Paper Pulp Chest Agitator manufacturer in India

SV Industries designs and manufactures pulp chest agitators engineered for 2.5–5.0% consistency pulp, tank volumes from 200 L to 40 m³ (0.2–40 KL), and viscosities up to 800–1,200 cP, delivering uniform suspension, minimal flocculation, and low power per m³. Our designs cover top-entry pulp agitators with hydrofoil or pitched blades for reliable pumping at 25–120 RPM.

Plant heads and process engineers choose us when they need a pulp chest mixer that keeps fibers in suspension during storage, level variations, and starts/stops—without vertexing or air entrainment. As an experienced pulp chest agitator manufacturer, we tailor impeller geometry (hydrofoil, PBT) and motor kW to pulp SG ~1.0–1.1, chest geometry, and required turnover time. Explore our broader Agitator solutions or see our Hydrofoil Impeller guide for energy-efficient pumping (read the guide).

Share your viscosity, volume (L/KL), consistency % and tank dimensions—we’ll suggest impeller type, RPM & kW. Contact SV Industries.

What is a Pulp Chest Agitator?

A pulp chest agitator is a low-speed, high-flow mixer fitted to a pulp storage/surge chest to keep Fibers and fillers uniformly suspended with minimal shear. SV Industries supplies top-entry designs that run typically at 25–120 RPM and use motors from 1–55 kW depending on volume and consistency.

A pulp chest agitator’s primary purpose is suspension (not intensive dispersive mixing). It produces an axial flow pattern that sweeps the tank floor and returns along the surface, preventing settling, matting and air entrainment during level swings or transfers. Key selection drivers are pulp consistency (%), viscosity (cP), specific gravity (SG ~1.0–1.1), chest volume (L / m³ / KL) and desired turnover time.

How it works — concise steps:

- Motor → shaft → impeller (sealed or magnetic drive) transmits torque.

- Impeller (hydrofoil or pitched-blade) produces bulk axial flow and floor sweep.

- System target: full tank turnover in a set time (commonly 10–30 min) which sets required flow (Q) and motor kW.

- Power requirement rises with consistency and viscosity; impeller diameter and pitch tune lift and flow.

| Impeller | Best for | RPM | Advantage |

|---|---|---|---|

| Hydrofoil | Low energy, continuous suspension | 25–80 RPM | High flow per kW |

| Pitch Blade Turbine | Re-suspending settled fiber | 40–120 RPM | Stronger lift, less vortex |

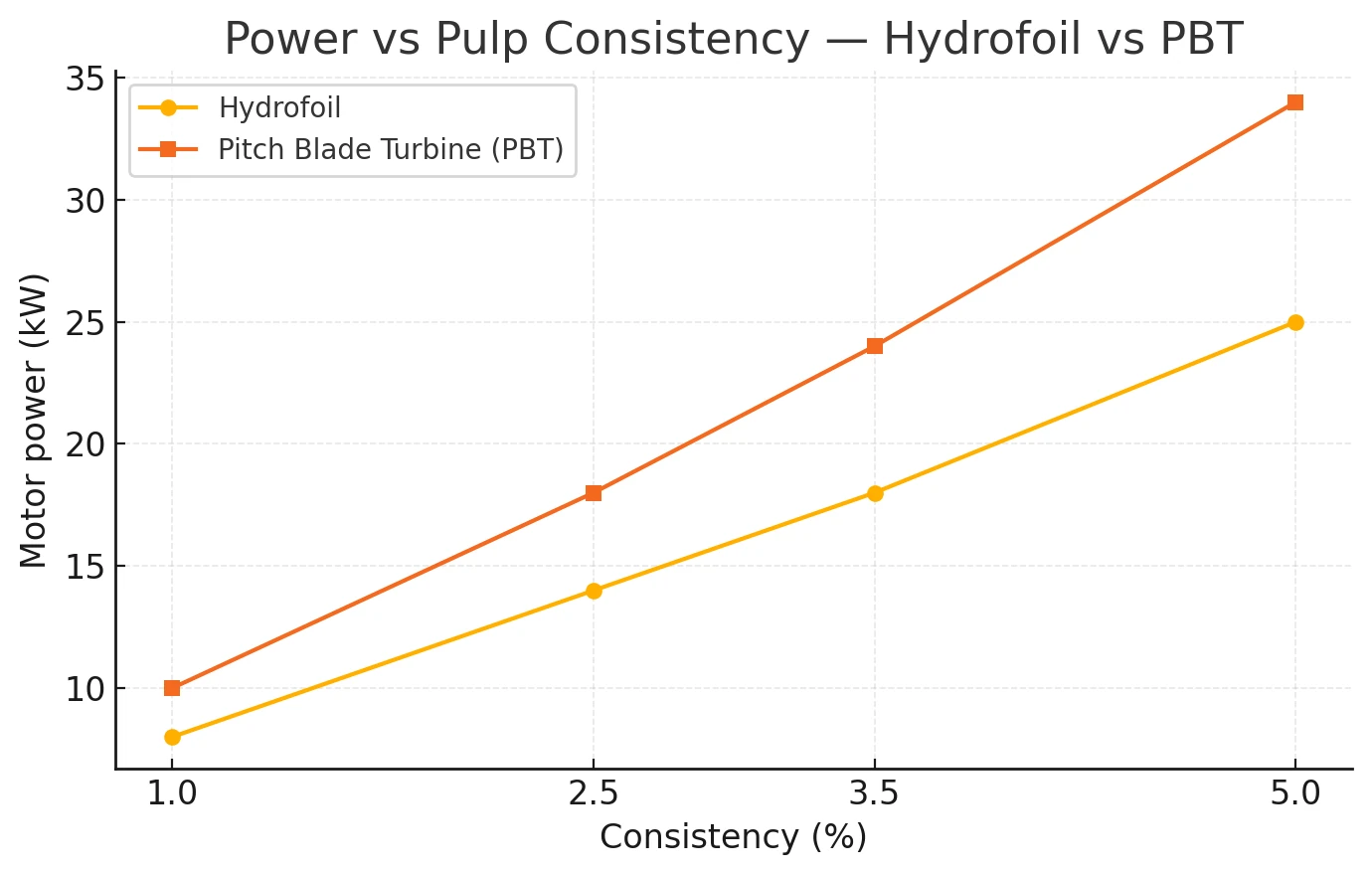

Power vs Pulp Consistency for Pulp Chest Agitator (Hydrofoil vs PBT)

Higher % consistency typically demands more motor power for the same turnover in a pulp chest agitator. This chart compares hydrofoil vs pitch blade turbine as consistency rises—useful when energy discipline matters in an agitator for paper mill. Assumptions: normalized at D/T≈0.40 with the same turnover target and SG≈1.0–1.05.

Chart Explanation

Hydrofoil shows a lower kW curve across the consistency band, reflecting better pumping-per-kW. At the high end (5.0%), the gap widens—hydrofoil needs ~25 kW versus ~34 kW for a similar duty with PBT, indicating a ~35% penalty if you prioritise lift over energy. At mid-range, both options remain viable; choose based on whether you value re-suspending settled mats (lean PBT) or day-to-day energy efficiency (lean hydrofoil). The engineering takeaway: lock the turnover target first, then pick the impeller family that meets it with the least operational burden.

If energy efficiency is your priority, explore our Hydrofoil Impeller overview; for lift-forward trade-offs, see the Pitch Blade Turbine page. SV Industries can translate your chest layout and consistency window into a buyer-ready proposal.

Key Design Features

A reliable pulp chest agitator combines a low-speed, large-diameter impeller, robust shaft and sealing options, energy-efficient drives (VFD + motor sized in kW), and corrosion-resistant materials (SS304/316L) to deliver tank-wide circulation with minimal shear.

SV Industries designs each pulp chest mixer design around these critical features so process engineers get predictable suspension, low power per m³, and serviceable assemblies.

Core features (what to specify)

- Impeller geometry & diameter: Hydrofoil or pitched-blade; Dimpeller ≈ 0.3–0.6 × tank Ø depending on level swing and L/D.

- Speed & power: Low RPM 25–120 RPM; motor sizing typically 1–55 kW for chest volumes from 5,000 L to hundreds of KL.

- Shaft & bearings: Solid shaft (Ø 40–80 mm typical depending on kW) with heavy-duty pillow/block or lantern bearings for long life.

- Sealing: Mechanical seals, cartridge seals, or magnetic drives for leak-sensitive pulp/filler systems.

- Mounting & access: Top-entry flanged mounting with removable coupling for quick maintenance.

- Materials & finish: SS304/316L wetted parts; carbon steel external with epoxy or rubber lining where applicable.

- Controls & instrumentation: VFD for soft start & turnover control; level/torque monitoring for anti-block protection.

| Parameter | Typical Range / Option | Purpose |

|---|---|---|

| Impeller D | 0.3–0.6 × tank Ø | Maintain floor sweep & circulation |

| RPM | 25–120 RPM | Low shear, high flow |

| Motor kW | 1–55 kW | Matches turnover & consistency |

| Wetted material | SS304 / SS316L | Corrosion & abrasion resistance |

See our Pitch Blade Turbine overview for impeller tradeoffs and explore the full product hub for compatible agitator assemblies.

Applications in Paper Mill Process

Pulp chest agitators from SV Industries are used across the paper mill for keeping pulp, broke and filler slurries uniformly suspended—typical applications include feed chests, blend chests, broke/whitewater chests, and dilution tanks. Each application drives different turnover, impeller and kW choices based on volume (L / KL), consistency (%) and viscosity (cP).

Common mill applications and recommended approaches:

- Pulp feed & blend chests: Maintain 2–5% consistency, turnover 10–30 min. Hydrofoil impellers for energy-efficient circulation; PBT if frequent re-suspension needed.

- Broke chest / reclaim tanks: Handle higher fiber load and occasional mats; pitched-blade turbines (PBT) or larger diameter hydrofoils with higher RPM (40–120 RPM).

- Whitewater & filler slurry tanks: Low solids, require gentle mixing to avoid entraining air — low RPM hydrofoil, motor 5–15 kW for small tanks (5,000 L) up to 20–55 kW for large surge chests (tens of m³ / KL).

- Dilution & chemical dosing tanks: Short turnover, accurate circulation; smaller impellers, precise VFD control for dosing consistency.

| Application | Consistency (%) | Turnover (min) | Impeller | RPM / kW |

|---|---|---|---|---|

| Pulp feed / blend | 2–5 | 10–30 | Hydrofoil / PBT | 25–80 RPM · 5–40 kW |

| Broke / reclaim | 3–8 | 10–25 | PBT / large D hydrofoil | 40–120 RPM · 15–55 kW |

| Whitewater / filler | <1–2 | 5–20 | Hydrofoil (low shear) | 25–60 RPM · 5–20 kW |

| Dilution / dosing | variable | 2–15 | Small hydrofoil / paddle | 30–120 RPM · 1–15 kW |

For tailored selection and reliability, see our Agitator solutions or the Pitch Blade Turbine overview for high-lift needs. SV Industries acts as a trusted pulp chest agitator manufacturer—matching design to your process conditions.

Pulp Chest Agitator for Large Volume

For very large chests, a side-entry pulp chest agitator is often the most practical way to maintain uniform suspension without major structural changes. SV Industries designs side-entry solutions that cover wide footprints, minimise dead zones, and stay service-friendly for high-uptime mills.

Large-volume storage brings real challenges: long flow paths, level swings, and access limits around platforms. A single top entry may struggle to push circulation wall-to-wall; side-entry mounting lets us direct flow where the chest actually needs it and simplify seal access. As a pulp chest agitator manufacturer, SV Industries focuses on circulation-first flow paths and nozzle positioning, so your operators aren’t “chasing” settling or foam during transfers.

Selection note: In very wide chests, staggered side-entry placements reduce shadow zones. Share a simple plan view with inlets/outlets; we’ll map a flow route that prioritises suspension and easy maintenance.

Explore related assemblies in our Product hub and browse installed references in the Gallery. This section pairs well with your side-entry agitator image for visual context.

| Factor | Side-entry agitator | Top entry (for comparison) |

|---|---|---|

| Coverage in wide tanks | Directed sweep along long walls | May leave distant corners under-served |

| Retrofit complexity | Uses existing side nozzles or new pads | Often needs bigger roof access |

| Service & seal access | Ground-level or mezzanine access | Work-at-height for many tasks |

| Foam/air control | Flow can avoid surface drawdown | Needs careful surface management |

Paper Pulp Chest Agitator for Small Volume

For compact chests, a top entry pulp chest agitator gives reliable suspension with simple access and clean surface management. SV Industries prioritises circulation-first flow paths so small tanks stay uniform through starts, stops, and level changes—without overengineering.

Small-volume storage has its own realities: tight platforms, short hold times, frequent batching, and quick grade changes. A top entry layout keeps the drive accessible, minimises footprint, and allows a smooth surface return that helps avoid foam and air pick-up. As a pulp chest agitator manufacturer, SV Industries maps your inlet/outlet positions and level swing, then proposes an impeller family and mounting that favour stable, low-maintenance operation.

Selection note: Share a simple sketch (plan + level range). We’ll align the flow path to your inlet jet and corners so fibers stay moving even at the lowest operating levels.

For energy-aware impeller options suitable to top entry layouts, see our Hydrofoil Impeller guide in the Agitator section. When you add your top entry agitator image, use a caption like: “Top entry pulp chest agitator—clean surface return and easy access (SV Industries).”

| Buyer concern | Top entry approach | Outcome |

|---|---|---|

| Limited platform space | Compact drive and single top nozzle use | Easy fit without layout overhaul |

| Frequent start/stop | Recipe-based ramp profiles | Smoother restarts, less operator “nudging” |

| Foam during transfer | Gentle surface return path | Lower air entrainment risk |

| Quick cleanouts | Service-friendly access from top | Faster planned maintenance |

How to Select the Right Pulp Chest Agitator (Buyer Guide)

Select a pulp chest agitator by matching tank volume (L / KL), pulp consistency (%), viscosity (cP) and required turnover time to an impeller type, diameter and motor kW. Start with measured tank geometry + process targets and iterate with Dimpeller (0.3–0.6×tank Ø), RPM (25–120) and kW (5–55) to get floor sweep without excess shear.

SV Industries recommends a structured buyer checklist—collect the items below first, then follow the sizing steps.

Quick buyer checklist (what you must know)

- Tank volume (L and KL) and shape (flat/sloped bottom; L/D).

- Pulp consistency (%) and operating viscosity (cP) at process temperature.

- Maximum level swing (%) and inlet/outlet locations.

- Acceptable turnover time (min) and anti-foam/air sensitivity.

- Materials (SS304 / SS316L) and sealing preference (mechanical / magnetic).

Stepwise selection

- Estimate flow (Q) from turnover target (Volume ÷ turnover time).

- Choose impeller family: hydrofoil for energy-efficient pumping; PBT for stronger lift.

- Select Dimpeller as 0.3–0.6×tank Ø — larger for deep tanks or big level swings.

- Calculate RPM & kW using manufacturer’s charts or request a model; include VFD for control.

- Specify installation: top-entry flange, seal type, access for maintenance.

| Buyer Input | Recommended Spec | Why it matters |

|---|---|---|

| Volume (L / KL) | Choose motor kW & Dimpeller | Determines flow & turnover |

| Consistency (%) | Impeller type, kW multiplier | Higher % → more power |

| Level swing (%) | Use larger Dimpeller or staged design | Prevents dead zones |

Use our Vessel Volume Calculator to confirm volume and review typical assemblies in our Agitator catalog. SV Industries, as an experienced pulp chest agitator manufacturer, can convert your inputs into a quick proposal.

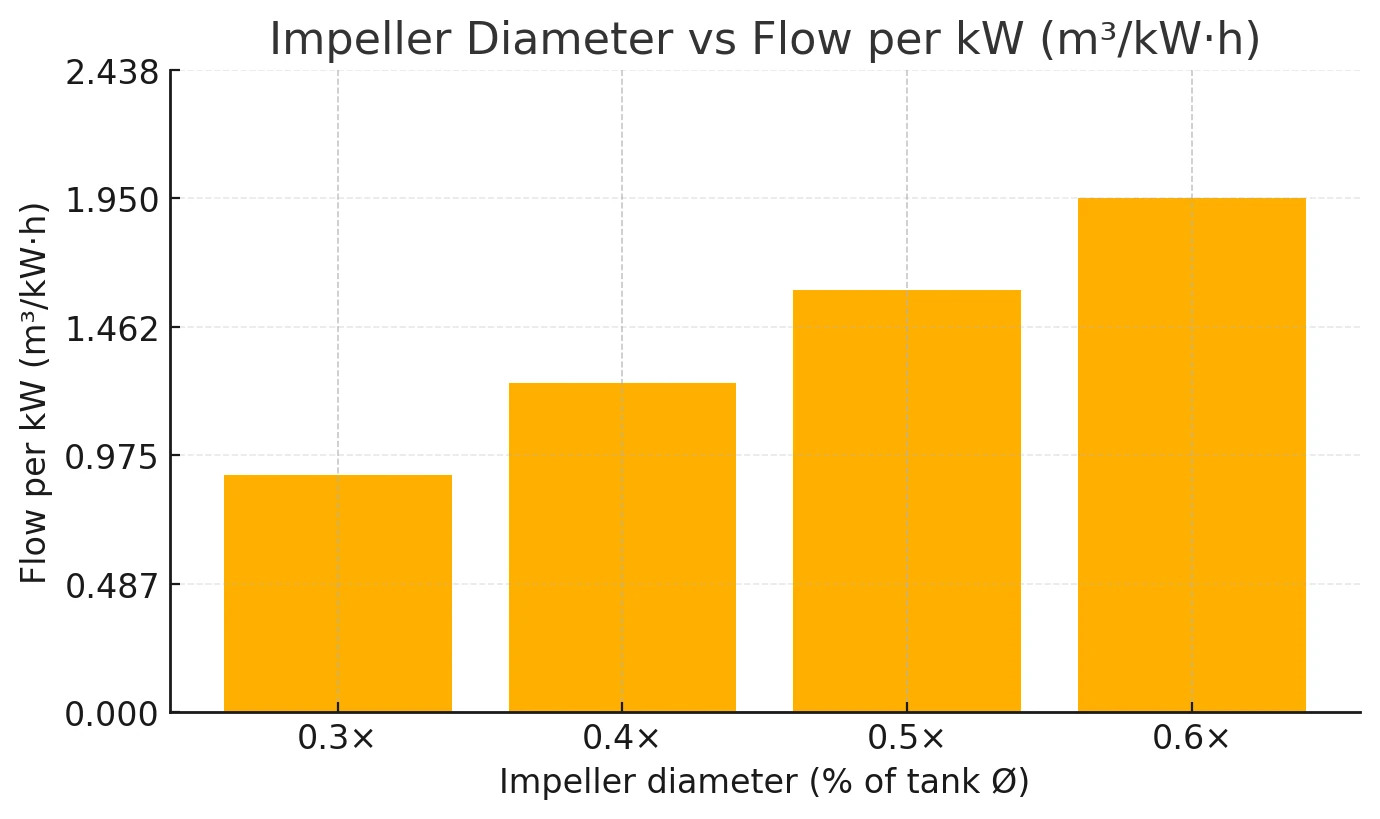

Impeller D (% of tank Ø) vs Flow per kW — Efficiency for Pulp Chest Agitator

When chest geometry or level swing changes, impeller diameter strongly affects pumping efficiency (flow per kW), which drives operational cost and turnover. This bar chart compares estimated flow per kW for impeller diameters of 0.3×–0.6× tank Ø under a constant turnover target. Assumption: normalized at the same RPM and turnover, water-like SG = 1.0.

Chart Explanation

Explanation: As the impeller diameter increases from 0.3× to 0.6× tank Ø, flow per kW rises noticeably (from ~0.90 to ~1.95 m³/kW·h in these estimates), showing a clear efficiency gain. Larger impellers reduce the motor energy needed for the same turnover, but may conflict with access or platform constraints—trade-offs SV Industries helps you evaluate. Engineering takeaway: if retrofit space allows, prioritise larger diameters for energy-sensitive applications; otherwise balance diameter with serviceability and floor-sweep needs.

See our Hydrofoil Impeller guidance for energy-focused impeller choices and contact SV Industries for a tailored, buyer-ready plan.

Technical Specifications

Technical specifications for a pulp chest agitator are best presented as configurable bands (impeller family, drive & control, sealing, materials) rather than fixed numbers. SV Industries converts your process inputs into a tailored specification sheet after a short site review.

This section outlines specification categories and common options—without giving final sizing—so buyers can understand choices and what information to prepare for a proposal.

| Parameter | Typical Range / Option | Notes / Units |

|---|---|---|

| Impeller diameter (D) | 0.3–0.6 × tank Ø | Dimensionless (fraction) |

| Speed | 25–120 RPM | Low-shear operation |

| Motor power | 1–55 kW | Depends on volume & consistency |

| Shaft | Ø 40–100 mm (solid) | Material: SS316 / SS304 / EN8 |

| Sealing | Mechanical cartridge / Magnetic drive | Zero-leak option available |

| Bearings | Pillow-block or lantern | Sized to kW and axial loads |

| Wetted parts | SS304 / SS316L / lined carbon steel | For abrasion/corrosion resistance |

| Controls | VFD, torque monitor, soft start | Recommended for turnover control |

| Operating temp | Ambient to 120 °C | Higher temp options on request |

| Design standards | ASME / EN / IS options | Documentation & QA on supply |

see our Hydrofoil Impeller guide and browse typical assemblies in the main Agitator catalogue. SV Industries can produce datasheets, GA drawings and torque curves on request.

Why Choose SV Industries (Manufacturer Credibility)

Choose SV Industries because we combine field-tested pulp chest agitator designs, in-house fabrication, and buyer-focused support to solve suspension and handling issues without over-prescribing technical details. We guide buyers from problem definition to a practical proposal.

Trust is built from repeatable delivery and clear processes. SV Industries focuses on three credibility pillars: design-for-process (we prioritise your process goals, not generic specs), manufacturing quality (shop-tested assemblies and traceable materials), and after-sales support (installation guidance, commissioning assistance and spare parts availability). This approach reassures plant heads and procurement teams that risk is minimized and ROI conversations stay practical.

Key credibility signals (what procurement looks for):

- Proven assemblies built to industry standards and documented factory testing.

- Flexible sealing and access options to suit leak-risk or maintenance preferences.

- Clear handover: GA drawings, inspection checklists, and commissioning support.

- Localised service and spare-part readiness to reduce downtime risk.

| Buyer concern | How SV Industries addresses it |

|---|---|

| Design confidence | Process-led proposals and documented options |

| Manufacturing quality | Shop assembly & test records |

| Maintainability | Access-friendly mounting and spares plan |

| After-sales | Site support and parts availability |

Request a documented case study or factory acceptance snapshot from SV Industries for the nearest comparable application — it’s the fastest way to validate fit.

Frequently Asked Questions (FAQs)

Pulp settling in the chest—what’s the first fix to try?

Check the flow pattern: floor sweep, surface return, and dead zones near corners. If operators are “chasing” levels, you likely need an impeller family and control recipe tuned to your level swing rather than more speed.

Foam during transfer—agitator or process issue?

Usually both. Aggressive surface draw and poor return paths amplify foam. We bias toward circulation-first setups and gentle surface management so air isn’t pulled in.

Top entry vs side entry—what works better for pulp chests?

Top entry is preferred for suspension control, access, and sealing choices. Side entry can be retrofit-friendly in tight spaces but needs careful placement to avoid blind spots.

Frequent start/stop causes re-suspension delays—how to stabilize?

Use staged ramp profiles and known “recipe” set-points for restart, rather than manual nudging. This gets fibers mobile without shocking the system.

Seal drip or leakage—what should I change first?

Confirm alignment, run out and access for routine checks. If the medium is sensitive, move to sealing solutions that are maintenance-friendly and aligned to your leak-risk tolerance.

Power feels high—how to reduce without losing suspension?

Cut over-mixing, not circulation. Focus on turnover control, level-aware set-points, and an impeller family that gives more pumping for the same effort.

Can we retrofit without cutting new nozzles?

Often yes. We align mounting and access to existing platforms and clearances, then tune the flow path to your chest geometry.

What inputs do you need to size an agitator for pulp chests?

Chest layout, level variation, pulp description, and any risk notes (foam, leak, hygiene). That’s enough for a credible, buyer-ready proposal.

Which impeller suits a pulp suspension mixer?

Where energy discipline matters, use a circulation-first profile; when re-suspending settled mats is the priority, use a lift-oriented profile. We propose both options with trade-offs.

How do I avoid air entrainment in blend chests?

Prevent vortex formation, manage return paths near the surface, and avoid aggressive drawdown exactly when levels are lowest.

Next Steps: Partner with SV Industries for Your Pulp Chest Agitator

A well-chosen pulp chest agitator keeps fibers uniformly suspended, reduces foaming and restarts cleanly—without overengineering. SV Industries turns real plant constraints into a practical, documentation-ready proposal.

When uptime matters, guesswork hurts. Instead of chasing specs, align on symptoms, chest layout, and operating patterns. SV Industries will translate that into an impeller family, mounting approach, sealing choice, and commissioning plan that fit your agitator for paper mill needs—clear, defensible, and easy to action.

| Your input | Our response |

|---|---|

| Chest layout, level variation, access limits | Installation concept and maintenance-friendly mounting |

| Pulp description and operating patterns | Impeller family recommendation focused on circulation and stability |

| Risk notes (leak, foam, hygiene) | Sealing approach and start/stop recipe for smooth operation |

| Procurement timeline | Handover plan: drawings, checks, and commissioning steps |

Share your chest layout and current pain points—SV Industries will prepare a concise, buyer-focused plan you can use internally. Contact SV Industries · See the Agitator overview.