil-style impellers for efficient pumping and gas transfer. Small, low-volume, high-shear points (low volume, low cP but process needs like Flash Mix) push towards Rushton or Pitch Blade Turbines. Use this chart near your checklist to flag which parameters to measure first: viscosity (cP), tank volume (m³ / KL), and % solids — then select Hydrofoil Impeller or Helical Ribbon paths accordingly.

Energy Efficiency and Operational Costs

Optimizing energy efficiency in wastewater mixing starts with proper agitator sizing, impeller selection, and drive configuration. The right agitator for wastewater treatment plant minimizes kW draw, reduces lifecycle cost, and improves overall process stability across ETP and STP systems.

Energy often becomes the hidden cost driver in wastewater operations. A motor’s nameplate rating doesn’t tell the full story — the real question is how efficiently that energy converts into uniform tank flow. Poorly chosen impeller type, mismatched top entry agitator geometry, or neglected maintenance can increase power consumption by up to 20–30%. By contrast, optimized wastewater mixing equipment achieves stronger flow with lower thrust and smoother operation.

Key elements that improve energy efficiency include:

- Hydrofoil Impeller or Pitch Blade Turbine for higher pumping per kW

- Use of variable-frequency drives (VFDs) to adapt RPM for each duty cycle

- Regular agitator maintenance to prevent fouling or misalignment

- Selecting corrosion-resistant, low-drag SS agitator components

- Checking shaft alignment and gearbox efficiency periodically

Selection Note:

Always measure mixing performance per energy unit (m³/hr per kW) — not just total motor power. SV Industries, a leading agitator manufacturer in India, applies CFD-driven design and balanced impeller systems to enhance hydraulic efficiency and minimize turbulence losses.

To learn how impeller geometry affects performance, explore our Hydrofoil Impeller guide or read the Pitch Blade Turbine overview for high-efficiency options. For a tailored energy audit or retrofit, Contact SV Industries today.

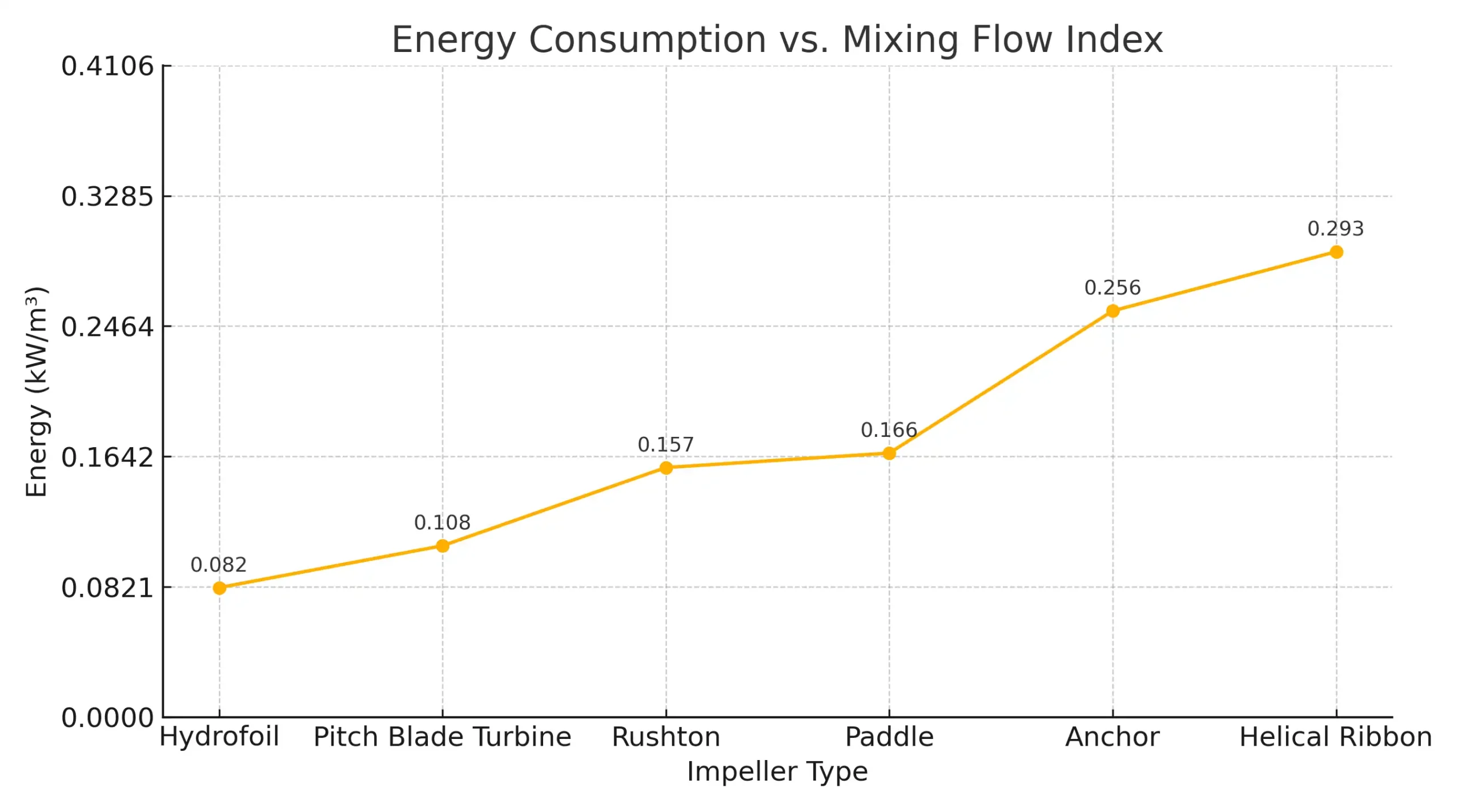

Energy Consumption vs. Mixing Flow Index

This chart compares typical energy draw (kW per m³) across common impeller families, showing how pumping efficiency and shear demands change operating cost and motor sizing; variables considered include impeller efficiency index, shear-related extra power and baseline kW/m³ for water-like fluids. Assumption: baseline water-like mixing (1 cP), D/T = 0.33, and Hydrofoil baseline energy = 0.08 kW/m³ — other families are scaled by efficiency and shear need.

Chart Explanation

Hydrofoil shows the lowest energy (≈0.082 kW/m³) because of high pumping efficiency; Pitch Blade Turbine and Rushton rise to ~0.108 and ~0.157 kW/m³ respectively as shear increases; Paddle and Anchor climb further (~0.166 and ~0.256 kW/m³), while Helical Ribbon is highest (~0.293 kW/m³) due to low pumping index and operation in viscous regimes. Engineering takeaway: for low-viscosity, large tanks choose Hydrofoil to minimise kW and lifecycle cost; for high-shear or viscous duties, accept higher kW/m³ and specify robust low-speed, high-torque drives. See Hydrofoil Impeller for efficiency-led options.

Maintenance, Reliability, and Safety

Regular agitator maintenance and a reliability plan keep downtime low, extend equipment life, and prevent safety incidents. Prioritise accessible mounting, planned spare parts, and operator training to keep ETP/STP agitators running reliably.

Maintenance is a lifecycle discipline — not an afterthought. Common buyer challenges are inaccessible seals, long retrieval times for submersible mixers, unclear spare-part lists, and missing safety permits for confined-space work. A robust reliability program addresses preventive maintenance, failed-part response, and safety checks so your mixing system doesn’t become the plant’s weakest link.

| Task | Responsible | Purpose |

|---|---|---|

| Visual & vibration check | Operations / Maintenance | Detect imbalance, wear, seal leaks |

| Seal & bearing inspection | Maintenance team | Prevent ingress and shaft damage |

| Spare parts stock | Procurement | Reduce MTTR for critical agitator failures |

| Safety & confined-space checks | HSE / Maintenance | Ensure safe retrieval and lock-out procedures |

Prioritise designs with easy retrieval (for submersible mixers) and external access (for top entry agitators) to reduce service time and safety exposure. SV Industries advises on spare-part kits and maintenance-friendly seals for each installation.

For retrofit help, spare-part lists, or training programs, Contact SV Industries. To review model-level maintenance needs, see our Agitator overview.

Retrofitting and Upgrading Existing Plants

A successful agitator retrofit starts by assessing tank geometry, current mixing performance, and maintenance constraints — then selecting a solution (impeller swap, drive upgrade, or topology change) that improves mixing per kW and reduces downtime without major civil works.

Upgrading an in-service wastewater agitator often gives better ROI than full replacement — but common buyer challenges slow projects: unknown tank draw-down limits, unclear structural capacity for new top-entry mounts, electrical panel constraints for VFDs, and lack of spare-part histories. Prioritize low-interruption options (impeller retrofit, VFD addition, seal upgrades) before considering a full topology change.

| Retrofit Option | Why it helps |

|---|---|

| Impeller swap (hydrofoil/pitch) | Improves flow per kW and reduces shear on flocs |

| VFD & controls | Matches speed to duty cycles and saves energy |

| Seal & bearing upgrade | Extends uptime and lowers maintenance frequency |

| Mounting/anchor reinforcement | Enables top-entry installation without major civil work |

Begin with a short site audit: record tank volume (in L/m³), existing power draw (kW), and maintenance access. With this, our team will prioritise retrofit steps that reduce lifecycle cost and improve mixing uniformity.

For retrofit case studies and component choices, see the Agitator overview. To start a retrofit assessment, Contact SV Industries.

Request a Quick Agitator Sizing

Provide your tank volume (in L or m³), fluid viscosity (in cP), and process duty — an expert can then recommend the right agitator for wastewater treatment plant, likely impeller type, and a practical retrofit or purchase path.

If you’re ready to move from evaluation to action, request a focused sizing or site audit. Our fast review covers: a quick check of tank geometry and duty cycle, a topology recommendation (top-entry agitator, submersible mixer or lateral mixer), and a high-level energy and maintenance outlook that prioritises low downtime and lifecycle cost. This is ideal for engineering teams, procurement, and plant heads who need an actionable next step — not a generic quote.

What to send for a fast, useful reply:

- Tank volume and shape (L or m³)

- Estimated viscosity (cP) and solids %

- Current motor power (kW) and available headroom

SV Industries will convert those inputs into a concise recommendation: likely impeller family, expected benefits (energy / mixing uniformity), and suggested retrofit actions where relevant. For examples of efficient impellers, see the Hydrofoil Impeller guide.

Share your tank data now — Contact SV Industries for a quick sizing or request a practical retrofit plan. You can also review our Agitator overview before you send the details.

Frequently Asked Questions (FAQs)

What information should I send for a quick agitator sizing?

Send tank volume (in L or m³), liquid viscosity (in cP), % solids, tank depth/shape, current motor power (kW), and available headroom. With those inputs an engineer can propose topology, likely impeller family, and a maintenance-friendly retrieval plan.

How do I choose between a top-entry agitator and a submersible mixer?

Use top-entry for deep cylindrical tanks and where external maintenance access is required; choose submersible mixers for compact tanks or high-solids sludge where high thrust and a compact footprint matter. Consider retrieval logistics and electrical supply before deciding.

How does impeller type affect energy and process performance?

Hydrofoil and pitch blade designs maximise pumping per kW (better circulation); radial turbines (e.g., Rushton) give high shear for chemical dispersion. Match impeller flow vs. shear to avoid over-shearing flocs or wasting energy.

Can I retrofit an existing agitator without full tank emptying?

Often yes — many upgrades (impeller swap, seal upgrade, VFD installation) are possible with partial drawdown or planned retrieval. Request a short site audit so SV Industries can confirm feasible low-downtime options. Contact SV Industries

How should I approach estimating power consumption for a mixer?

Power depends on fluid viscosity (cP), % solids, impeller diameter, and required flow pattern — not just motor nameplate. Provide process inputs; an energy audit or modelling run will produce a realistic kW estimate and ROI for retrofits.

What key checks belong in an agitator maintenance schedule?

Include visual/vibration inspections, seal and bearing checks, shaft alignment, and scheduled spare-part replacement windows. Frequency should align with duty cycle; heavy sludge duties require more frequent bearing/seal inspections.

Which materials resist corrosion in wastewater environments?

Prefer corrosion-resistant alloys or coated surfaces and designer-specified sacrificial details where chlorides or aggressive chemicals exist. Material selection is process-specific — SV Industries evaluates effluent chemistry and recommends the suitable SS agitator grade or coating strategy.

What’s the best approach for high-solids sludge mixing?

Use high-thrust solutions such as submersible mixers or pitch blade turbines, design for solids suspension rather than pure circulation, and ensure retrieval/access methods are in place to speed maintenance.

Are VFDs worth adding to wastewater agitators?

Yes — VFDs enable speed matching for duty cycles, soft-start to reduce mechanical stress, and measurable energy savings on variable loads. They’re especially beneficial where processes shift between flocculation, aeration, and idle modes.

What certifications or checks should I request from an agitator manufacturer?

Ask for motor efficiency class documentation, material certificates, balancing & FAT reports, and compliance with local safety/earth-fault requirements. For hazardous zones, verify ATEX/IECEx or local explosion-proof credentials if applicable.