Industrial Chemical Reactor Manufacturer – SV Industries

At SV Industries, we are a trusted industrial chemical reactor manufacturer and supplier in India, delivering precision-engineered solutions for diverse processing industries. With decades of expertise and a state-of-the-art fabrication unit, we specialize in designing reactor vessels that ensure superior performance, safety, and reliability.

An Industrial Chemical Reactor is the heart of every chemical process plant. It facilitates controlled reactions by maintaining optimal temperature, pressure, mixing, and residence time, ensuring consistent product quality and process efficiency. At SV Industries, our reactor design focuses on maximizing productivity while reducing operational costs.

🔹 Why Choose SV Industries as Your Industrial Chemical Reactor Partner?

Tailored Reactor Designs – We manufacture customized solutions including limpet coil reactors and SS jacketed vessels to meet specific process requirements.

Versatile Applications – From pharmaceuticals to petrochemicals, our reactors are suitable for a wide range of industrial applications.

Reliable Construction – Built using premium-grade SS304, SS316, and special alloys for corrosion resistance and long-term durability.

Advanced Mixing Solutions – Compatible with multiple impeller designs including anchor impellers, helical impellers, paddle impellers, pitch blade turbines, and Rushton turbines.

Trusted Industry Reputation – Recognized as one of the best agitator manufacturers in India, serving clients across India and overseas.

🌍 Industry Relevance & Customer Value

Our reactors are engineered as value-driven solutions, not just equipment. They help industries enhance efficiency, scale production, and ensure safe operations. Whether you need a reactor vessel manufacturer in India or advanced industrial stirrer solutions, SV Industries delivers innovation with reliability.

Explore our full product range including agitators, storage tanks, and specialized industrial reactors on our products page.

Overview: What is an Industrial Chemical Reactor?

An Industrial Chemical Reactor is a specially designed vessel used to carry out chemical reactions under controlled conditions of temperature, pressure, mixing, and time. It is the core equipment of chemical processing plants, enabling industries to safely and efficiently convert raw materials into finished products such as pharmaceuticals, petrochemicals, polymers, and specialty chemicals.

In simple terms, it is the place where raw materials are transformed into valuable products through chemical reactions.

🔹 Key Characteristics of Industrial Chemical Reactors

Precise Reaction Control – Maintain required heat, pressure, and mixing.

Durable Construction – Manufactured from stainless steel (SS304/SS316) and special alloys.

Heating & Cooling Options – Limpet coil reactors and SS jacketed vessels for thermal regulation.

Efficient Mixing – Equipped with agitators and impellers like anchor impellers, paddle impellers, helical impellers, and Rushton turbines.

Process Flexibility – Suitable for batch, semi-batch, and continuous operations.

🌍 Why Are Industrial Chemical Reactors Essential?

Enable safe handling of high-temperature and high-pressure reactions.

Support scalable production, from pilot to full-scale plants.

Ensure uniform product quality with consistent reaction control.

Improve energy efficiency and sustainability with advanced reactor designs.

At SV Industries, we specialize in manufacturing reactor vessels that meet global standards, ensuring durability, precision, and reliability for every industrial application.

How Does an Industrial Chemical Reactor Work?

An Industrial Chemical Reactor works by providing a controlled environment where raw materials undergo chemical reactions under specific conditions of temperature, pressure, mixing, and reaction time. This ensures safe, efficient, and scalable production of chemicals, pharmaceuticals, and other industrial products.

🔹 Working Principle

An Industrial Chemical Reactor functions as the central processing unit of a chemical plant. The basic working involves four key steps:

- Raw Material Feeding – Reactants are introduced into the reactor vessel.

- Mixing & Agitation – Advanced agitators and impellers such as anchor impellers, paddle impellers, or helical impellers ensure uniform distribution of reactants.

- Heating & Cooling – Systems like limpet coil reactors and SS jacketed vessels maintain the required temperature for optimal reactions.

- Reaction Control – By regulating pressure, time, and energy input, desired products are formed with consistency and efficiency.

🔹 Types of Reaction Modes

- Batch Mode – Small-scale or specialty production where reactants are processed in fixed quantities.

- Continuous Mode – Large-scale manufacturing where reactants are continuously fed and products are continuously removed.

- Semi-Batch Mode – A hybrid process suitable for reactions requiring precise feed control.

Design Features & Technical Specifications of Industrial Chemical Reactors

Every Industrial Chemical Reactor manufactured by SV Industries is engineered with precision to deliver safety, durability, and performance. Our reactors are designed according to international standards, making them suitable for industries like pharmaceuticals, chemicals, petrochemicals, and food processing.

🔹 Key Design Features

- High-Grade Construction: Built with SS304, SS316, or specialized alloys for superior corrosion resistance and long service life.

- Heating & Cooling Systems: Options like limpet coil reactors and SS jacketed vessels to regulate temperature efficiently.

- Mixing Excellence: Integrated with advanced agitators and impellers such as pitch blade turbines, anchor impellers, helical impellers, and paddle impellers.

- Pressure & Vacuum Rating: Capable of handling atmospheric as well as high-pressure/high-vacuum operations.

- Automation Ready: Compatible with modern process control systems for precise monitoring.

- Customizable Design: Available in batch, semi-batch, and continuous configurations to suit diverse reactor applications.

🔹 Technical Specifications (Typical Range)

| Parameter | Typical Range / Options |

|---|---|

| Capacity | 50 L – 60,000 L (larger/custom on request) |

| Type of Operation | Batch / Semi-batch / Continuous |

| Material of Construction (MOC) | SS304, SS316/SS316L, Hastelloy C-276, MS with rubber/FRP/PTFE lining (as required) |

| Internal Surface Finish (Ra) | 0.8 – 0.4 μm Ra mechanical polish; electropolish optional (GMP) |

| External Surface Finish | 1.6 – 0.8 μm Ra matt / mirror; coated or brushed finish optional |

| Design Code / Standards | ASME Section VIII Div.1 / PED (where applicable) / cGMP guidelines |

| Documentation & Certifications | MTC, IQ/OQ (on request), calibration certificates, weld maps, FAT/SAT |

| Design Pressure – Shell | Full vacuum to 15 bar(g) (higher on request) |

| Design Pressure – Jacket/Coil | Up to 10 bar(g) steam/hot oil; customized per utility |

| Design Temperature – Shell | −20°C to +300°C (MOC dependent) |

| Design Temperature – Jacket/Coil | −20°C to +200°C (medium dependent) |

| Corrosion Allowance | 1.5 – 3.0 mm (service dependent) |

| Nozzles & Connections | ANSI/ASME B16.5 flanges, tri-clamp hygienic ferrules, DIN on request |

| Agitator Type | Anchor / Helical / Pitch Blade Turbine / Rushton / Hydrofoil / Custom hybrid |

| Agitator Speed Range | 10 – 300 RPM with VFD (higher for small volumes) |

| Drive Type | Helical gear reducer with TEFC motor; inline/outboard bearing design |

| Motor Power | 0.75 – 45 kW (duty & viscosity based sizing) |

| Mechanical Seal / Gland | Single/double mechanical seal (cartridge) or stuffing box; ATEX on request |

| Baffles | 2–4 anti-swirl baffles; removable sanitary baffles optional |

| Heating / Cooling Medium | Steam, hot oil/thermal fluid, chilled water, brine, glycol |

| Heat Transfer Area (typ.) | Jacket: ~0.8 – 45 m²; Limpet coil: ~1 – 60 m² (capacity dependent) |

| Insulation & Cladding | 50–100 mm mineral wool/PUF; SS sheet or aluminum cladding |

| Instrumentation | PT-100/RTD, pressure gauge/transmitter, sight glass/light, level (DP/float), rupture disc/safety valve |

| Surface Treatments / Linings | GLR, PTFE/PFA, rubber lining, passivation; pickling as standard |

| Testing & NDT | Hydro & pneumatic tests, DP/MP, radiography/UT (as per QC plan) |

| Utilities Required | Electrical: 3-phase 415 V; Compressed air: 5–6 bar; Steam/thermal fluid as per duty |

| Accessories | Manway, CIP/SIP spray ball, sampling valve, bottom discharge valve, thermowell, lifting lugs |

| Automation & Control | PLC/HMI or SCADA, recipe/batch reports, alarms/interlocks, load cell integration |

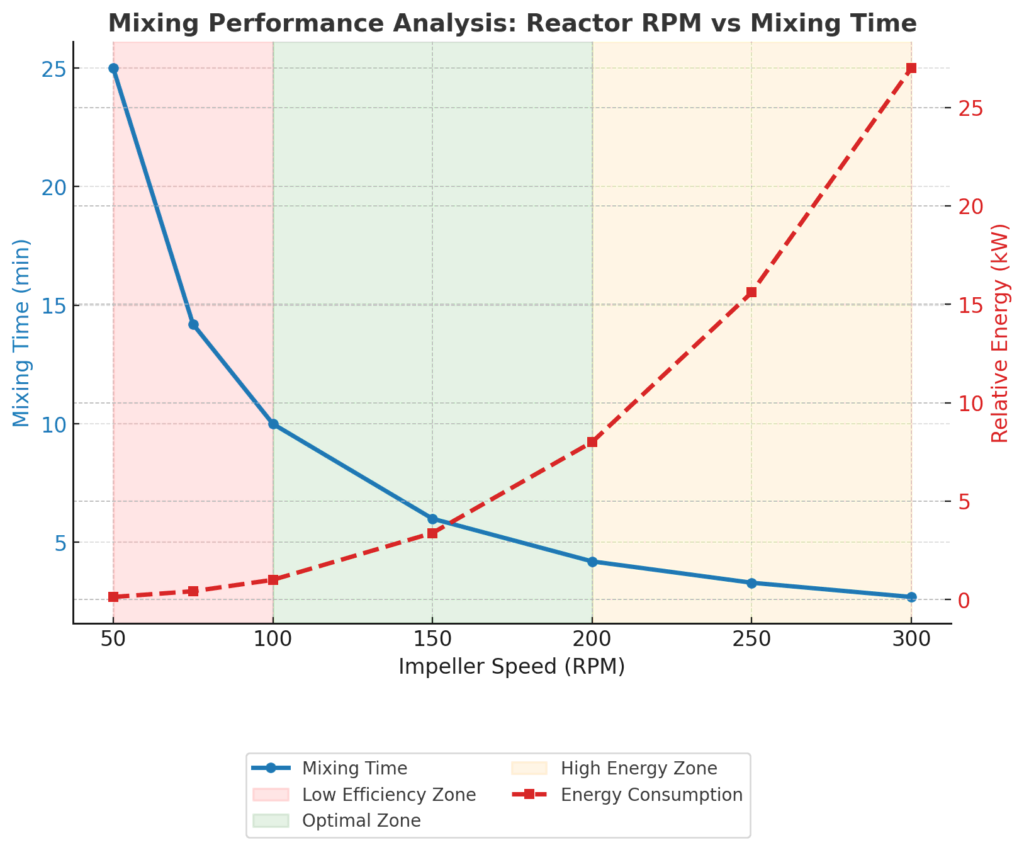

📊 Mixing Performance Analysis: Reactor RPM vs Mixing Time

Mixing performance is a critical factor in Industrial Chemical Reactors, directly affecting reaction efficiency, product consistency, and operational cost. The chart below illustrates how impeller speed (RPM) impacts both mixing time and energy consumption, helping engineers and buyers optimize reactor design for maximum performance.

💡 Analysis

The chart shows a clear trade-off: as RPM increases, mixing time drops from 25 minutes (at 50 RPM) to under 3 minutes (at 300 RPM). However, energy demand rises sharply — from 0.13 kW at 50 RPM to nearly 27 kW at 300 RPM.

- 🔴 Low RPM → Poor mixing, slow processes

- 🟢 Optimal range (100–200 RPM) → Balanced efficiency with controlled energy cost

- 🟠 High RPM → Fast mixing but costly in terms of power

At SV Industries, we ensure the best balance between speed and efficiency by selecting the right impeller system (such as Anchor Impeller, Pitch Blade Turbine, or Rushton Turbine) and optimizing RPM settings. This guarantees energy-efficient, high-performance mixing tailored to your process requirements.

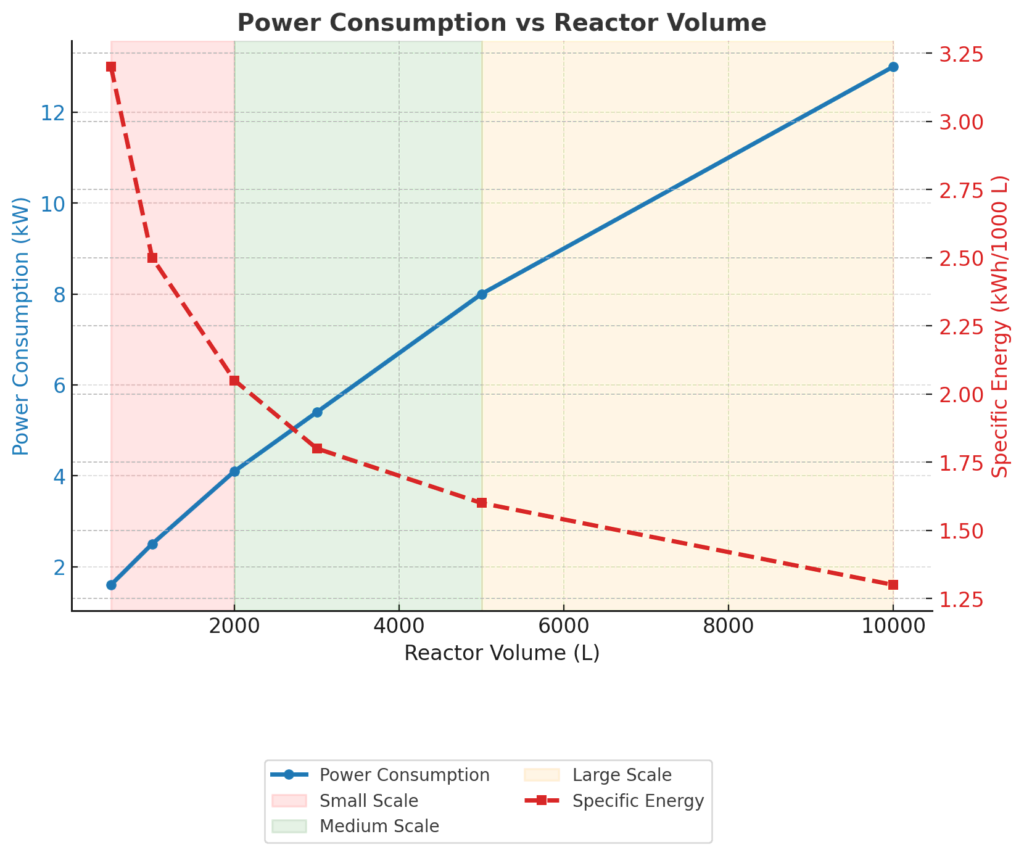

📊 Power Consumption vs Reactor Volume

Power consumption is one of the most important considerations in Industrial Chemical Reactors since it directly impacts operational cost, energy efficiency, and scalability. The chart below compares reactor volume vs power consumption, showing how larger volumes achieve economies of scale in chemical processing.

💡 Analysis

The analysis clearly shows that while total power demand increases with reactor size (from 1.6 kW at 500 L to 13 kW at 10,000 L), the specific energy per 1000 L decreases significantly (from 3.2 kWh to 1.3 kWh).

- 🔴 Small reactors → Higher energy usage per unit volume

- 🟢 Medium reactors → Optimal balance between energy cost and productivity

- 🟠 Large reactors → Most efficient for bulk production

At SV Industries, we design reactors with optimized agitator systems and energy-efficient impellers (such as Pitch Blade Turbine, Hydrofoil Impeller, and Anchor Impeller) to minimize power consumption while ensuring high-performance mixing and reaction efficiency.

Customization Options for Industrial Reactors

Industrial chemical reactors can be customized based on process requirements, raw materials, mixing needs, and industry standards. At SV Industries, we specialize in tailoring each reactor’s design, material, capacity, and agitation system to meet client-specific applications, ensuring maximum efficiency and reliability.

⚙️ Key Customization Areas

- Reactor Design: Choose from jacketed reactors, limpet coil reactors, pressure vessels, and glass-lined options depending on thermal and process demands.

- Material of Construction (MOC): Available in Mild Steel, SS 304, SS 316, Hastelloy, Alloy steels, and other corrosion-resistant materials for handling diverse chemicals.

- Agitation System: Custom impeller designs such as Anchor Impeller, Pitch Blade Turbine, Rushton Turbine, Hydrofoil Impeller, and Paddle Impeller are integrated for optimized mixing.

- Capacity Range: From 100 liters to 100,000 liters, tailored to match batch size and production scale.

- Pressure & Temperature Ratings: Reactors can be designed to handle vacuum to high pressure (up to 50 bar) and temperatures up to 300°C.

- Heating & Cooling Options:

- SS Jacketed Vessels for efficient thermal transfer

- Limpet Coil Reactors for uniform heating/cooling cycles

- Automation & Controls: Integration of digital control panels, PLC automation, and temperature/pressure monitoring systems for modern process industries.

📊 Typical Customization Parameters

| Parameter | Customization Range | Options Available |

|---|---|---|

| Capacity | 100 L – 100,000 L | Lab-scale, Pilot, Industrial |

| Material of Construction | M.S., SS 304, SS 316, Hastelloy | Corrosion-resistant options |

| Agitation System | 50 – 500 RPM | Anchor, PBT, Hydrofoil, Rushton |

| Pressure Rating | Vacuum to 50 bar | Atmospheric, Pressurized |

| Temperature | -20°C to 300°C | With cooling/heating jackets |

| Surface Finish | Mirror Polish / Matt | Hygienic grade for Pharma & Food |

💡 Why Choose SV Industries for Reactor Customization?

- Decades of expertise as a trusted reactor vessel manufacturer in India.

- Flexible customization ensuring compliance with pharma, chemical, petrochemical, and food industry standards.

- In-house design, fabrication, and rigorous quality testing for long-lasting performance.

- Full support from design consultation to after-sales service.

🌍 Applications Where Customization Matters

- Pharmaceuticals → Sterile & hygienic reactors for sensitive formulations

- Specialty Chemicals → Corrosion-resistant vessels for aggressive solvents

- Food & Beverages → Hygienic-grade mixing systems for safe processing

- Petrochemicals & Polymers → High-pressure, high-temperature designs for bulk production

📞 Ready to discuss your process needs? Get in touch with us today via our Contact Page or explore our Gallery for reactor manufacturing excellence.

Industrial Applications of Chemical Reactors

Industrial chemical reactors are widely used in pharmaceuticals, chemicals, petrochemicals, food processing, and environmental industries to carry out controlled chemical reactions safely and efficiently. A well-designed reactor ensures optimum yield, precise temperature and pressure control, and scalability from lab-scale to bulk production.

⚙️ Key Industries Using Chemical Reactors

- Pharmaceutical Industry:

Used for synthesizing APIs (Active Pharmaceutical Ingredients), fermentation, and sterile liquid formulations where hygienic reactor design is critical. - Chemical & Specialty Chemicals:

For producing dyes, paints, resins, adhesives, and catalysts, where reactors with corrosion-resistant materials like SS 316 or Hastelloy are preferred. - Petrochemicals & Polymers:

Essential for polymerization, cracking, blending, and refining operations. High-pressure Reactor Vessels ensure safe performance in these applications. - Food & Beverage Industry:

Jacketed and limpet coil SS vessels are used for brewing, flavoring, emulsification, and other food-grade processes. - Water & Wastewater Treatment:

Custom Industrial Stirrer and reactors help in neutralization, aeration, and biological treatment in ETP/STP applications. - Agrochemicals & Fertilizers:

Designed for large-scale reaction processes involving strong acids, alkalis, and solvents.

📊 Industry-Reactor Mapping

| Industry | Typical Reactor Type | Key Requirements |

|---|---|---|

| Pharmaceuticals | SS Jacketed, Glass-Lined | Sterility, CIP/SIP systems |

| Chemicals | Limpet Coil, Pressure Reactors | Corrosion resistance, Heat transfer |

| Petrochemicals | High-Pressure Reactors | Durability, High-temperature endurance |

| Food & Beverages | SS 304 / SS 316 Reactors | Hygienic design, Easy cleaning |

| Water Treatment | Agitated Reactors | Efficient mixing, Durability |

📞 Partner with SV Industries

As a trusted chemical reactor manufacturer, SV Industries delivers process-specific reactor solutions to global clients. Whether you need lab-scale R&D reactors or bulk production vessels, our team ensures precision design, robust construction, and world-class performance.

👉 Explore our Gallery for real manufacturing projects or Contact Us to discuss your industry’s requirements.

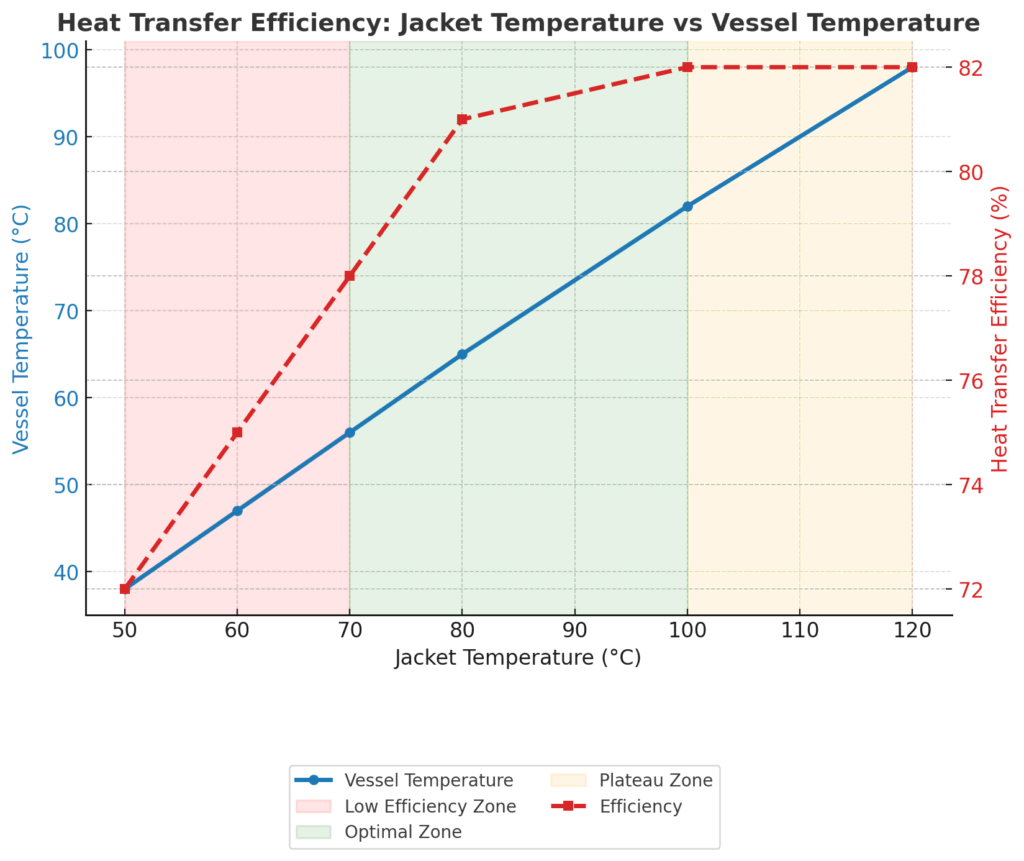

📊 Heat Transfer Efficiency: Jacket Temperature vs Vessel Temperature

Heat transfer performance is a vital parameter in Industrial Chemical Reactors, especially for processes that require precise temperature control. The chart below demonstrates how jacket temperature impacts vessel temperature and overall heat transfer efficiency, guiding buyers in selecting the right reactor design for their thermal needs.

💡 Analysis

As the chart shows, increasing the jacket temperature from 50°C to 100°C raises the vessel liquid temperature significantly (from 38°C to 82°C) with improved efficiency. However, beyond 100°C, the efficiency curve flattens (~82%), meaning additional heating offers minimal benefit.

- 🔴 Low range → Poor efficiency, longer heating times

- 🟢 Optimal range → Maximum heat transfer per energy input

- 🟠 Plateau range → Wasted energy with little added benefit

At SV Industries, we design SS Jacketed Vessels and Limpet Coil Reactors with optimized jacket design, surface area, and agitation systems to ensure fast, uniform, and energy-efficient heating & cooling.

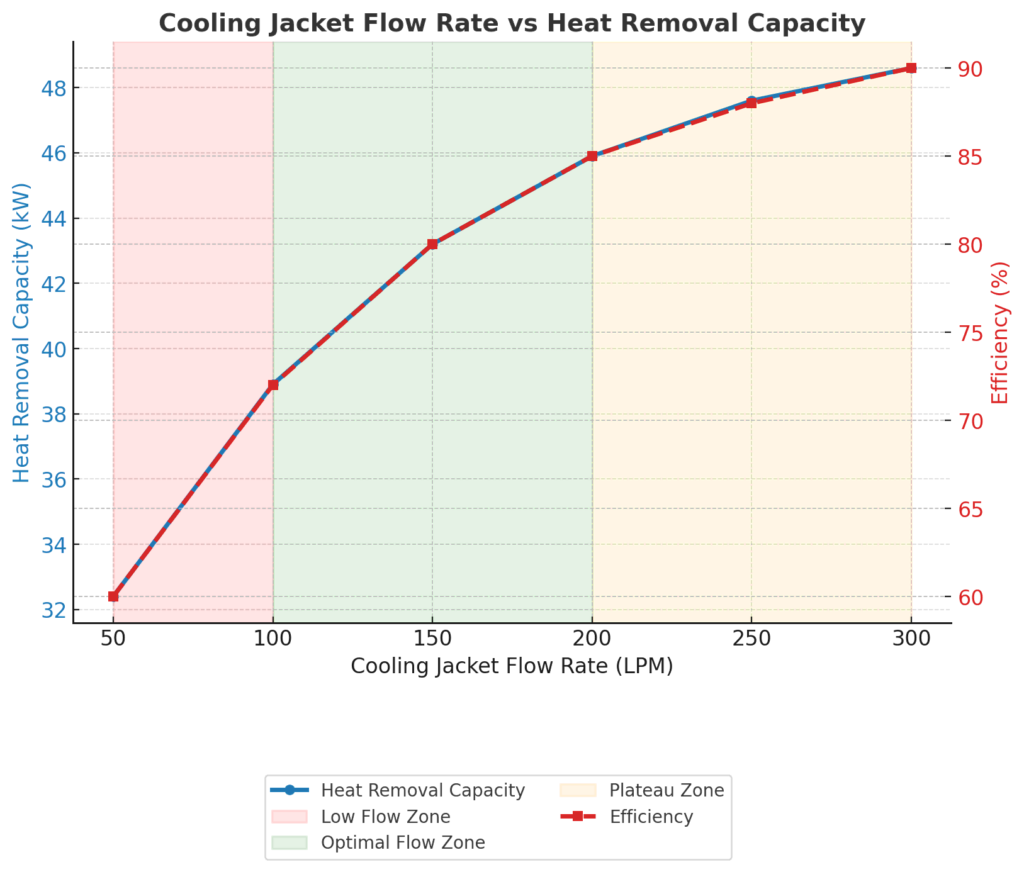

📊 Cooling Jacket Flow Rate vs Heat Removal Capacity

In Industrial Chemical Reactors, cooling efficiency is crucial to maintain safe operation and prevent runaway reactions. The chart below illustrates how jacket flow rate affects heat removal capacity, guiding engineers to select the right cooling configuration for stable reactor performance.

💡 Analysis

The results show that increasing jacket flow from 50 LPM to 200 LPM boosts heat removal capacity from 32 kW to nearly 46 kW, improving efficiency from 60% to 85%. Beyond 200 LPM, the efficiency gain slows, proving that very high flow rates don’t significantly enhance cooling.

- 🔴 Low flow → Poor heat transfer, unstable operation risk

- 🟢 Optimal flow (100–200 LPM) → Maximum efficiency for chemical & pharma processes

- 🟠 High flow (>200 LPM) → Higher pumping cost with minimal benefit

At SV Industries, we design SS Jacketed Vessels and Limpet Coil Reactors with optimized jacket geometry and flow control. This ensures efficient heat removal, reducing energy waste while maintaining safe, reliable reactor operations.

Advantages of Choosing SV Industries Industrial Chemical Reactors

SV Industries stands out as a trusted chemical reactor manufacturer and industrial reactor supplier because of our focus on customized design, premium quality materials, and process-specific engineering. Our reactors are built to deliver high efficiency, durability, and compliance with global industry standards—making them the preferred choice for businesses across pharmaceuticals, chemicals, petrochemicals, and more.

⚙️ Key Advantages

- Tailor-Made Reactor Design: Every reactor is engineered based on process needs, capacity, and reaction type to ensure maximum efficiency.

- Superior Material Selection: Options in SS 304, SS 316, Hastelloy, Mild Steel, and Alloy Steels for excellent corrosion resistance and longevity.

- Advanced Mixing Solutions: Integration of high-performance impellers such as Anchor Impeller, Pitch Blade Turbine, Rushton Turbine, Hydrofoil Impeller, and Paddle Impeller for process-specific mixing.

- Thermal Efficiency: Options of SS Jacketed Vessels and Limpet Coil Reactors for efficient heating and cooling cycles.

- Safety & Compliance: Designed to handle vacuum to high-pressure conditions with precise temperature control up to 300°C, meeting ASME & GMP standards.

- Scalability: From pilot-scale chemical process reactors to large industrial reactors, supporting growth from R&D to mass production.

- Proven Reliability: Heavy-duty construction ensures minimum downtime, longer service life, and low maintenance costs.

📊 Advantages at a Glance

| Feature | Benefit for Buyers |

|---|---|

| Custom Design | Process-optimized reactor efficiency |

| Material Options | Durability & corrosion resistance |

| Impeller Variety | Better mixing & uniform reactions |

| Thermal Systems | Precise heating/cooling control |

| Pressure & Temperature Range | Safe operation under critical conditions |

| Scalability | From R&D to bulk production |

🌍 Why Buyers Trust SV Industries

- End-to-end solutions from reactor vessel design to after-sales support.

- Transparent processes with in-house fabrication & strict quality checks.

- Serving industries globally with proven expertise as a Reactor Vessel Manufacturer in India.

- Backed by decades of experience and continuous innovation in chemical process reactors.

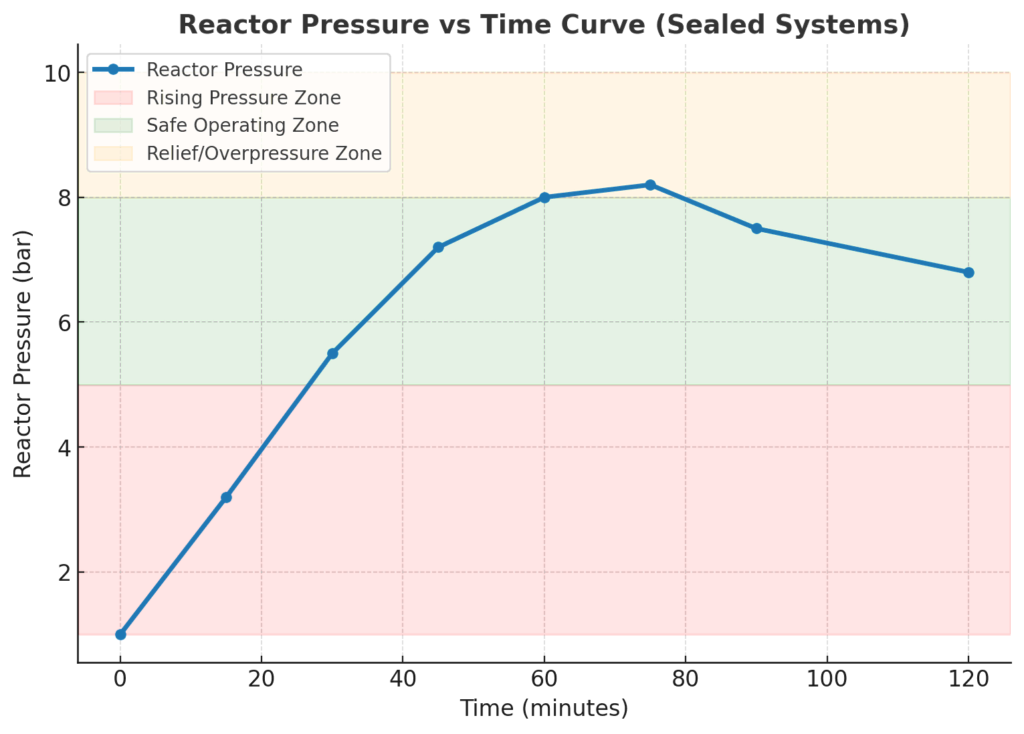

📊 Reactor Pressure vs Time Curve (for Sealed Systems)

In sealed chemical reactors, pressure buildup is a critical parameter that must be closely monitored for safety and process stability. The chart below shows a typical Reactor Pressure vs Time Curve, highlighting how sealed systems behave during exothermic reactions and why pressure relief mechanisms are essential.

💡 Analysis

The chart demonstrates that reactor pressure rises from 1 bar at start-up to nearly 8 bar within 60 minutes, at which point the safety relief valve opens to prevent overpressure.

- 🔴 Initial zone → Rapid pressure buildup due to reaction kinetics

- 🟢 Safe zone (5–8 bar) → Stable operation for most industrial processes

- 🟠 Relief zone → Ensures system integrity and operator safety

At SV Industries, all Reactor Vessels and Industrial Chemical Reactors are designed with robust pressure ratings, relief valves, and compliance to ASME & GMP standards. This guarantees not only efficient performance but also unmatched safety assurance for critical chemical processes.

Material Compatibility & Safety Assurance

Material compatibility ensures that an Industrial Chemical Reactor can safely handle corrosive chemicals, high pressure, and extreme temperatures without compromising performance or operator safety. At SV Industries, every reactor is designed with the right material of construction (MOC) to guarantee durability, corrosion resistance, and safe operation in demanding industrial environments.

⚙️ Material Options for Chemical Reactors

- Mild Steel (MS): Cost-effective choice for general-purpose chemical processes.

- Stainless Steel 304 (SS 304): Suitable for food-grade and low-to-moderate corrosive applications.

- Stainless Steel 316 (SS 316): Enhanced resistance to strong acids, alkalis, and solvents; widely used in chemical process reactors.

- Hastelloy & Exotic Alloys: Designed for highly corrosive and high-temperature chemical reactions.

📊 Material Compatibility Chart

| Chemical / Process | MS | SS 304 | SS 316 | Hastelloy |

|---|---|---|---|---|

| Water / Neutral Liquids | ✔️ | ✔️ | ✔️ | ✔️ |

| Acids (Mild) | ⚠️ Limited | ✔️ | ✔️ | ✔️ |

| Strong Acids (HCl, H₂SO₄) | ❌ | ⚠️ Partial | ✔️ | ✔️ Best |

| Alkaline Solutions | ⚠️ Limited | ✔️ | ✔️ | ✔️ |

| High-Temperature Solvents | ❌ | ⚠️ Limited | ✔️ | ✔️ Best |

| Food & Pharma Applications | ❌ | ✔️ | ✔️ | ✔️ |

💡 Safety Assurance with SV Industries

- Pressure Tested Reactors: Designed for vacuum to 50 bar pressure applications.

- Thermal Safety: Operates efficiently from -20°C to 300°C with advanced SS Jacketed Vessels and Limpet Coil Reactors.

- Regulatory Compliance: Built to meet ASME, GMP, and international quality standards.

- Operator Safety: Advanced sealing systems, overpressure protection, and automation reduce risk during critical operations.

Technical Resources: Performance Analysis

Performance analysis evaluates how effectively an Industrial Chemical Reactor converts raw materials into desired products under controlled operating conditions. It focuses on parameters like conversion efficiency, mixing performance, heat transfer, and energy consumption. At SV Industries, we provide detailed technical resources and engineering insights to help buyers understand reactor performance before making an investment.

⚙️ Key Performance Metrics

- Conversion Efficiency (%) → Measures how much of the reactant is transformed into the final product.

- Residence Time Distribution (RTD): Evaluates flow pattern inside the reactor, ensuring uniform mixing.

- Heat Transfer Rate: Indicates how efficiently the reactor maintains optimal reaction temperature.

- Energy Consumption: Determines overall cost-effectiveness of the process.

- Agitation Efficiency: Based on impeller design such as Anchor Impeller, Rushton Turbine, Pitch Blade Turbine, and Hydrofoil Impeller.

📊 Example Performance Data

| Parameter | Typical Range | Impact on Process |

|---|---|---|

| Conversion Efficiency | 85 – 98% | Higher yield, reduced raw material loss |

| Residence Time | 10 – 60 min (depending on design) | Controls reaction selectivity & purity |

| Heat Transfer Coefficient | 200 – 800 W/m²·K | Efficient cooling/heating cycles |

| Energy Consumption | 0.2 – 1.5 kWh/kg | Directly affects operating cost |

| Agitation Speed | 50 – 500 RPM | Uniform mixing & better reaction rates |

💡 How SV Industries Ensures Superior Performance

- Design Optimization: Advanced Reactor Design tools to simulate flow and heat transfer.

- Customized Agitation: Impeller selection based on fluid rheology and process type.

- Material Engineering: Choosing the right SS Jacketed Vessel or Limpet Coil Reactor for consistent thermal stability.

- Energy-Efficient Solutions: Focus on reducing operational costs while ensuring consistent output.

- Testing & Validation: Each reactor undergoes rigorous hydrostatic tests, performance trials, and QA checks before dispatch.

🌍 Value for Buyers

- Get transparent technical data for informed decision-making.

- Compare performance with different reactor types (Batch, CSTR, PFR).

- Ensure safe, reliable, and cost-effective operations.

- Access expert consultation from a proven Reactor Vessel Manufacturer in India.

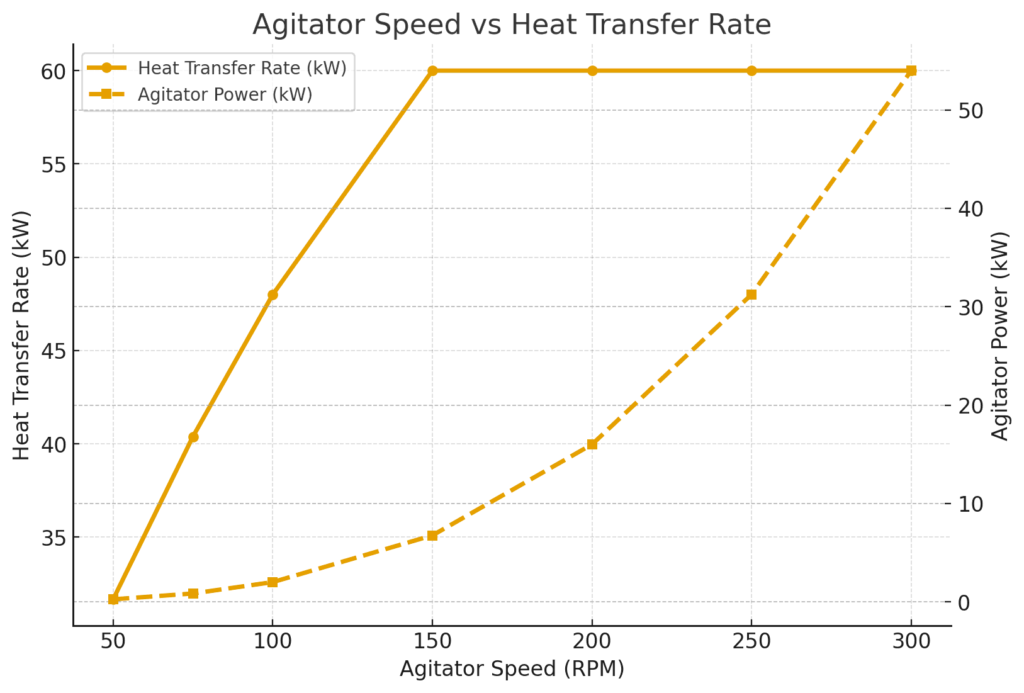

📊 Agitator Speed vs Heat Transfer Rate

Heat removal is critical in an Industrial Chemical Reactor to control reaction temperature and protect product quality. The chart compares agitator speed (RPM) with heat transfer rate and the shaft power required, helping engineers identify the most efficient reactor design and agitation setting.

💡 Analysis

Increasing RPM from 50 → 150 improves heat transfer from ~32 → 60 kW, but beyond ~150–200 RPM the curve plateaus, while agitator power continues to rise steeply (≈ 6.8 kW at 150 RPM to 54 kW at 300 RPM).

Optimal region: ~100–150 RPM for strong convection with controlled energy draw.

High RPM: minimal heat-transfer gain, significant energy penalty and potential shear issues.

SV Industries optimizes impeller selection (Anchor, PBT, Hydrofoil) and RPM to maximize heat transfer per kW, delivering energy-efficient solutions from a trusted chemical reactor manufacturer and industrial reactor supplier.

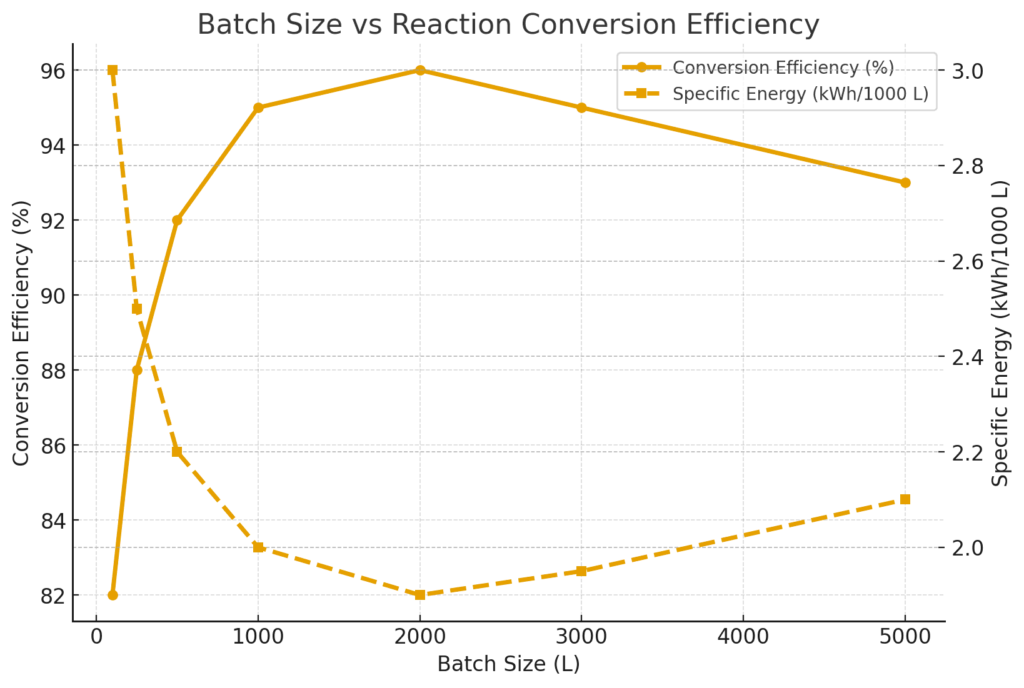

📊 Batch Size vs Reaction Conversion Efficiency

Batch sizing has a direct impact on reaction conversion, energy usage, and throughput in an Industrial Chemical Reactor. The chart maps batch volume vs conversion efficiency and the specific energy per 1000 L, helping buyers pick the most economical operating window for their process and reactor design.

💡 Analysis

Conversion climbs from 82% at 100 L to ~96% at 2000 L thanks to better thermal stability and residence time. Past ~2000 L, conversion plateaus and then slips slightly (93% at 5000 L) as mixing/heat-removal limits appear. Meanwhile, specific energy improves from 3.0 → ~1.9 kWh/1000 L, then levels off.

Implication: The sweet spot for this chemistry is around 1000–2000 L—high conversion with strong energy efficiency.

SV Industries tunes impeller selection, baffle layout, and jacket/coil sizing to keep conversion high even at larger volumes—backed by our experience as a trusted chemical reactor manufacturer and industrial reactor supplier.

SV Industries – Trusted Partner for Chemical Processing Solutions

Why partner with SV Industries for Industrial Chemical Reactors?

Because we don’t just supply equipment — we deliver end-to-end chemical processing solutions. As a leading chemical reactor manufacturer and reactor vessel supplier in India, SV Industries combines engineering expertise, premium-quality materials, and customer-focused services to help industries achieve operational excellence.

💡 What Sets Us Apart

- Comprehensive Product Range: From Industrial Chemical Reactors and Reactor Vessels to Agitators and Storage Tanks.

- Process-Specific Customization: Tailor-made solutions for pharma, chemical, petrochemical, food, and water treatment industries.

- Engineering Excellence: Use of advanced impeller systems like Anchor Impeller, Rushton Turbine, Paddle Impeller, and Hydrofoil Impeller.

- Global Standards Compliance: Designed as per ASME, GMP, and ISO standards, ensuring safety and long-term reliability.

- Proven Track Record: Trusted by industries across India and abroad with a reputation for precision manufacturing and timely delivery.

🌍 Value for Buyers

- One-stop partner for complete process equipment needs.

- Transparent manufacturing with real project showcases in our Gallery.

- Backed by expert consultation, after-sales support, and continuous innovation.

- Recognized among the best agitator manufacturers in India.

💡 How SV Industries Ensures Superior Performance

- One-stop partner for complete process equipment needs.

- Transparent manufacturing with real project showcases in our Gallery.

- Backed by expert consultation, after-sales support, and continuous innovation.

- Recognized among the best agitator manufacturers in India.

📞 Let’s Build Success Together

At SV Industries, we understand that every chemical process is unique. That’s why our focus is on engineering reactors that align perfectly with your production goals. Whether you need a pilot-scale R&D reactor or a bulk production vessel, we ensure the right balance of efficiency, safety, and cost-effectiveness.

👉 Explore our full Product Range, read our expert Blog, or Contact Us today to discuss your requirements.

Frequently Asked Questions (FAQs) about Industrial Chemical Reactors

What is an Industrial Chemical Reactor?

An Industrial Chemical Reactor is a specialized vessel designed to carry out chemical reactions under controlled conditions of temperature, pressure, and mixing. It ensures safe, efficient, and scalable production in industries such as pharma, chemicals, food, and petrochemicals.

What are the different types of Industrial Reactors?

The main types include:

Batch Reactors – For small-scale, flexible operations.

Continuous Stirred Tank Reactors (CSTRs) – For uniform mixing and continuous processes.

Plug Flow Reactors (PFRs) – For large-scale continuous reactions with high conversion.

Specialized Vessels like SS Jacketed Reactors

How much does an Industrial Chemical Reactor cost in India?

The cost of an Industrial Chemical Reactor depends on its capacity, material (SS 304, SS 316, Hastelloy, MS), and design type (jacketed, limpet coil, pressure). On average, prices range from ₹2.5 lakh for small reactors to ₹50+ lakh for large customized vessels.

Which is better: Jacketed Reactor or Limpet Coil Reactor?

A Jacketed Reactor is ideal for uniform heating/cooling in pharma & food industries, while a Limpet Coil Reactor is preferred for chemical and petrochemical applications requiring higher heat transfer efficiency. Both are available at SV Industries and can be customized.

How long is the lifespan of a chemical reactor?

With proper material selection, surface treatment, and maintenance, an SS 316 reactor can last 15–20 years, while MS reactors may last 8–10 years depending on chemical compatibility.

Can Industrial Chemical Reactors be customized?

Yes! At SV Industries, we offer fully customizable Industrial Chemical Reactors based on:

✔ Reactor Type & Design (Batch, Continuous, CSTR, PFR, etc.).

✔ Material of Construction (SS, Carbon Steel, Glass-Lined, Hastelloy).

✔ Heating & Cooling Options (Jacketed, Limpet Coil, Heat Exchangers).

✔ Agitation & Mixing Mechanism (Anchor, Turbine, Propeller Agitators).

✔ Automation & Control Systems (PLC, SCADA, Remote Monitoring).

We tailor our Industrial Chemical Reactors to meet specific industry requirements for maximum efficiency and performance.

What is the difference between Batch Reactor and Continuous Reactor?

Batch Reactors → Best for small-scale, flexible, and high-value processes like pharmaceuticals.

Continuous Reactors (CSTR/PFR) → Best for large-scale, high-output industries like petrochemicals and polymers.

Which impeller is best for Industrial Reactors?

The best impeller depends on fluid properties:

- Anchor Impeller → Viscous liquids

- Rushton Turbine → Gas-liquid reactions

- Pitch Blade Turbine → Solid suspension

- Hydrofoil Impeller → Energy-efficient mixing

Can one reactor be used for multiple chemical processes?

Yes, but only if designed with multi-purpose compatibility in terms of MOC, agitation, and thermal systems. Many industries prefer modular reactors for versatility.

How do I calculate reactor size for my plant?

Reactor size depends on batch volume, residence time, conversion efficiency, and mixing intensity. Our engineers provide detailed performance analysis & sizing calculations before manufacturing.

What safety features are included in SV Industries reactors?

Overpressure relief systems

Double mechanical seals for agitators

Hydrostatic testing for pressure integrity

Explosion-proof motors for agitators in hazardous areas