Concave Disc Impeller Manufacturer in India – SV Industries

At SV Industries, we take pride in being one of the leading Concave Disc Impeller manufacturers in India, trusted by clients across chemical, pharmaceutical, food processing, and allied industries. With over a decade of hands-on experience in agitator and impeller design, we specialize in delivering solutions that ensure efficient mixing, reduced power consumption, and long operational life.

Our in-house manufacturing facility in Ahmedabad, Gujarat, is fully equipped with advanced CNC systems and precision tools, enabling us to manufacture impellers in SS304, SS316L, Duplex Steel, and custom-grade alloys. All products are manufactured under strict ISO-certified quality systems, ensuring dimensional accuracy and material traceability.

From high-viscosity fluids in chemical reactors to clean mixing applications in pharmaceutical vessels, our Concave Disc Impellers are built for consistent performance and industry-specific reliability.

Learn more about our values, infrastructure, and client-centric approach on our

👉 About Us page.

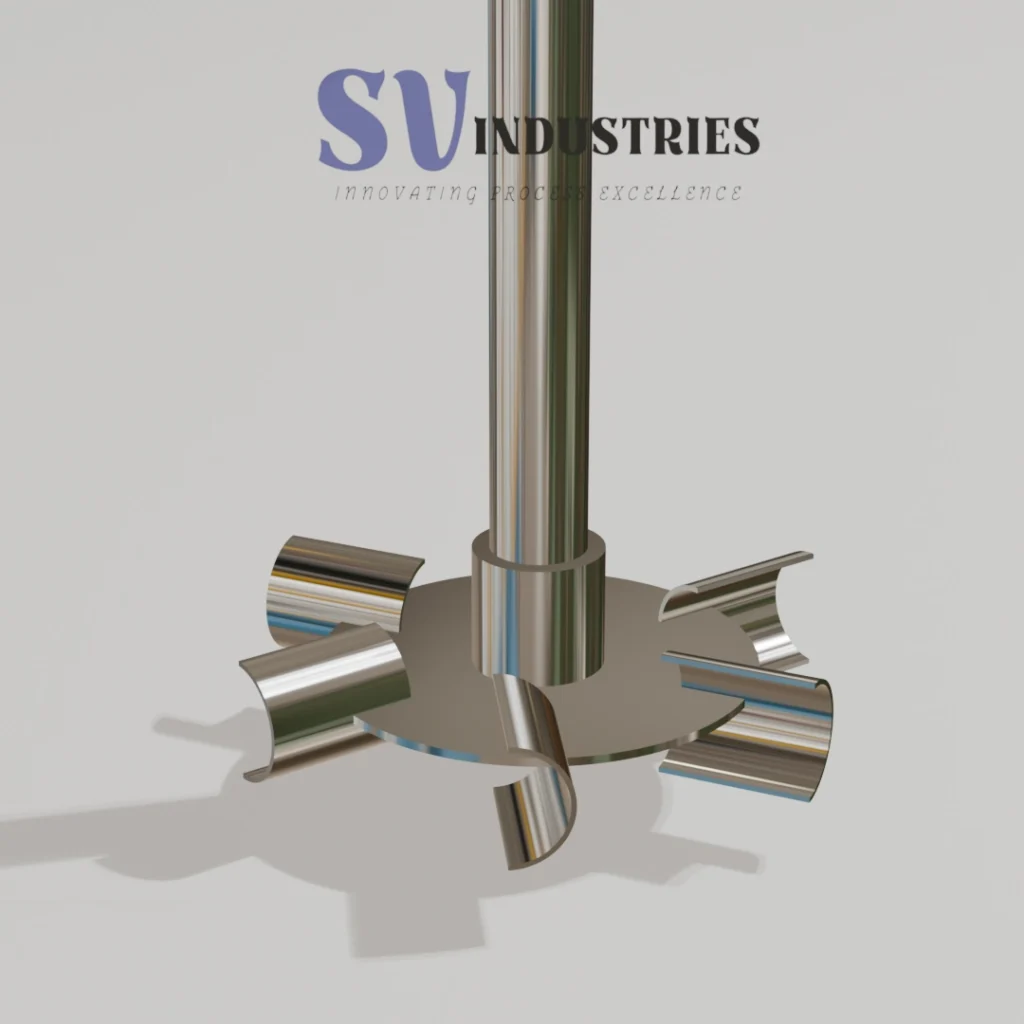

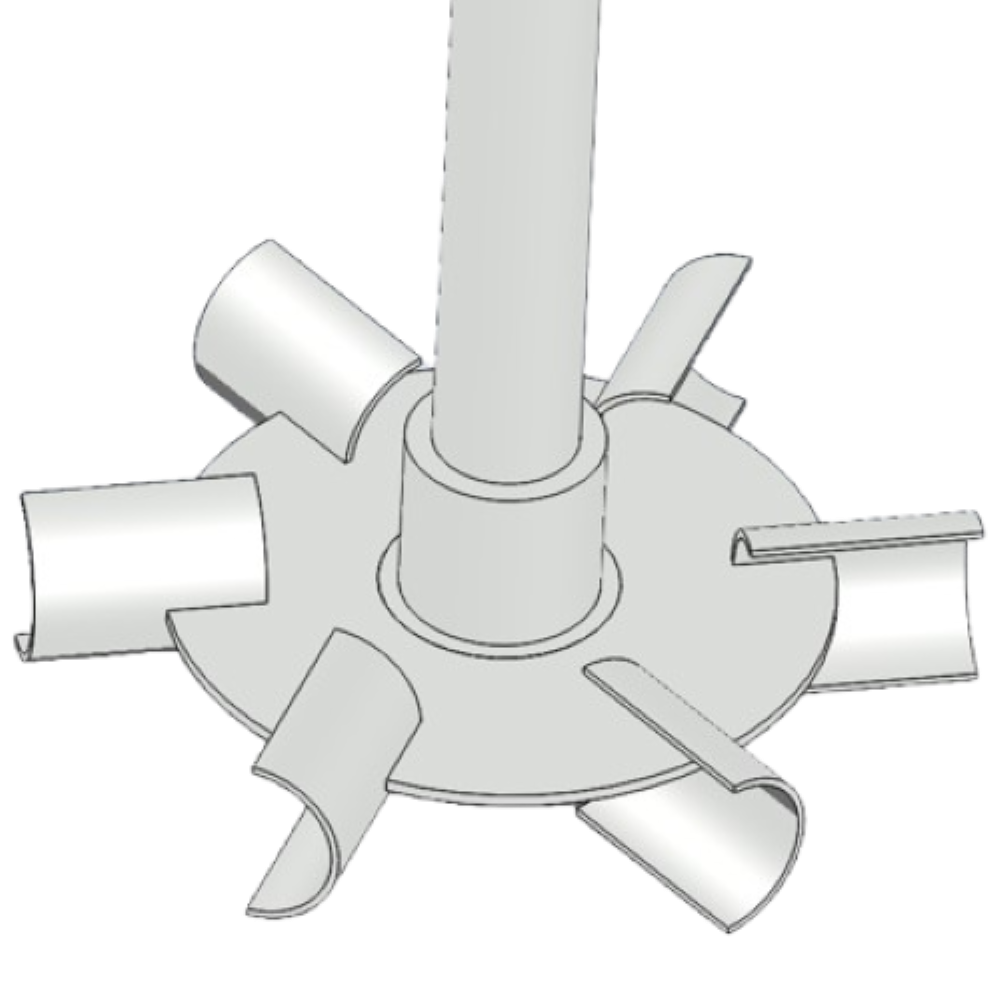

What is a Concave Disc Impeller? – Definition & Overview

A Concave Disc Impeller is a specially engineered mixing blade designed for high-efficiency blending of low to medium-viscosity fluids in industrial reactors.

❓ What is a Concave Disc Impeller?

A Concave Disc Impeller is a curved disc-shaped mixing device used to create smooth, controlled flow in liquid processing — ideal for applications needing gentle yet thorough mixing.

🏭 Where Is It Used?

You’ll commonly find Concave Disc Impellers in:

✅ Chemical Reactors

✅ Pharmaceutical Mixing Tanks

✅ Food & Dairy Processing Units

✅ Paints, Inks & Coatings Industry

It is a preferred choice when you’re dealing with emulsions, suspensions, or products that need gentle yet effective agitation.

⚙️ How Does It Work?

The impeller features a concave central disc with strategically curved blades that direct the fluid axially and radially. This creates a controlled vortex-free flow, enabling better product uniformity, low shear, and less energy consumption.

Its advanced geometry helps:

Maintain flow even at lower speeds

Reduce foaming in sensitive processes

Improve mixing consistency across the tank

🤝 Not Sure Which Impeller Suits Your Process?

We can help! Our experts at SV Industries will recommend the best impeller based on your application, fluid type, and reactor size.

👉 Contact Us Now for free consultation or a custom quote.

Working Principle of a Concave Disc Impeller

A Concave Disc Impeller operates on the principle of axial-radial hybrid flow, delivering controlled turbulence and optimal shear for efficient mixing, even in complex fluid systems.

🌊 Flow Behavior & Fluid Dynamics

The impeller’s concave disc and swept-back blades are designed to manipulate fluid dynamics within the tank. As the impeller rotates:

Axial flow (fluid moving up and down) is promoted from the blade curvature

Radial discharge (fluid pushed outward from the impeller) creates uniform circulation

The concave design reduces vortex formation, enabling energy-efficient agitation

This unique geometry provides a stable flow field, minimizing dead zones and ensuring consistent suspension and dispersion of ingredients.

🌀 Suction-Lift & Cavitation Resistance

Thanks to its aerodynamic blade profile and hollow disc shape:

The impeller creates a suction-lift effect, pulling fluid from the bottom of the tank upward

This enables excellent solid suspension and gas dispersion

The structure helps resist cavitation, even at higher RPMs or in low-pressure zones, increasing the impeller’s life and reliability

✅ Mixing Actions of Concave Disc Impeller

✅ Gentle but effective blending of viscous and shear-sensitive fluids

✅ Improved gas-liquid mixing without bubble coalescence

✅ Enhanced mass transfer rate for emulsions and suspensions

✅ Ideal for batch and continuous processing across industries

🔍 Looking for a Comparison?

See how this impeller stands against others:

👉 Anchor Impeller – for heavy-duty mixing

👉 Hydrofoil Impeller – for high flow, low shear

👉 Paddle Impeller – for basic blending tasks

Design Features of SV Industries' Concave Disc Impeller

At SV Industries, our Concave Disc Impellers are engineered with precision to deliver superior mixing performance, durability, and energy efficiency — tailored for a wide range of industrial applications.

🔄 Advanced Blade Geometry

Our impellers feature a deep concave disc with aerodynamically curved blades that optimize fluid flow in both axial and radial directions. This unique shape:

Minimizes vortexing and air entrapment

Ensures uniform dispersion of particles

Reduces power draw while maximizing flow rate

The rounded disc edges reduce turbulence spikes and shear hotspots, making it suitable for shear-sensitive fluids.

🔗 Shaft Coupling Options

We offer versatile shaft coupling designs to fit a variety of agitator drive systems:

Standard fixed shaft

Flange-mounted options

Quick-release couplings for ease of maintenance

Each coupling type is engineered for stability under dynamic load, ensuring minimal vibration and long operational life.

🧩 Customization Options

Our Concave Disc Impellers are fully customizable to match your process requirements and reactor configurations:

Material options: SS316L, SS304, Hastelloy, Duplex Steel

Diameter and blade angle modifications

Coatings for corrosion or abrasion resistance

Available for batch or continuous flow setups

Need a complete mixing system? Explore our Agitator Category to integrate the right drive, seal, and mounting assembly with your impeller.

💡 Why SV’s Design Stands Out

Unlike generic impellers, ours are built to:

Withstand high mixing loads

Minimize wear over time

Improve mixing uniformity at lower RPMs

Types of Concave Disc Impeller

Not all mixing challenges are the same — and neither are impellers. At SV Industries, we manufacture different types of Concave Disc Impellers to match your specific process requirements — whether it’s high-shear blending or gentle agitation.

🔍 Classification by Design & Function

| Type | Description |

|---|---|

| Single-Stage | Ideal for low to moderate mixing depths. Simple design, easy maintenance. |

| Multi-Stage | Best for deep tanks or high-viscosity fluids. Offers multiple shear zones. |

| Open Blade | Suitable for non-clogging operations with better flow-through and drainage. |

| Closed Blade | Used in clean-in-place (CIP) setups and for better product containment. |

✅ Other Custom Variants Include:

Tapered-blade impellers for reduced cavitation

Slotted-disc models for improved gas dispersion

Hollow-disc designs to reduce weight without sacrificing performance

Each impeller can be tailored to blade thickness, diameter, and blade angle, based on fluid characteristics and tank geometry.

Performance Characteristics of Concave Disc Impeller

The performance of a Concave Disc Impeller is highly influenced by factors like fluid viscosity, tank geometry, flow rate, and RPM. At SV Industries, we validate every impeller design with real-world performance testing to ensure efficiency, consistency, and reliability.

Below are selected charts showcasing how our impeller behaves across key performance parameters:

⚡ Energy Consumption of Concave Disc Impeller Across Different Flow Rates

Understanding how power input changes with flow rate is critical for optimizing mixing efficiency and managing operational costs. This performance curve helps engineers evaluate the energy footprint of the Concave Disc Impeller across different process conditions.

📌 What This Chart Tells You

At low to medium flow rates, the power consumption of the Concave Disc Impeller remains relatively stable, thanks to its radial flow design and optimized blade geometry.

As flow demand increases, there is a gradual rise in power usage—indicating an efficient energy-to-flow ratio, ideal for processes needing uniform mixing with low energy spikes.

This makes it superior to high-shear options like the Rushton Turbine for applications focused on thermal stability and sensitive reactions.

✅ Ideal For

Energy-conscious manufacturing plants

Reactor vessels processing low to medium viscosity fluids

Continuous or batch mixing systems where predictable energy usage is key

💡 Pro Tip

Unlike traditional high-torque impellers, Concave Disc Impellers deliver consistent performance across flow variations—reducing wear on motor components and extending equipment lifespan. For high-viscosity applications with higher power demands, explore our Anchor Impeller or Paddle Impeller.

⚙️ Mixing Efficiency Curve of Concave Disc Impeller Based on Flow Rate

When selecting an impeller, balancing mixing efficiency with flow rate demands is essential for cost-effective processing. This chart maps how the Concave Disc Impeller performs as flow rate increases—enabling smarter decisions around energy consumption, process throughput, and scalability.

📌 What This Chart Reveals

At low to moderate flow rates, the Concave Disc Impeller demonstrates high mixing efficiency, making it ideal for reactions requiring precision and control.

As flow rate continues to rise, efficiency stabilizes—providing consistent radial flow without drastic increases in energy input.

The impeller maintains effective mixing behavior without causing turbulence overload, which is particularly valuable in sensitive mixing operations such as pharmaceutical and chemical processing.

✅ Perfect For Applications Involving:

Controlled fluid mixing in low to medium viscosity ranges

Reactor vessels requiring balance between shear and flow

Batch processes where stable, repeatable mixing cycles are crucial

💡 Pro Tip

Unlike high-shear impellers like the Rushton Turbine, Concave Disc Impellers operate with energy consistency, helping reduce wear on components and minimizing operational variability over time.

Looking to switch from inefficient impellers? Compare performance with the Anchor Impeller or Hydrofoil Impeller to find your best fit.

⚡ Pressure Drop Characteristics of Concave Disc Impeller vs Flow Rate

When designing an efficient mixing system, understanding how pressure drop changes with flow rate is essential. This chart highlights how the Concave Disc Impeller minimizes system resistance, making it an excellent choice for applications that require steady flow with minimal back pressure.

📌 What This Chart Reveals

At low to moderate flow rates, the pressure drop remains minimal, ensuring smooth operation and reduced stress on pump systems.

As flow rate increases, there’s only a gradual rise in pressure, unlike other impellers that exhibit sharp spikes—demonstrating the fluid-friendly design of the Concave Disc Impeller.

This makes it a low-resistance mixing solution, especially suited for closed-loop reactor systems, heat exchangers, and energy-efficient fluid processing units.

✅ Ideal For

Thermal-sensitive mixing operations where pressure build-up can disrupt stability

Pumping systems that demand consistent pressure profiles

Pharmaceutical and chemical reactors requiring precise flow control

💡 Pro Tip

Using an impeller with a lower pressure drop reduces energy consumption across pumping and mixing stages, extending the life of associated equipment. For more aggressive flow requirements, consider pairing with Hydrofoil Impellers or integrating into a Jacketed Vessel System for optimal results.

🔗 Explore Related Products

Applications of Concave Disc Impellers Across Industries

Concave Disc Impellers are engineered for versatility and high-efficiency mixing, making them a go-to solution across a wide range of process-driven industries. Their ability to handle fluids of varying viscosities while minimizing shear and energy loss gives them a unique advantage.

✅ Industries That Rely on Concave Disc Impellers:

Pharmaceuticals:

Uniform suspension of APIs, granulation liquids, and sterile mixingChemicals:

Homogeneous blending of reagents, catalysts, and intermediate compoundsFood & Beverage:

Mixing syrups, flavorings, and emulsions without degrading textureCosmetics & Personal Care:

Stable mixing of creams, lotions, and viscous formulationsWater Treatment & Effluent Plants:

Dissolution of flocculants, polymers, and sediment agitatorsPaints, Inks & Pigments:

High-shear dispersion of solids in liquids with precise consistency

🌊 Types of Media Handled:

✅ Low-viscosity liquids (solvents, water-based solutions)

✅ Medium-viscosity fluids (syrups, emulsions, polymer slurries)

✅ High-viscosity compounds (gels, creams, sludge, resin systems)

📊 Fluid Viscosity Compatibility of Concave Disc Impeller – Application Suitability Chart

Understanding where Concave Disc Impellers excel is crucial to optimizing your mixing performance. The following chart maps the effectiveness of Concave Disc Impellers across various fluid viscosity ranges, helping engineers and plant managers make data-backed equipment choices.

📌 Chart Interpretation: Where Concave Disc Impellers Perform Best

As shown in the Fluid Viscosity vs Application Suitability chart, Concave Disc Impellers offer exceptional performance in low to medium-viscosity fluids. Their unique curved disc design generates a balance of radial flow and moderate shear, making them ideal for:

Liquid-liquid mixing

Gas dispersion

Heat-sensitive fluids

Reactor-based blending

For high-viscosity fluids, alternate impellers like the Anchor Impeller or Helical Impeller may provide better flow coverage and torque management.

When you’re deciding on an impeller, this chart acts as a quick decision-making guide—ensuring you align your process fluid characteristics with the most efficient impeller geometry.

🔍 Still unsure which impeller fits your application? Talk to our experts or visit our Agitator Selection Guide to explore further.

Viscosity Impact on Mixing Performance

Understanding how fluid viscosity influences mixing is critical when choosing the right impeller.

🌊 Why Viscosity Matters in Mixing

Viscosity, or fluid thickness, directly impacts how an impeller behaves during agitation. As viscosity increases, the flow pattern shifts from turbulent to laminar, requiring more power and torque to maintain uniform mixing.

Low-viscosity fluids (e.g., water, alcohol) allow for rapid flow and high turbulence.

High-viscosity fluids (e.g., gels, creams, slurries) create resistance, slowing down the impeller’s efficiency unless it’s specifically designed for such loads.

⚖️ Newtonian vs Non-Newtonian Fluids – Quick Guide

| Type | Description | Examples |

|---|---|---|

| Newtonian Fluids | Viscosity remains constant regardless of shear rate. | Water, oils, alcohols |

| Non-Newtonian Fluids | Viscosity changes with shear rate—thicker or thinner under force. | Sludge, polymer gels, paints |

Knowing the type of fluid is essential for choosing the correct impeller geometry and speed.

🧩 Best Practices for Impeller Selection

Choose Concave Disc Impellers for low to medium viscosity with consistent flow demands.

For non-Newtonian or high-viscosity media, explore alternatives like:

💬 Not sure what suits your process best?

Contact SV Industries for expert guidance tailored to your fluid properties and tank design.

⚡ Concave Disc Impeller Performance vs Fluid Viscosity Chart

Understanding how fluid viscosity impacts the performance of the Concave Disc Impeller is crucial for selecting the right impeller for your mixing process. This chart illustrates the impeller’s efficiency across a wide range of fluid viscosities, helping engineers optimize mixing quality and energy use.

📌 What This Chart Reveals

The Concave Disc Impeller maintains high performance and stable flow in low to medium viscosity fluids, making it ideal for a variety of industrial processes.

As viscosity increases, mixing efficiency may slightly reduce, but the impeller’s unique design ensures effective shear and circulation even with thicker fluids.

This performance consistency translates into energy savings and process reliability across different fluid conditions.

✅ Ideal For

Mixing chemicals, pharmaceuticals, and food products with varying viscosities

Processes requiring consistent shear rates and homogeneous blending

Applications where energy efficiency and reliable mixing are top priorities

💡 Pro Tip

For highly viscous fluids, consider combining the Concave Disc Impeller with complementary impellers like the Anchor Impeller to enhance mixing and reduce power consumption.

Technical Specifications and Material Grades of Concave Disc Impeller

Designed for precision, performance, and durability—our Concave Disc Impellers are engineered to meet the toughest industrial standards.

📐 Standard Specifications

| Parameter | Specification Range |

|---|---|

| Impeller Diameter | 150 mm to 1800 mm |

| Operational Speed | 50 to 1440 RPM |

| Torque Capacity | 30 Nm to 850 Nm |

| Blade Thickness | 3 mm to 12 mm |

| Coupling Options | Keyed / Flanged / Threaded Shaft |

| Installation Type | Top Entry / Side Entry |

| Surface Finish | Up to 0.6 Ra (CIP/SIP Optional) |

| Pressure Rating | Up to 5 Bar Internal Tank Pressure |

| Operating Temperature | -10°C to 200°C (Material Dependent) |

| Balancing | ISO 1940 G6.3 Dynamic Balancing |

📎 Note: Custom designs available on request based on tank size, fluid type, and agitation goals.

🧪 Material Grades Available

We offer a wide range of materials for compatibility with corrosive, high-temperature, or sanitary processing environments:

Stainless Steel 304 – General-purpose industrial mixing

Stainless Steel 316L – High corrosion resistance for pharmaceuticals

Hastelloy C-276 – Suitable for aggressive chemicals and acids

Duplex Steel – High strength and excellent chloride resistance

📜 All materials are certified to meet ASME, ISO, and GMP compliance where required.

🏷️ Certifications & Pressure Ratings

ISO 9001:2015 Quality Certified

GMP Compliance (for pharma-grade impellers)

Pressure Handling: Up to 5 bar internal tank pressure

Surface Finish: Up to 0.6 Ra for cleanability (CIP/SIP available)

⚡ Torque Requirements of Concave Disc Impeller Across RPM Levels

Understanding the torque requirements at different RPM (rotations per minute) is key to designing reliable and energy-efficient mixing systems. This chart demonstrates how the Concave Disc Impeller responds to changes in speed, helping engineers select the right motor and drive for smooth, stable operation.

📌 What This Chart Reveals

At lower RPMs, the torque remains relatively stable, ensuring smooth startups and minimal mechanical stress.

As RPM increases, torque rises steadily to match the growing resistance of the fluid, maintaining consistent mixing power.

This characteristic allows for precise control during varying process stages, reducing wear and optimizing energy consumption.

✅ Ideal For

Applications requiring controlled speed ramp-up without sudden torque spikes

Processes involving viscous fluids where torque needs vary with speed

Designing motors and gearboxes for efficient, long-lasting agitator performance

💡 Pro Tip

Pair your Concave Disc Impeller with SV Industries’ custom industrial agitators engineered for optimal torque delivery. For high-torque, low-speed mixing, explore our Rushton Turbine solutions.

⚡ Impact of Impeller Speed on Mixing Efficiency at Various Flow Rates

Balancing impeller speed with flow rate is vital to achieving optimal mixing efficiency without excessive energy consumption or equipment wear. This performance curve reveals how the Concave Disc Impeller adapts across a range of speeds to deliver consistent, energy-smart flow.

📌 What This Chart Reveals

At moderate speeds, the impeller achieves a peak efficiency zone, where flow rate is maximized relative to power input, ideal for routine industrial mixing tasks.

Increasing speed beyond this zone results in diminishing returns as flow efficiency plateaus or declines slightly due to turbulence and shear forces.

The design ensures stable flow profiles even at variable speeds, making it a versatile choice for applications requiring frequent speed adjustments.

✅ Ideal For

Processes requiring variable speed control to match changing batch sizes or reaction conditions

Industrial reactors and mixers where energy efficiency is a priority

Plants focused on reducing wear and tear while maintaining consistent product quality

💡 Pro Tip

Pair your Concave Disc Impeller with SV Industries’ industrial agitators featuring advanced motor controls for precise speed regulation and enhanced process reliability. For applications demanding higher flow at consistent speeds, consider our Hydrofoil Impeller.

Concave Disc Impeller Performance Comparison with Other Impellers

When selecting the right impeller for your mixing process, understanding the performance differences between leading designs is essential. Below is a detailed comparison of the Concave Disc Impeller vs. Hydrofoil Impeller vs. Anchor Impeller based on critical parameters such as shear rate, energy consumption, and flow type.

🔍 Impeller Performance Comparison Table

| Impeller Type | Shear Rate | Energy Consumption | Flow Pattern |

|---|---|---|---|

| Concave Disc Impeller | Medium to High | Moderate | Radial + Mild Axial |

| Hydrofoil Impeller | Low | Low | Strong Axial Flow |

| Anchor Impeller | Low | High | Laminar Flow |

📈 Interpreting the Data

The Concave Disc Impeller offers a balanced performance profile, making it suitable for a wide range of medium-to-high shear mixing applications. It delivers moderate energy consumption while generating both radial and mild axial flow, which improves overall mixing homogeneity and suspension of solids. This makes it ideal for viscous fluids and multi-phase blending tasks where uniform mixing is essential.

In contrast, the Hydrofoil Impeller excels in low-shear, energy-efficient applications. Its strong axial flow is ideal for bulk fluid circulation in low-viscosity systems, but it may not perform as effectively in applications requiring high shear.

The Anchor Impeller is typically used in very high-viscosity environments, offering laminar flow and maximum wall scraping efficiency. However, its high energy requirement and low shear rate make it less suitable for fine dispersion or emulsification processes.

✅ Choosing the Right Impeller

If your process demands moderate energy usage with efficient shear and flow combination, the Concave Disc Impeller strikes the right balance. For gentle mixing, the Hydrofoil Impeller is a great option, while the Anchor Impeller is ideal for viscous material handling.

Explore more about our:

⚡Performance Comparison of Concave Disc, Hydrofoil, and Anchor Impellers

Choosing the right impeller is essential for optimizing mixing efficiency, energy consumption, and process outcomes. This comparative chart highlights the key performance differences between the Concave Disc, Hydrofoil, and Anchor Impellers, helping you make an informed choice for your industrial mixing needs.

📌 Interpretation

The Concave Disc Impeller offers a balanced mix of shear and flow, making it versatile for medium-viscosity fluids and processes needing efficient circulation without excessive energy use.

The Hydrofoil Impeller is designed for energy-efficient axial flow, excelling in applications where low shear and high flow rates are critical, such as in blending and heat transfer.

The Anchor Impeller is best suited for high-viscosity fluids, providing gentle mixing with radial flow, but it consumes more power due to its large contact surface.

This comparison helps plant engineers and process designers select the right impeller based on fluid properties, energy budgets, and mixing goals.

🔗 Explore Related Products

📞 Need Help Choosing the Best Impeller for Your Process?

Contact SV Industries experts for tailored advice and custom impeller solutions.

👉 Request a Consultation

Why Choose SV Industries for Concave Disc Impellers

At SV Industries, we don’t just manufacture Concave Disc Impellers—we engineer precision solutions tailored to your mixing challenges. With years of industrial expertise, advanced facilities, and a reputation for reliability, here’s why industries across India trust us for their critical mixing needs:

✅ In-House Foundry & Manufacturing Facility – We control quality from start to finish with our own casting and fabrication units, ensuring superior build, finish, and performance.

🔍 Strict Quality Assurance at Every Stage – Our multi-stage QA process ensures that every Concave Disc Impeller meets ISO-certified standards for durability, balance, and mixing efficiency.

🧪 Custom R&D & Process Engineering Support – Need a unique impeller for a complex application? Our in-house R&D team works closely with you to develop tailored designs that optimize flow dynamics and energy usage.

🛠️ Precision-Built for Process Industries – Each impeller is engineered for performance in chemical reactors, blending vessels, and multi-phase mixers, and is compatible with custom-designed agitators.

🌟 Trusted by Leading Brands Across India – With a strong client base in pharmaceuticals, chemicals, food processing, and more, we’ve built long-term relationships through consistent delivery and performance.

⭐ Positive Google Reviews & Industry Reputation – Our 4.9★ Google rating reflects our commitment to customer satisfaction, technical excellence, and after-sales service.

📩 Ready to discuss your requirement? Visit our Contact Us page or send an enquiry now and our team will assist you with the right solution.

Choosing the Right Concave Disc Impeller Manufacturer

Selecting the ideal Concave Disc Impeller manufacturer is crucial to the performance and reliability of your industrial mixing systems. Whether you’re in chemical processing, pharmaceutical production, or food-grade blending, the right partner ensures you receive not just a product—but a tailored, technically sound solution.

Use the following checklist to evaluate potential suppliers:

✅ Concave Disc Impeller Manufacturer Evaluation Checklist

| Key Factors | What to Look For | SV Industries Advantage |

|---|---|---|

| Industry Experience | Proven track record in supplying impellers for various industries | 4+ years in agitator and impeller manufacturing |

| Delivery Time | Fast production and dispatch with clear timelines | Optimized workflow ensures on-time delivery across India |

| Customization Capability | Ability to tailor impeller geometry for viscosity, tank shape, and flow requirements | R&D team designs custom impellers for process-specific needs |

| Quality Certifications | ISO certifications, material traceability, balance testing reports | Fully ISO-certified, with strict QA and documentation |

| Technical Support | Assistance in selection, installation, and post-sale services | Engineering support + installation guidance |

| Client Portfolio | Trusted by recognized brands in your industry | Serving major clients in chemicals, pharma, food, and biotech |

🛠️ Making the Right Choice

Your impeller isn’t just a component—it’s the heart of your mixing operation. A poorly chosen manufacturer may lead to inconsistent performance, increased downtime, or premature wear. That’s why partnering with a reputed, technically strong manufacturer like SV Industries ensures reliability, support, and long-term value.

📩 Need help choosing the right impeller for your system? Talk to our experts today or send a direct product enquiry to get started.

Frequently Asked Questions (FAQs) ) about Concave Disc Impeller

What is a concave disc impeller used for?

Concave disc impellers are used for mixing liquids, suspensions, and slurries, providing efficient agitation with minimal shear.

How does a concave disc impeller work?

The concave blades generate a swirling vortex that enhances fluid circulation and ensures uniform mixing.

What industries use concave disc impellers?

They are used in chemical processing, pharmaceuticals, food and beverage, cosmetics, and water treatment industries.

Can a concave disc impeller handle high-viscosity fluids?

Yes, concave disc impellers are ideal for handling low- to medium-viscosity fluids and are effective in suspending solids and creating homogenous mixtures.

What is the advantage of the concave blade design?

The concave blade design improves mixing efficiency by creating a more powerful vortex, ensuring uniform blending and better particle suspension.

Are SV Industries’ concave disc impellers customizable?

Yes, we offer customized concave disc impellers with different blade configurations, materials, and sizes to meet your specific mixing requirements.

How energy efficient are concave disc impellers?

Concave disc impellers are energy-efficient, as they operate at moderate speeds, reducing power consumption while maintaining effective mixing performance.

What maintenance is required for concave disc impellers?

Concave disc impellers require minimal maintenance. Regular inspection and cleaning are recommended to ensure optimal performance.

How do I order a concave disc impeller from SV Industries?

Contact our sales team to discuss your specific requirements, and we will provide you with a customized impeller solution tailored to your needs.