Vessel Volume & Level Calculation

Vessel volume & level calculation ensures that every millimetre of liquid height converts into an accurate capacity value—across vertical and horizontal tanks. SV Industries provides a practical, engineer-friendly approach so your operators get trustworthy inventory numbers, faster batches, and cleaner audits.

🎯 What this covers

Works for common head geometries: ellipsoidal (2:1), hemispherical, torispherical (ASME F&D / standard / 0.8:0.1), and flat.

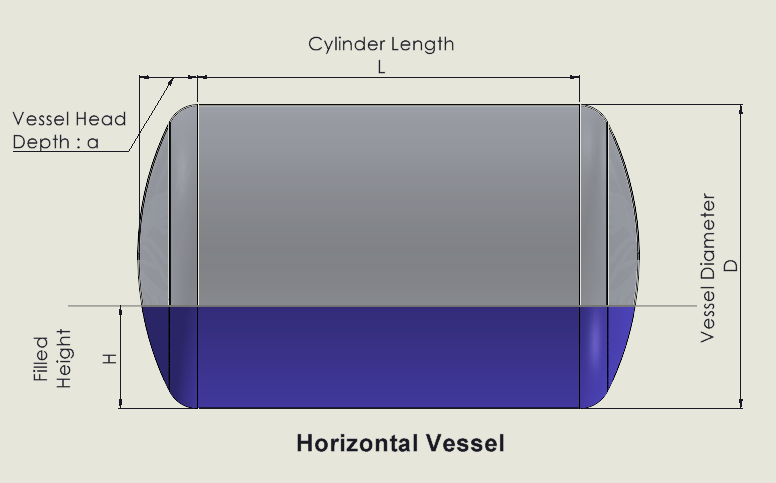

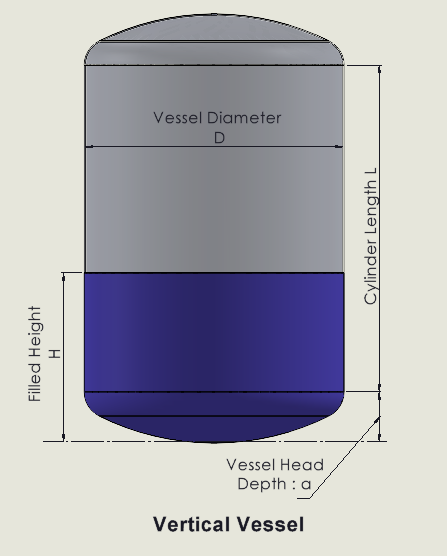

Handles both orientations with correct level reference: vertical (from bottom apex) and horizontal (0…D).

Unit flexibility: mm, m, inch—with consistent conversions.

vessel volume & level calculation

Inputs

Bottom head

Top head

Live visual preview

Results

| Level % | Level (unit) | Volume (m³) | Volume (L) | Volume (gal, US) |

|---|

Quick Start (2-minute Guide)

Follow these fast steps to get accurate level → volume in minutes. No CAD, no spreadsheets—just enter your geometry and download the calibration.

- 🧭 Choose Orientation

Select Vertical (H measured from bottom apex) or Horizontal (H ranges 0…D).

Tip: Horizontal tanks: 10% level = 0.1 × D (e.g., D=1000 → 100 mm). - 📐 Set Units

Pick mm, m, or inch. The calculator converts consistently—no rounding surprises across results. - ⌀ Enter Internal Dimensions

- Diameter (D) — internal only

- Straight length/height (L) — shell length excluding heads

If you’re sizing a new build, see our vessel options: Reactor Vessel or SS Jacketed Vessel.

- 🧩 Select Bottom & Top Head Types

Choose from Ellipsoidal (2:1), Hemispherical, Torispherical (ASME F&D / Standard / 0.8/0.1), or Flat.

Note: Head geometry affects dish depth and total capacity—match your fabrication drawing. - 📏 Enter Filled Level (H)

- Vertical: H from the bottom apex upward.

- Horizontal: H from lowest point; valid range 0…D.

- 🔁 Pick Calibration Step

Select 5% or 10% to generate a clean Level–Volume table suitable for SOPs and ERP upload. - ▶️ Review Live Visual & Results

The preview shows liquid fill (SV brand color), while outputs display Filled Volume, Total Volume, and a Level–Volume chart.

Need custom validation for your tank? Contact Us. - ⬇️ Export

- CSV for spreadsheets/ERP

- Print/PDF for QA files and audits

Want examples? Browse our latest posts in the Blog.

Pro tip: Mixing or heat-transfer constraints in real plants (coils, jackets, baffles) can change effective working capacity. Explore Limpet Coil Reactors to align calculation with actual process hardware.

Supported Head Types

Right head selection = right capacity. Our calculator models the most-used geometries exactly—so your level-to-volume stays reliable across builds and standards.

| Head Type | Depth (a) | Geometry / Parameters | Typical Use | Why it helps | Explore |

|---|---|---|---|---|---|

| Ellipsoidal (2:1) | a = D / 4 |

2:1 ellipse; R/r not required | Reactors, jacketed vessels | Balanced capacity without excessive height; good for agitator clearances | Reactor Vessel · SS Jacketed |

| Hemispherical (“Spherical” Head) | a = D / 2 |

Half-sphere cap; R/r not required | Higher pressure / thermal cycling | Best stress distribution; maximizes end-cap volume | Process Reactor |

| Torispherical (ASME F&D) f=1 · k=0.06 |

R = f·D = Dr = k·D = 0.06Da = R − √((R−r)² − (A−r)²), A=D/2

|

Crown + knuckle per ASME | Industry default for many vessels | Predictable fabrication; balanced height & capacity | Reactor Vessel |

| Torispherical (Standard F&D) f=1 · k=0.1 |

R = Dr = 0.1Da as per formula above

|

Gentler knuckle radius | Hygiene + fabrication friendly | Smoother transitions may improve local stresses & cleanability | SS Jacketed |

| Torispherical (F&D) f=0.8 · k=0.1 |

R = 0.8Dr = 0.1Da increases due to tighter crown

|

Designs needing deeper dish | Modifies end-volume & headroom; model captures exact change | Industrial Reactor | |

| Flat | a = 0 |

Flat plate; R/r not applicable | Atmospheric/low-pressure, removable covers | Simple fabrication; lowest added head volume | Products |

Vertical vs Horizontal — Level Reference

Reference point: bottom head apex (deepest internal point).

Htotal = abottom + L + atop (dish depths + straight length; all values are internal).

- 0 ≤ H ≤ abottom — filling the bottom head.

- abottom < H ≤ abottom + L — cylindrical shell region.

- abottom + L < H ≤ Htotal — top head (complement).

Sight-glass or transmitter zero should align with the apex datum to avoid offset errors.

Considering a new build? Explore Reactor Vessels and SS Jacketed Vessels.

Reference point: the lowest internal point of the shell.

Valid H range: 0 … D (diameter). Example: if D = 1000 mm, then 10% level = 100 mm.

- H = 0 — empty; H = D/2 — ~50% cylinder area (heads added via integration).

- H = D — full (cylinder + both heads at full).

- Transmitter “0%” at the drain datum; “100%” at top-of-ID. Record actual D during commissioning.

Validation & Sample Cases

- Inputs: D = 1000 mm, L = 2000 mm; Bottom head = Top head = Torispherical (ASME F&D, f=1, k=0.06)

- Expected dish depth (each): a ≈ 169.34 mm

- Total level range: Htotal = abottom + L + atop ≈ 2338.68 mm

- Total volume: ≈ 1.7328 m³ (±0.2%)

- Sanity: 100% level ≈ 2338.7 mm; total volume matches.

Inputs: D = 1000 mm, L = 2000 mm; Left/Right heads = Flat

Cylinder volume (exact): A = D/2 = 500 mm → Vcyl = π·A²·L = π·500²·2000 mm³ ≈ 1.570796 m³

| Level H (mm) | Expectation | Volume (m³) |

|---|---|---|

| 0 | Empty | 0 |

| 500 (D/2) | ~Half cylinder area | ≈ 0.785398 |

| 1000 (D) | Full cylinder | ≈ 1.570796 |

- Inputs: D = 1000 mm, L = 2000 mm; Bottom/Top = Hemispherical

- Dish depth (each): a = D/2 = 500 mm

- Per-head volume (exact): Vhead = (2/3)·π·A³ = (2/3)·π·500³ mm³ ≈ 0.261799 m³

- Total volume: V ≈ Vcyl + 2Vhead ≈ 1.570796 + 0.523599 = 2.094395 m³

- Total level range: Htotal = 500 + 2000 + 500 = 3000 mm

- Level datums: Vertical → bottom apex; Horizontal → 0…D (lowest to highest internal point).

- Units & rounding: Keep all inputs in one unit; export CSV and verify with your ERP sheet.

- Head selection: Match fabrication drawing (ASME F&D vs Standard vs 0.8/0.1) to avoid skew.

- Visual preview: Shape & meniscus should reflect orientation/heads; compare with vessel photos in the Gallary.

Need validation against P&IDs or as-built drawings? We can align calibration to your Reactor Vessel or SS Jacketed Vessel and provide signed QA PDFs — Contact Us.

Frequently Asked Questions (FAQs)

How do I calculate vessel volume from liquid level?

Enter internal Diameter (D), straight Length/Height (L), select head types for both ends, choose orientation, and input level (H). The calculator converts H → Volume instantly.

Should I use internal diameter (ID) or external diameter (OD)?

Use internal dimensions only.

Which head type should I select if drawings aren’t clear?

If unknown, ASME F&D (f=1, k=0.06) is a practical default in many plants.

Do jackets or limpet coils change the capacity?

External jackets do not change internal volume; limpet coils usually don’t either unless they intrude inside.

Does the agitator (anchor, PBT, hydrofoil) affect level-to-volume?

If the agitator/shaft/baffles intrude inside, they reduce capacity slightly.

The tank is slightly tilted—will calibration be wrong?

Yes, even small slope/tilt shifts the level-to-volume curve.

Can I mix different head types on top and bottom (or left/right)?

Yes—select per-end head types.