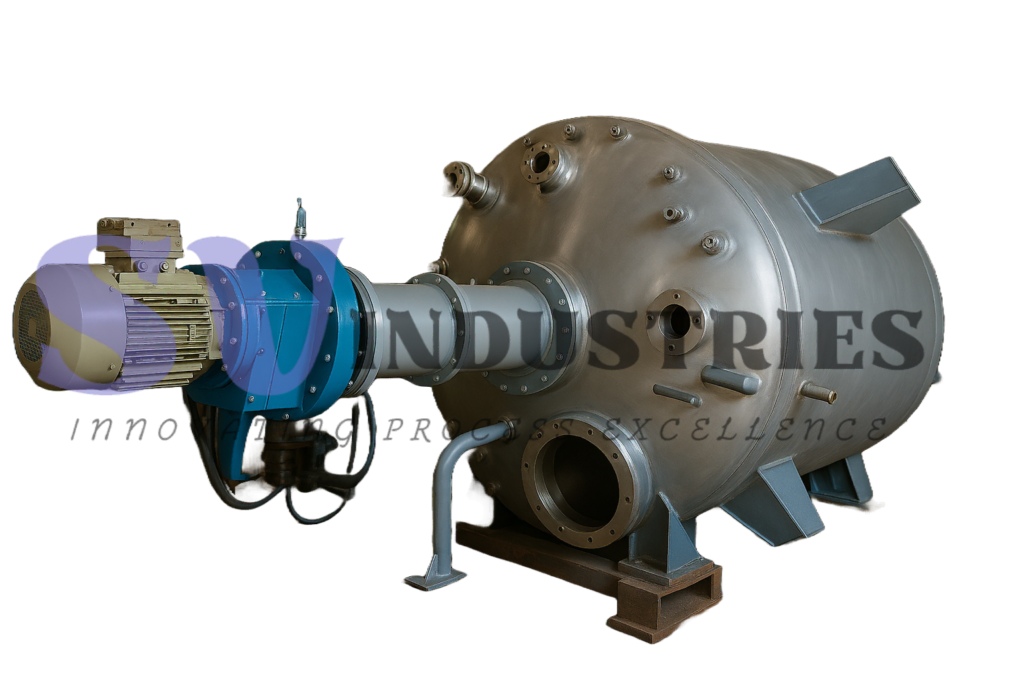

Chemical Process Reactor Manufacturer in India — SV Industries

Custom-engineered reactors for precise mixing, heat transfer, and process control.

From pilot to large-scale production, we design and build industrial reactors that deliver consistent quality, safer operation, and faster batch cycles—backed by engineering support and on-site commissioning.

- Get a Quote → Contact Us

- Talk to an Engineer → Contact Us

- See Installations → Gallery

💡 Why Choose SV Industries

- Process-driven design: Agitation, heat-load, and residence-time engineered for your chemistry.

- Thermal options: Jacketed & Limpet-coil builds for efficient heating/cooling — explore SS Jacketed Vessel and Limpet Coil Reactor Vessel.

- Mixing expertise: Correct impeller selection (Anchor, PBT, Hydrofoil) for viscosity & shear → see our Agitator.

- Built to standards: Material traceability, WPS/PQR, hydrotest, documentation for audits & GMP-ready environments.

- End-to-end support: Design assistance, fabrication, installation, and after-sales across India.

What is a Chemical Process Reactor?

A chemical process reactor is an engineered vessel where raw materials are transformed into desired products under controlled mixing, temperature, pressure, and residence time. It can be batch, semi-batch, or continuous (CSTR/PFR), and typically integrates agitation and heat-transfer features for safe, repeatable performance.

Detailed explanation:

A chemical process reactor combines mechanical design (shell, heads, nozzles) with process control (agitation, heating/cooling, instrumentation) to drive reactions efficiently and safely. In industry, most reactors are built in SS304/SS316 for corrosion resistance and hygiene, sized by required volume and heat load, and rated for the necessary temperature/pressure regime. Thermal management is provided by jackets or limpet coils to add/remove heat during exothermic or endothermic reactions—see our SS Jacketed Vessel and Limpet Coil Reactor Vessel.

Inside the vessel, an agitator ensures uniform mixing, mass transfer, and temperature homogeneity; impeller selection depends on viscosity and shear needs (e.g., Anchor Impeller, Pitch Blade Turbine, Hydrofoil). With the right residence time and process control, the reactor achieves consistent conversion, quality, and cycle time. Learn more on our overview pages: Chemical Process Reactor and Industrial Chemical Reactor.

⚙️ Common Reactor Modes

| Reactor Type | Flow Regime | Best For | Key Advantages |

|---|---|---|---|

| Batch / Semi-batch | Time-bound charges (feeds can be staged) | Multi-product flexibility, scale-up trials | High recipe control, easier cleaning/validation |

| CSTR (Continuous Stirred-Tank) | Steady-state with active mixing | Uniform quality at steady throughput | Good temperature control, simple to operate |

| PFR (Plug-Flow Reactor) | Near plug flow along a tube/pipe | High conversions at long residence times | Compact, efficient for suitable kinetics |

How Does a Chemical Process Reactor Work?

A chemical process reactor converts raw materials into products by controlling mixing, temperature, pressure, and residence time. Agitation ensures uniformity, while a jacket or limpet coil adds/removes heat; instrumentation and automation keep the reaction on-spec and safe.

🔄 Typical Process Flow (Step-by-step)

- Charging: Feed liquids/solids/solvents via nozzles or manway; inerting if required.

- Heating/Cooling: Bring the batch to target temperature using jacket/limpet coil with steam, hot oil, or chilled water—see SS Jacketed Vessel and Limpet Coil Reactor Vessel.

- Agitation & Mass Transfer: Agitator + impeller create bulk flow, shear, and gas–liquid/solid–liquid contact; choose impeller based on viscosity and shear sensitivity—see Agitator.

- Reaction Control: Meter feeds (semi-batch if exothermic), maintain setpoints via PID loops (T, P, RPM).

- Hold / Conversion: Maintain residence time to reach target conversion/yield; sample/validate.

- Discharge & Cleaning: Cool to safe temperature, drain/filter as needed; CIP/SIP or manual cleaning.

🌡️ Heat Transfer & Temperature Control

- Jacketed designs offer uniform coverage and are easy to clean; ideal for multi-product use.

- Limpet coils provide higher allowable pressures/ΔT on the service side and modular repairs.

- Correct U × A (overall coefficient × area) sizing prevents hotspots and reduces cycle time.

Explore: SS Jacketed Vessel · Limpet Coil Reactor Vessel.

⚙️ Core Subsystems (What They Do)

- Agitation system (motor–gearbox–shaft–impeller): Creates uniform mixing, shortens mixing time, improves heat/mass transfer. Choose from Anchor, Pitch Blade Turbine, Hydrofoil, or Helical based on rheology.

- Thermal system (jacket/limpet + utilities): Controls ramp-up, exotherm removal, and cooldown.

- Instrumentation: RTD/thermocouple, pressure gauge/transmitter, level, flow, pH (if applicable).

- Automation: VFD for RPM, temperature/pressure PID, interlocks, alarms, data logging (PLC/HMI).

- Safety: Rupture disk/safety valve, earthing, emergency vents; hydrotest and NDT as per practice.

🌀 Mixing & Impeller Selection

- Low–medium viscosity: Hydrofoil/PBT for high pumping and good heat transfer.

- High viscosity / shear-sensitive: Anchor or helical for bulk circulation with gentle shear.

- Baffles reduce vortexing and improve axial mixing. More options on our Agitator page.

Reactor Designs We Build: Batch, Semi-Batch, CSTR & PFR

From flexible batch systems to high-throughput continuous reactors, we engineer the right chemical process reactor around your kinetics, heat load, and quality targets.

🔁 Core Reactor Configurations

- Batch / Semi-batch: Maximum recipe flexibility, staged feeds for exotherms, ideal for multi-product plants and scale-up trials.

- CSTR (Continuous Stirred-Tank Reactor): Steady-state production with active mixing; excellent temperature control and consistent quality.

- PFR (Plug-Flow / Tubular): Near plug-flow behavior along the length; compact footprint and high conversions for suitable reactions.

Thermal options: Jacketed or limpet-coil designs based on utility pressure/ΔT → see SS Jacketed Vessel and Limpet Coil Reactor Vessel.

Mixing solutions: Impeller selection by viscosity/shear → Agitator, Anchor, Pitch Blade Turbine, Hydrofoil.

📊 Quick Comparison

| Type | Operation Mode | Typical Scale | Heat-Transfer Options | Flow / Agitation | Best For | Key Advantages | Considerations |

|---|---|---|---|---|---|---|---|

| Batch | Time-bound lots | Pilot → Large | Jacket / Limpet | Agitated (Anchor/PBT/Hydrofoil) | Multi-product, variable recipes | High control, easier cleaning/validation | Non-steady throughput |

| Semi-batch | Staged feeding | Pilot → Large | Jacket / Limpet | Agitated | Exothermic/controlled additions | Safer heat removal, better selectivity | Feed strategy complexity |

| CSTR | Continuous | Medium → Large | Jacket / Limpet | Agitated, baffled | Steady quality & throughput | Uniform temperature, simple control | Residence-time distribution (RTD) |

| PFR | Continuous | Small → Very large (modular) | Jacketed tubes / coils | Axial flow (near plug-flow) | High conversion for suitable kinetics | Compact, efficient | Fouling & temperature gradients |

📊 Reaction Time vs Reactor Type (Batch vs CSTR vs PFR)

This chart compares reaction time across Batch, CSTR, and PFR designs for an Industrial Chemical Reactor at a fixed conversion target. It helps buyers understand how reactor design affects cycle time and throughput. For a chemical reactor manufacturer or industrial reactor supplier, this view is vital when matching reactor applications to kinetics and scale-up.

📌 Observations:

At high conversion (e.g., 90%), CSTR requires significantly longer residence time than Batch/PFR for first-order kinetics, because the outlet concentration equals mixed contents. Batch and PFR achieve the same conversion with similar times in this case, making them attractive for faster cycles when steady-state isn’t mandatory. In practice, SV Industries optimizes reactor design with correct U×A and impeller speed to ensure safe temperature control and predictable conversion—improving industrial reactor mixing performance, impeller speed optimization in chemical reactors, and overall reactor efficiency vs agitator RPM.

Materials & Construction for Chemical Process Reactors

Built for corrosion resistance, cleanability, and safe operation. SV Industries engineers each chemical process reactor from the inside out—choosing the right material of construction (MOC), weld procedure, surface finish, and thermal envelope (jacket/limpet) to suit your chemistry and utilities.

🛡️ Materials (MOC) — When to choose what

- SS304: Cost-effective stainless for mildly corrosive media and hygiene needs.

- SS316 / SS316L: Added molybdenum for chlorides/stronger chemicals and better pitting resistance. Preferred for pharma/food contact and CIP.

- MS (Rubber-Lined / FRP-Lined): For highly corrosive acids/solvents that do not attack the lining; economical for large volumes.

- Clad/duplex/special alloys (on request): For aggressive or high-temperature environments where standard grades fall short.

🔩 Fabrication & Finish

- Welding: Qualified WPS/PQR, certified welders; full-penetration welds where required, with controlled heat input.

- Surface finish: Internal Ra as specified (e.g., 0.8–1.6 μm typical), pickling & passivation for stainless; mirror finish on request.

- Nozzles & internals: Baffles, dip pipes, CIP/SIP lances, thermowells—laid out for process access and cleanability.

- Thermal envelope: Jacket for uniform coverage or limpet-coil for higher service pressures/ΔT → see SS Jacketed Vessel and Limpet Coil Reactor Vessel.

🧪 Testing & Documentation

- Hydrotest, leak test, NDT (as applicable), MTC for plates/pipes, and traceability records.

- Protocols aligned to audit needs; IQ/OQ and FAT support available.

📊 Quick Selection Guide

| MOC | Corrosion Resistance (typical) | Cleanability / Finish | Thermal Compatibility | Typical Use Cases |

|---|---|---|---|---|

| SS304 | Mild acids, neutral salts, low chlorides | Good; Ra 0.8–1.6 μm achievable | Steam/hot water/chilled media | General chemicals, food-grade utilities |

| SS316/316L | Better pitting & chloride resistance | Excellent; pharma-grade finishes | Broader temp/window; CIP-friendly | Pharma, dyes/intermediates, fine chem |

| MS (Rubber-Lined) | Excellent where lining is compatible | Lining dictates cleaning method | Limit by lining’s temp/ΔT | Strong acids/solvents (lining-safe) |

| Special Alloys (on request) | For aggressive/oxidizing media | Process-dependent | High temp/pressure envelopes | Challenging chemistries, critical duty |

📊 Pressure Rating vs Temperature for Common Reactor Materials

This chart visualizes how allowable internal pressure drops with temperature for common Industrial Chemical Reactor materials. It supports reactor design decisions by comparing SS304, SS316/316L, and MS under the same geometry. For a chemical reactor manufacturer or industrial reactor supplier, this view helps match reactor applications to the correct material of construction (MOC) and temperature window.

📌 Observations:

As temperature rises, allowable pressure reduces across all MOCs; SS316/316L retains a slightly higher P–T envelope than SS304, especially above ~200 °C, while MS trends are competitive at moderate temperatures but require attention to corrosion and lining limits. MS (Rubber-Lined) is typically temperature-capped (≤100 °C) by the lining, even if the shell can bear more pressure. SV Industries engineers complete code-based thickness and nozzle/head checks, then aligns the P–T envelope with your process, utilities, and QA needs—improving reliability and uptime.

Thermal Management: Jacketed vs Limpet-Coil Reactors

Efficient heating & cooling decide batch safety, quality, and cycle time. We engineer your reactor’s thermal envelope—jacketed or limpet-coil—to deliver the right U×A (overall heat-transfer coefficient × area), stable temperature control, and safe exotherm management.

🔥 What this system does

- Ramp to setpoint quickly without hotspots

- Hold temperature during reaction (exothermic/endothermic)

- Cool-down to discharge safely and repeatably

Jacketed vs Limpet-Coil (quick comparison)

| Aspect | Jacketed Reactor | Limpet-Coil Reactor (Half-Pipe/Coil) |

|---|---|---|

| Overall Coefficient (U) | ~150–600 W/m²·K (service & flow dependent) | ~200–800 W/m²·K (often higher on service side) |

| Service Pressure & ΔT | Moderate; uniform coverage, lower service pressure | Higher allowable service pressures & ΔT on coil side |

| Cleanability | Smoother surface; easy CIP/SIP; hygienic finishes | Excellent process-side cleanability; external coil access |

| Maintenance | Fewer external welds; easy insulation/cladding | Modular repairs possible coil-by-coil |

| Best Use Cases | Multi-product, pharma/food, frequent cleaning | High heat flux, fast ramp/cool, rugged chemical duty |

🔧 U×A sizing (simplified)

- Required duty Q ≈ U × A × ΔTlm.

- As volume increases, U may drop (mixing & area/volume effects) → compensate with higher A and adequate utility flow.

- Agitation matters: better pumping (e.g., Hydrofoil/PBT) can raise U by improving film coefficients—see our Agitator.

💧 Utility & control tips

- Choose service: steam/hot oil for heating; chilled/brine/glycol for cooling.

- Prefer cascade/PID loops (process temp as master, utility valve as slave) to avoid overshoot.

- For strong exotherms, use semi-batch feeds and higher coil flow to keep ΔT in the safe zone.

📊 Heat Transfer Coefficient vs Reactor Volume

This chart shows how the overall heat transfer coefficient (U) changes with reactor volume in an Industrial Chemical Reactor. It matters because reactor design must maintain safe ramps/holds/cool-downs as size grows. For an experienced chemical reactor manufacturer or industrial reactor supplier, anticipating the U vs scale drop is crucial for time-to-spec and quality across reactor applications.

📌 Observations:

The negative slope confirms that larger reactors typically exhibit lower U due to film and mixing limits. To hit the same cycle time at scale, SV Industries compensates by increasing area (A), optimizing impeller selection/RPM, and ensuring adequate utility flow/ΔT. This improves industrial reactor mixing performance, supports impeller speed optimization in chemical reactors, and protects reactor efficiency vs agitator RPM—especially important for exothermic or tightly controlled processes.

📊 Heat Transfer Surface Area vs Reactor Capacity

This chart relates heat-transfer surface area to reactor capacity for a cooling duty in an Industrial Chemical Reactor. It supports reactor design decisions where buyers must meet strict cool-down windows. For a chemical reactor manufacturer or industrial reactor supplier, visualizing A vs capacity with heat-load context avoids undersized jackets/coils across varied reactor applications.

📌 Observations:

As capacity increases, required A and average Q˙\dot{Q}Q˙ rise proportionally for a fixed time. A limpet/half-pipe envelope (higher U) reduces area by roughly 25–35%, enabling compact insulation/cladding and shorter cooling cycles. SV Industries optimizes U×A, agitator selection/RPM, and utility flow to hit your cool-down targets—boosting industrial reactor mixing performance, impeller speed optimization in chemical reactors, and reactor efficiency vs agitator RPM.

📊 Jacketed vs Limpet Coil Heat Transfer Efficiency

This chart compares heat transfer efficiency (overall UUU) between jacketed and limpet-coil thermal envelopes as utility flow increases in an Industrial Chemical Reactor. It helps buyers and process engineers see how reactor design choices affect ramp/cool times. For a chemical reactor manufacturer or industrial reactor supplier, the comparison supports selecting the right envelope for specific reactor applications.

📌 Observations:

Across the same flow rates, limpet coils deliver higher hoh_oho and thus higher UUU due to higher service-side turbulence and pressure capability. Typical gains in UUU fall in the ~25–35% range under these assumptions, directly reducing required area or cycle time. SV Industries engineers U×A holistically—balancing envelope choice, impeller/RPM, and utility flow to achieve safe, repeatable heat-up and cool-down performance.

Agitation & Mixing: Impeller Selection, RPM & Torque Sizing

Efficient mixing cuts cycle time, stabilizes temperature, and improves conversion. We size the agitator–gearbox–shaft–impeller package to your viscosity, solids/gas load, and heat-transfer targets—so you hit the right mixing time at safe torque and power.

⚙️ Impeller Options (when to use what)

- Hydrofoil (Axial): High pumping, low shear; best for low–medium viscosity and heat transfer → Hydrofoil.

- Pitch Blade Turbine: Balanced shear + flow; versatile for blends, dispersions → PBT.

- Anchor / U-Anchor: Wall sweeping, gentle shear; viscous and heat-sensitive systems → Anchor Impeller.

- Helical Ribbon/Spiral: Very high viscosity, uniform top–bottom circulation → Helical.

- Specials: Rushton (gas–liquid), Paddle (shear-gentle) → Rushton · Paddle · Concave Disc.

📊 Quick Selection Guide

| Process / Viscosity | Typical Range | Recommended Impeller | RPM (indicative) | Notes |

|---|---|---|---|---|

| Blending, heat transfer (low μ) | 1–300 cP | Hydrofoil / PBT | 80–300 | High pumping; great U-value improvement |

| Suspending light solids | 1–500 cP | Hydrofoil (larger D/T) / PBT | 120–280 | Target Njs (just-suspension); add baffles |

| Viscous batches, heat-sensitive | 500–10,000 cP | Anchor / Helical | 20–120 | Wall sweep; maintain small tip clearance |

| Very high viscosity / pastes | >10,000 cP | Helical ribbon / Dual-shaft | 10–60 | Consider scrapers; torque-limited drive |

📊 Mixing Time vs Impeller RPM

This chart compares mixing time (tₘ) across different impeller RPM settings for three common designs—Hydrofoil, PBT, and Anchor—in an Industrial Chemical Reactor. It helps align reactor design with real performance expectations, supporting decisions for buyers working with a chemical reactor manufacturer or industrial reactor supplier across varied reactor applications.

📌 Observations:

As RPM rises, tₘ decreases non-linearly. Hydrofoil provides the shortest mixing times for low–medium viscosities with efficient pumping per kW, while PBT offers a good balance but draws higher power at the same RPM. Anchor excels in viscous or shear-sensitive media via wall-sweep, though at the same RPM it mixes slower—typically run at lower speeds with torque-capable drives. SV Industries optimizes industrial reactor mixing performance by matching impeller speed optimization in chemical reactors with geometry (D/T, baffles) and process needs, maximizing reactor efficiency vs agitator RPM.

Technical Specifications & Typical Ranges

| Parameter | Typical Range / Options | Notes & Customization |

|---|---|---|

| Working Volume | 100 – 20,000 L (larger on request) | Aspect ratio (H/T) ~1.0–1.5 for good mixing & heat transfer |

| Design Pressure (Vessel) | FV to ~10 bar(g) (process-dependent) | Higher ratings on request; hydrotested as per QAP |

| Design Temperature | −20°C to 250°C | Limited by MOC, seal, lining, and utilities |

| Material of Construction (MOC) | SS304, SS316/316L, MS (Rubber-Lined), specials on request | Choose by corrosion/cleanability; see **Materials & Construction** |

| Shell/Head Thickness | ~6 – 25 mm (indicative) | Engineered for P–T; corrosion allowance per spec |

| Head Type | Torispherical / Ellipsoidal | Dish-end geometry chosen for pressure & fabrication efficiency |

| Thermal Envelope | Jacketed or Limpet-Coil (half-pipe/coil) | See SS Jacketed Vessel and Limpet Coil Reactor Vessel |

| Service (Jacket/Coil) Pressure | ~3 – 16 bar(g) | Depends on utility (steam/hot oil/chilled/brine) & coil spec |

| Overall Heat-Transfer Coefficient (U) | ~150 – 800 W/m²·K | Varies with media, fouling, agitation, and utility side |

| Agitation System | Hydrofoil / PBT / Anchor / Helical | Impeller per rheology & duty → Agitator, Anchor, PBT, Hydrofoil, Helical |

| RPM (VFD-controlled) | ~20 – 300 RPM | Sized for mixing time, torque limits, and shear sensitivity |

| Motor Power | ~0.75 – 45 kW (typical) | Duty-based; service factor & start-up torque considered |

| Sealing | Mechanical seal (single/dual) or packing | Chosen for pressure, solvent duty, and hygiene |

| Nozzles & Instrumentation | Manway, charging, vent, dip pipe, RTD/TC, PG/PT, level | Additional ports for pH/flow/pressure; rupture disc/safety valve |

| Finish (Internal / External) | Ra ~0.8–1.6 μm / 2B or matt | Pickling & passivation; mirror finish on request |

| Insulation & Cladding | Mineral wool + SS cladding | Thickness per temperature profile & energy targets |

| Testing & QA | Hydrotest, leak test, NDT (as applicable) | MTC, WPS/PQR, QAP, FAT; audit-ready documentation |

| Mounting / Supports | Legs / Skirt / Lugs | As per foundation, seismic/wind, and access needs |

| Controls & Automation | VFD, PID loops, PLC/HMI (optional) | Data logging, interlocks, alarms as per URS |

📊 Internal Pressure vs Shell Thickness (per Material)

This chart shows how required shell thickness rises with design pressure for common Industrial Chemical Reactor materials—SS304, SS316/316L, and MS (SA-516)—including a corrosion allowance. It helps align reactor design with safe P–T envelopes. For a chemical reactor manufacturer or industrial reactor supplier, this view connects material choice to cost, weight, and fabrication practicality across reactor applications.

📌 Observations:

As pressure increases, thickness grows linearly, with SS316/MS needing slightly less thickness than SS304 at the same pressure (due to higher allowable stress in this illustration). The practical impact is lower shell weight and potentially easier heat transfer through the wall. SV Industries validates thickness via code calculations and integrates nozzle/head checks, CA, and QA—balancing safety, cost, and performance without overbuilding.

Applications & Industries We Serve

Where our chemical process reactors deliver results: from lab-scale validation to full-scale production, we engineer for conversion, safety, and cycle time across diverse sectors in India.

| Industry / Sector 🏭 | Typical Processes ⚗️ | Media / Conditions 💧🌡️ | Recommended Design Highlights 🔧 |

|---|---|---|---|

| Chemicals & Specialty Chemicals | Esterification, nitration, sulfonation, neutralization | Corrosive acids/alkali, exotherms | Limpet coil for high ΔT, baffles + Hydrofoil/PBT, SS316 |

| Pharmaceuticals / APIs | Crystallization, hydrogenation, acetylation | Solvents, pressure, GMP needs | Jacketed, mechanical seal, IQ/OQ docs, polished Ra |

| Dyes & Intermediates | Diazotization, coupling, sulfonation | Strong acids, temperature ramps | SS316/MS-RL as compatible, semi-batch feeds, robust cooling area |

| Agrochemicals | Neutralization, formulation, condensation | Suspensions, shear sensitivity | PBT/Hydrofoil for pumping, VFD control, CIP-friendly nozzles |

| Polymers / Resins / Adhesives | Polymerization, condensation, curing | High viscosity, heat removal | Anchor/Helical, wall-sweep, high-area coils |

| Paints & Coatings | Dispersion, let-down, blending | Pigments, thixotropy | PBT with baffles, bottom clearance tune, Njs focus |

| Surfactants & Home Care | Saponification, ethoxylation (downstream) | Foaming, heat release | Axial impellers, anti-foam provisions, cascade temperature control |

| Food & Flavours | Emulsification, extraction, blending | Hygienic finishes | Jacketed SS316L, CIP/SIP ports, mirror/internal Ra as specified |

| Biofuels / Oleochemicals | Transesterification, washing, drying | Solvents, phase separation | Jacketed + decant nozzles, controlled agitation, seal selection |

| ETP/STP / Water Treatment | pH correction, coagulation, flocculation | Continuous duty, abrasives | Agitator duty sizing, rugged bearings, Agitator integration |

Why Choose SV Industries for Chemical Process Reactors

Engineered for performance, built for reliability. Here’s why process manufacturers across India trust SV Industries for their chemical process reactors:

- ⚙️ Process-first design: We size your reactor from first principles—U×A for heat load, mixing time/torque for rheology, and safe P–T margins—so batches hit conversion and cycle-time targets.

- 🌡️ Thermal expertise: Jacketed and limpet-coil envelopes tuned to your utilities and ΔT. Explore options: SS Jacketed Vessel · Limpet Coil Reactor Vessel.

- 🌀 Mixing that works: Correct impeller + RPM for uniformity and heat removal—Hydrofoil, PBT, Anchor, Helical. See: Agitator, Anchor, PBT, Hydrofoil, Helical.

- 🛡️ Materials & construction: SS304/SS316/MS-RL per corrosion profile; qualified WPS/PQR, controlled heat input, pickling/passivation, and audit-friendly finishes.

- 📁 QA & documentation: MTC, hydrotest, leak/NDT (as applicable), QAP, FAT support, and IQ/OQ assistance for regulated environments.

- 🔌 Automation-ready: VFDs, interlocks, and PID temperature/pressure control; PLC/HMI integration on request.

- 🧩 True customization: Nozzle maps, CIP/SIP, insulation & cladding, mechanical seals, skids, and instrumentation tailored to your SOPs.

- 🚚 Pan-India delivery & install: GA drawing reviews, site coordination, commissioning, and operator training—plus responsive spares/support.

- 🧭 Transparent collaboration: Clear design reviews (P–T envelope, nozzle layout, agitation spec) and proactive risk notes for exotherms, fouling, or shear-sensitive media.

- 📷 Proof of work: Browse real builds and finishes in our Gallery and technical explainers on our Blog.

Ready to engineer your reactor around your chemistry?

Talk to an engineer → Contact Us · Learn more → Chemical Process Reactor · Related hardware → Storage Tank.

How to Choose the Right Chemical Process Reactor

Pick a chemical process reactor by matching your chemistry & kinetics with the right operation mode (Batch/Semi-batch/CSTR/PFR), material of construction (MOC), thermal envelope (jacket or limpet-coil), and agitation. Size for your heat load (U×A), viscosity/mixing time, and safe pressure–temperature limits—then validate cleanability and documentation.

✅ Quick Checklist (what to decide first)

- Process mode: Batch/Semi-batch for flexibility; CSTR/PFR for steady throughput.

- MOC: SS304/SS316/MS-RL based on corrosion & hygiene (cleanability/finish).

- Thermal design: Jacket (hygienic, uniform) vs Limpet-coil (higher service pressure/ΔT).

- Agitation: Hydrofoil/PBT (low–medium μ) vs Anchor/Helical (high μ); baffles for vortex control.

- P–T envelope: Design pressure & temperature with margin; choose seal (mechanical/packing).

- QA & docs: MTC, hydrotest, NDT (as applicable), QAP/FAT, IQ/OQ readiness.

- Scale-up: Account for U drop with volume; compensate with area, flow, and impeller sizing.

🧪 Decision Matrix

| Factor | Why it matters | What to share | Design implications | Typical choices / Links |

|---|---|---|---|---|

| Reaction mode & kinetics | Determines residence time & control strategy | Target conversion, exotherm/endotherm, selectivity | Batch/Semi-batch vs Continuous (CSTR/PFR) | See Design types |

| Corrosion & hygiene | Material life, surface finish, cleanability | pH, chlorides, solvents, cleaning method | MOC & finish spec (Ra), passivation | SS304 / SS316 / MS-RL — Reactor Vessel |

| Heat load (kW) & ΔT | Cycle time & safety for exotherms | Duty (kW), utility temps, fouling tendency | Size **U×A**; pick jacket or limpet | Jacketed · Limpet-coil |

| Rheology (μ, SG, solids%) | Impeller type, RPM, motor/torque | Viscosity range, solids %, gas load | Axial vs wall-sweep; VFD; baffles | Agitator · Anchor · PBT · Hydrofoil · Helical |

| Pressure–Temperature | Safety envelope & seal choice | Max/min T, design P, vacuum? | Shell/head thickness, seal spec | See Materials section; compliance docs |

| Validation & cleaning | Downtime & audit readiness | CIP/SIP need, sampling, documentation | Nozzle map, Ra, doc pack (IQ/OQ) | Industrial Chemical Reactor |

🌡️ Jacket vs Limpet — quick rule-of-thumb

- Choose Jacketed when hygiene/CIP, multi-product flexibility, and uniform coverage matter → SS Jacketed Vessel.

- Choose Limpet-coil when you need higher service pressure/ΔT and faster ramp/cool → Limpet Coil Reactor Vessel.

🌀 Agitator Selection (at a glance)

- Low–medium viscosity: Hydrofoil/PBT at moderate RPM for strong pumping & heat transfer.

- High viscosity / shear-sensitive: Anchor/Helical with wall-sweep and tight tip clearance.

Explore: Agitator.

🧰 “Spec Pack” — minimum info to get your design right

- Capacity (working & total), media & solids %, viscosity range (cP), SG

- Heat load (kW), target heat-up/hold/cool times, utility temps/pressures

- Design P–T (incl. vacuum), cleaning/validation needs, hazardous area (if any)

- Preferred mode (Batch/Semi-batch/CSTR/PFR), CIP/SIP, automation level (VFD/PLC/HMI)

Need help choosing? Share your “Spec Pack” and we’ll propose the right chemical process reactor with U×A and agitator sizing.

📞 Talk to an Engineer: Contact Us · 🔍 See builds: Gallery · 📚 Learn more: Chemical Process Reactor.

FAQs: Technical Answers on Chemical Process Reactors

What’s the fastest way to estimate heat-transfer area (U×A) for my batch?

Use Q = U × A × ΔTₗₘ. Start from duty (kW) and realistic U (150–800 W/m²·K); then select A and confirm utility flow/pressure.

Pick ΔTₗₘ from utility/product curves, assume conservative U (fouling + mixing). Scale A via jacket/limpet geometry and re-check ramp, hold, cool times. See: SS Jacketed Vessel · Limpet Coil Reactor Vessel.

Jacketed vs limpet-coil: which gives better control for exotherms?

Limpet-coil often handles higher service pressure/ΔT and rapid heat removal; jacketed offers uniform coverage and hygienic cleanability for multi-product plants.

Which impeller should I use for high-viscosity resin at low shear?

Use Anchor or Helical ribbon with wall-sweep and tight tip clearance; run lower RPM with a torque-capable gearbox/VFD.

How does scale-up affect my U value and cycle time?

As volume increases, U typically drops due to poorer film coefficients and longer diffusion paths—compensate with more area, better pumping, and higher utility flow.

Do I need SS316 or is SS304 enough for chloride-bearing media?

For chlorides or pitting-risk media, SS316/316L is safer than SS304; for aggressive acids, consider MS-rubber-lined or special alloys.

Batch, CSTR, or PFR — which mode suits fast, exothermic reactions?

Semi-batch (staged feeds) improves safety/selectivity; CSTR stabilizes temperature at steady throughput; PFR suits suitable kinetics and high conversions.

For strong exotherms, staged dosing plus high U×A reduces spikes. See Reaction Time vs Reactor Type chart and our overview: Chemical Process Reactor.

How do I estimate mixing time quickly?

Use tₘ ∝ (T/N·φ) as a thumb-rule: higher RPM (N), optimized impeller diameter D/T, and baffles reduce tₘ; confirm with trials.

Mechanical seal or gland packing — what should I choose?

Use mechanical seals for pressure/solvent duty and emission control; packing is acceptable for low-pressure, non-hazardous services.

How do I avoid temperature overshoot during heat-up?

Use cascade/PID control with process temperature as master, limit steam valve opening rate, and pre-tune utility flow/pressure.

What minimum data do you need to propose the right reactor?

Share capacity, media/viscosity, heat load (kW), target times (heat/hold/cool), utilities, design P–T, cleaning/validation needs, and preferred mode.