Agitator Manufacturer - SV Industries

At SV Industries, we specialize in the design and manufacturing of high-performance industrial agitators for a wide range of sectors including chemical, pharmaceutical, food processing, cosmetics, and water treatment industries. With decades of experience and precision engineering capabilities, we deliver custom-built agitators that offer maximum mixing efficiency, durability, and low maintenance performance.

Whether you require an agitator for high-viscosity liquids, a turbine agitator for shear-sensitive applications, or a GMP-compliant mixing solution for pharmaceutical environments, SV Industries provides tailored solutions built in SS304, SS316, and other premium materials. Our facility is based in India, and we proudly serve both domestic and global clients with consistent quality and timely delivery.

We don’t just build agitators — we engineer solutions that enhance your process efficiency and support your production goals. Browse our extensive product range, including our Paddle Impeller and Anchor Agitator, or check out our full line of industrial agitators to find the perfect fit for your application.

What is an Agitator?

An agitator is a mechanical device designed to mix, stir, or circulate fluids and solids inside tanks and vessels. It plays a critical role in ensuring uniform consistency, heat transfer, and chemical reaction efficiency during various industrial processes. Agitators are used in various industries to ensure uniform mixing, blending, and chemical reactions, and they are essential in chemical, pharmaceutical, food and beverage, and other manufacturing processes.

🔍 What is an agitator used for?

An agitator is used to blend liquids, dissolve powders, suspend particles, and maintain homogeneity in processes like chemical mixing, pharmaceutical formulation, and food processing.

How Does an Agitator Work? – Working Principle Explained

An agitator works by converting mechanical energy into fluid motion, ensuring thorough mixing and uniform distribution of materials within a tank or vessel. The process involves a rotating shaft connected to an impeller, which creates flow patterns in the fluid.

⚙️ Step-by-Step Working of an Industrial Agitator:

Motor Activation

The motor powers the agitator shaft, initiating rotational motion.Impeller Rotation

The impeller (e.g., anchor, paddle, turbine) mounted on the shaft begins to rotate inside the tank.Fluid Motion Generation

The impeller creates axial, radial, or tangential flow patterns, depending on its design.Mixing Action

The fluid experiences turbulence and vortex motion, leading to blending, solid suspension, or heat exchange.Homogenization

Solids, liquids, or gases are uniformly distributed across the vessel for a consistent end product.

🔍 How does an agitator mix liquids or powders?

An agitator uses a rotating impeller to move the fluid or powder in a tank, creating circulating flow that blends all ingredients evenly.

🔗 Explore Mixing Technologies from SV Industries:

Types of Agitators Manufactured by SV Industries

At SV Industries, we design and manufacture a wide range of industrial agitators to suit diverse mixing requirements across various industries. Each agitator type is optimized for specific viscosity, mixing speed, and flow characteristics, ensuring precise and efficient performance.

A low-shear, gentle mixer ideal for viscous materials like slurries, creams, or resins.

Designed for high-viscosity fluids, this impeller scrapes the vessel wall to prevent buildup and improve heat transfer.

A high-shear radial flow impeller, perfect for gas dispersion and aeration in fermenters and bioreactors.

Known for energy efficiency and smooth axial flow, used for gentle but thorough mixing of low-viscosity fluids.

A versatile impeller capable of handling both axial and radial flow, used in wide-ranging mixing applications.

Reduces power consumption while enhancing gas-liquid contact — great for gas-liquid mass transfer.

Best suited for ultra-high-viscosity applications like adhesives, polymers, or cosmetic pastes.

| Agitator Type | Flow Type | Shear Level | Viscosity Range | Best for Applications Like |

|---|---|---|---|---|

| Paddle Impeller | Radial / Gentle | Low | Medium to High | Slurries, Paints, Resins |

| Anchor Impeller | Radial (Wall-Scrape) | Low-Medium | High | Creams, Pastes, Viscous Syrups |

| Rushton Turbine | Radial | High | Low to Medium | Fermentation, Aeration, Bioreactors |

| Hydrofoil Impeller | Axial | Low | Low | Water-like Fluids, Pharma Mixing |

| Pitch Blade Turbine | Axial + Radial | Medium | Medium | Versatile Use – Chemicals, Wastewater |

| Concave Disc Impeller | Radial + Gas Flow | Medium-High | Low to Medium | Gas-Liquid Mixing, Mass Transfer |

| Helical Ribbon Impeller | Helical Axial | Low | Very High | Polymers, Adhesives, Personal Care |

We also offer tailor-made impellers and shaft configurations based on your tank size, fluid dynamics, and process goals. Contact Us to request a custom solution.

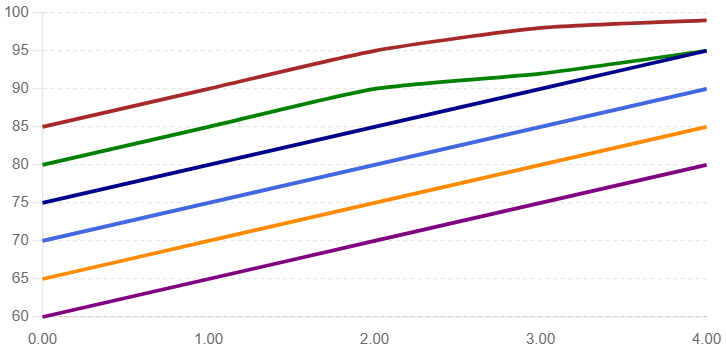

Impeller Comparison & Performance Charts

Selecting the right impeller is crucial for optimizing mixing performance, energy efficiency, and product quality. Below are detailed comparison charts to help you analyze and choose the best impeller type based on your specific industrial requirements.

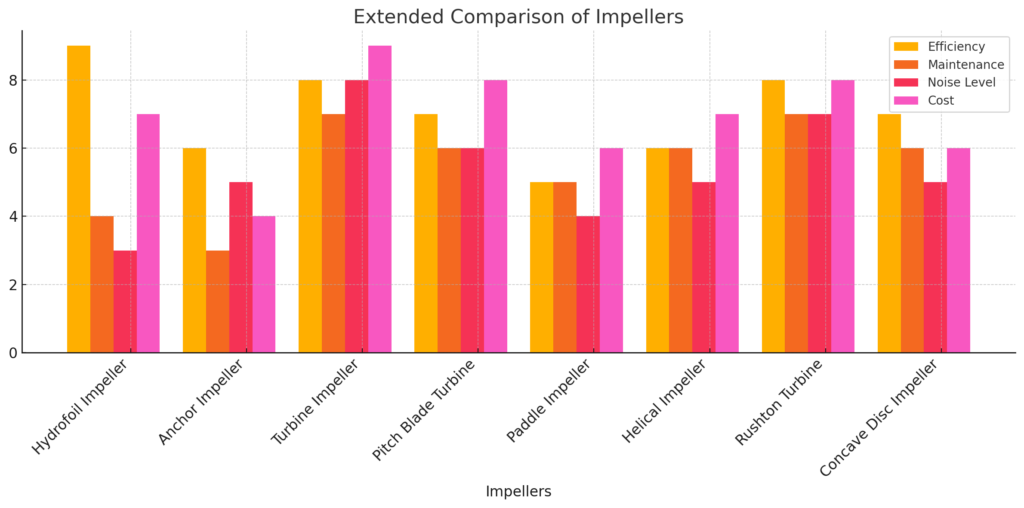

📊 Chart 1: Efficiency, Cost, Maintenance & Noise Level

Choosing the right type of impeller significantly impacts your process efficiency, energy consumption, and maintenance cost. At SV Industries, we manufacture a wide range of industrial agitators including Paddle Impeller, Rushton Turbine, Anchor Impeller, and Hydrofoil Impeller, each suited for specific viscosity levels, mixing speeds, and industrial applications.

To simplify the selection process, we’ve prepared a comparative table based on four critical parameters: efficiency, cost, maintenance, and noise level.

From the chart above, it’s clear that:

Hydrofoil impellers are ideal for low-noise, high-efficiency operations, especially in continuous mixing processes.

Paddle impellers offer cost-effective performance for low-shear mixing in applications like Industrial Chemical Reactor.

Rushton turbines, though slightly higher in noise and maintenance, are excellent for gas dispersion in chemical reactors.

Anchor impellers are preferred for high-viscosity materials where low RPM is required, commonly used in jacketed vessels and limpet coil reactors.

Understanding this comparison can help you optimize your process and reduce long-term operational costs. For more guidance, check out our blog on how to select the right agitator.

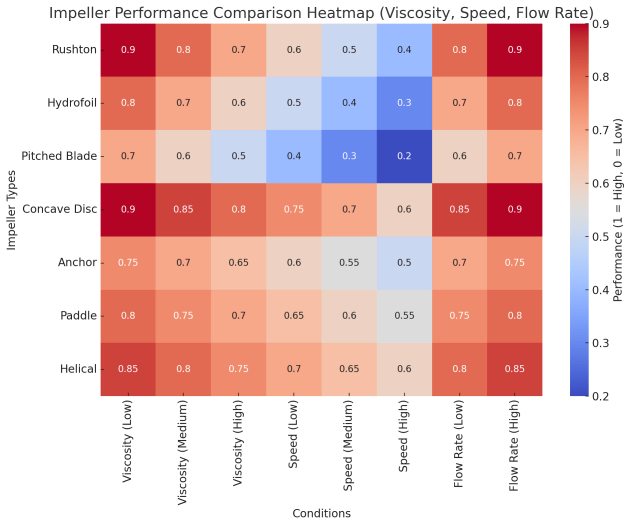

📊 Chart 2: Performance Heatmap (Viscosity, Speed, Flow Rate)

Which impeller performs best for your process viscosity and mixing speed? Whether you’re handling thin fluids or high-viscosity slurries, this performance heatmap helps visualize the ideal impeller choice based on your required flow rate, RPM, and fluid properties.

At SV Industries, we offer a complete range of impellers—from Hydrofoil for energy-efficient flow, to Anchor Impeller for slow-speed, high-viscosity mixing—customized for chemical, pharma, food, and cosmetics industries.

Our heatmap visualization below will guide your selection by mapping the performance of impeller types across various industrial conditions.

From the heatmap:

Hydrofoil impellers are best suited for low-viscosity fluids and high-speed mixing, ensuring axial flow with minimal turbulence.

Anchor and Paddle impellers dominate in high-viscosity applications with slow speeds, where gentle shear is crucial.

Rushton turbines perform optimally in medium-viscosity fluids that require radial flow and gas-liquid dispersion.

👉 For deeper analysis and custom solutions, explore our expert blog or contact us for a tailored recommendation based on your fluid characteristics and mixing goals.

📞 Ready to optimize your process? Get a quote today or check out our complete agitator solutions:

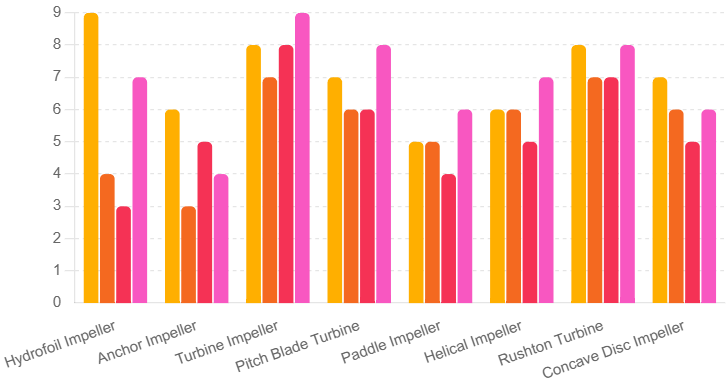

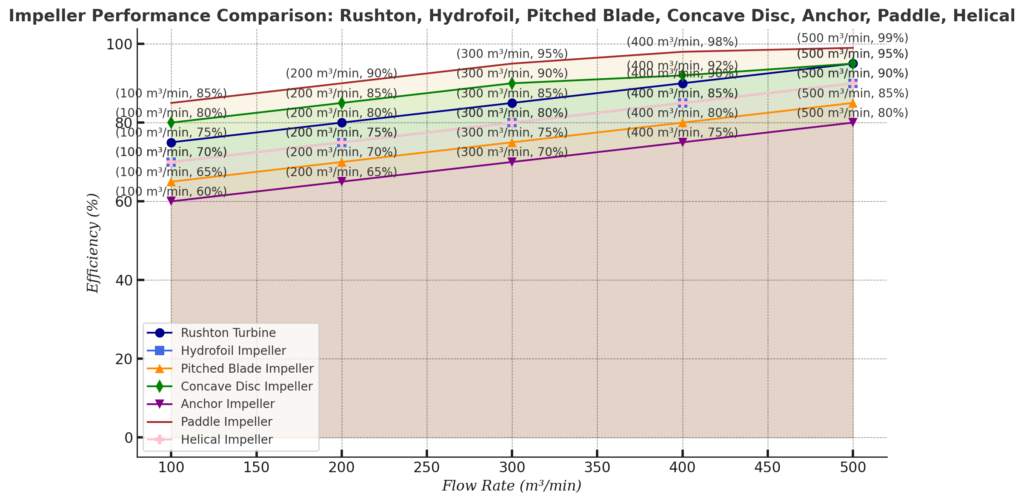

📊 Chart 3: Performance Comparison of 7 Industrial Impellers

How do different industrial impellers perform across critical parameters like flow pattern, power consumption, mixing efficiency, and scalability?

This comprehensive impeller performance comparison chart simplifies your selection by benchmarking 7 key impeller types used across industries like pharmaceuticals, chemicals, cosmetics, and food processing.

Explore the strengths and limitations of each impeller—Anchor, Paddle, Rushton, Hydrofoil, Pitched Blade, Helical, and Concave Disc—to help you make informed decisions when selecting the ideal agitator for your application.

Based on the chart above:

Hydrofoil impellers offer high-efficiency axial flow, ideal for low-viscosity and high-throughput applications.

Rushton turbines are unmatched for gas dispersion and shear-heavy mixing.

Helical and Anchor impellers perform well in viscous systems, especially in reactor vessels and jacketed tanks.

Paddle impellers offer low-cost, low-shear mixing, useful in Chemical Process Reactor.

Concave Disc impellers balance radial and axial flow, ideal for general-purpose blending.

Pitched blade turbines perform well across a wide viscosity range and offer moderate shear with scalable performance.

Need help choosing the best impeller? Talk to our experts or read our detailed blog:

📘 How to Select the Right Agitator

📞 Get a Quote Now for custom design recommendations.

Design Features of SV Industries' Industrial Agitators

At SV Industries, our industrial agitators are engineered with cutting-edge design features that ensure durability, hygiene, and performance across a wide range of chemical, pharmaceutical, cosmetic, and food processing applications. Whether your operation demands GMP-certified equipment or custom shaft-seal configurations, we deliver fully optimized agitator systems designed to match your process.

🧩 CAD-Based Precision Engineering

Every agitator is modeled using advanced CAD software to offer:

Precise dimensional control for seamless integration with tanks & vessels

Custom impeller placement for maximum turbulence control and flow optimization

Accurate simulations for CFD analysis, RPM selection, and power draw prediction

💡 Need help integrating agitators into a jacketed or limpet coil vessel? Explore our specialized solutions:

→ Limpet Coil Reactor Vessel

→ SS Jacketed Vessel

🛡️ GMP Compliance for Regulated Industries

For customers in pharmaceutical, biotech, and cosmetics, we offer:

GMP-compliant agitator surfaces with sanitary polish (up to Ra < 0.6 µm)

CIP/SIP-compatible shafts for clean-in-place & steam-in-place operations

Hygienic design with no dead zones, flush seals, and FDA-grade gaskets

All hygienic agitators are designed to meet FDA, ASME BPE, and EHEDG standards as applicable.

🧲 Stainless Steel Grades and Surface Finishes

Our agitators are available in:

SS316 / SS316L: Excellent for acidic, saline, or pharmaceutical applications

SS304: Cost-effective choice for general industrial use

Custom surface treatments like electropolishing, passivation, and mirror finish for enhanced corrosion resistance and hygiene

⚙️ Shaft Configurations & Mechanical Seal Options

We offer robust agitator shafts in hollow or solid configurations, depending on the mixing torque and tank geometry. You can choose from:

Top entry / bottom entry / side entry shafts

Single or double mechanical seals, stuffing box, or dry-running seals

Bearing housings and flange couplings for heavy-duty agitation

Want custom seal integration for a reactor or tank?

🔗 Visit: Reactor Vessel Manufacturer

🚀 Designed for Performance & Customization

Each agitator is tested for:

Dynamic balancing of shafts

Vibration-free operation even at high RPM

Compatibility with variable frequency drives (VFDs)

Pressure / vacuum service readiness

📞 Want a tailored agitator design for your plant? Contact Us or request a consultation from SV Industries today!

Technical Specifications of SV Industries' Agitators

When selecting an industrial agitator, it’s essential to understand the key specifications that ensure optimal mixing performance. At SV Industries, we manufacture agitators designed for a wide range of industrial applications—from low-viscosity liquids to high-viscosity slurries.

Below is a detailed specification table that outlines standard configurations. Customization is available based on your industry needs. For help choosing the right agitator, explore our Agitator Selection Guide.

| Motor Power (HP) | RPM | Impeller Type | Mounting Type | Volume Capacity (Liters) | MOC | Seal Type | Shaft Diameter & Length | Impeller Diameter | Application Suitability |

|---|---|---|---|---|---|---|---|---|---|

| 0.5 – 100 HP | 20 – 1440 RPM | Anchor, Paddle, Rushton, Hydrofoil, Pitched Blade, Concave Disc, Helical | Top / Side / Bottom | 100 – 100,000 L | SS304 / SS316 / Hastelloy / PTFE Coated | Mechanical / Gland / Lip Seal | Based on volume and torque requirements | Based on tank geometry and mixing intensity | Chemical Processing, Pharma, Paints & Coatings, Food & Beverages, Cosmetics, Water Treatment, Adhesives, Resins & Polymers, Petrochemicals, Dairy |

Every agitator manufactured by SV Industries is engineered with precision to deliver optimal mixing performance across a wide range of industries. Whether your process requires gentle blending or high-torque agitation, our agitators are designed and customized based on tank geometry, fluid viscosity, and batch volume.

With a motor power range from 0.5 HP to 100 HP, our agitators are suitable for everything from pilot-scale R&D setups to full-scale chemical processing plants. You can choose from seven advanced impeller types—Paddle, Anchor, Rushton, Hydrofoil, Pitched Blade, Concave Disc, and Helical—each tailored for specific flow patterns and mixing intensities.

We also offer engineering support to help you select the right shaft length and impeller diameter based on tank dimensions, aspect ratio, and the nature of your process fluid. Our team ensures that your equipment fits perfectly into your existing or new setup.

Need help finalizing specifications? Our experts are here to assist. Reach out to us through our Contact Us page.

Also explore our other specialized products:

• Reactor Vessels: https://sv-industries.com/reactor-vessel/

• Heat Exchangers: https://sv-industries.com/heat-exchanger/

• Storage Tanks: https://sv-industries.com/storage-tank/

• Ribbon Blenders: https://sv-industries.com/ribbon-blender/

Comparison: Agitator vs Mixer – What’s the Difference?

When it comes to industrial mixing and blending applications, many people ask, “Is an agitator the same as a mixer?” — and the answer is no. Although both are used for combining materials, their design, purpose, and performance differ significantly. Let’s understand the key differences between an agitator and a mixer to help you choose the right equipment for your process.

🔍 Agitator vs Mixer: Quick Comparison Table

| Feature | Agitator | Mixer |

|---|---|---|

| Purpose | Maintains material uniformity, prevents sedimentation | Ensures homogeneous blending of ingredients |

| Motion | Gentle stirring or circulation | High-shear or aggressive mixing |

| Applications | Chemicals, pharma, paints, viscous fluids | Food, powders, emulsions, semi-solids |

| Design | Uses impellers like anchor, paddle, hydrofoil | Uses blades, beaters, or rotating paddles |

| Working Volume Range | Ideal for large-scale batch or continuous process | Small to medium-scale production |

| Viscosity Handling | Efficient for medium to high-viscosity fluids | Limited to low or moderate viscosity |

| Maintenance | Requires periodic shaft seal inspection | Blade cleaning and motor servicing |

| Pricing | Higher due to engineering, seals, customization | Economical for standard applications |

Is an agitator the same as a mixer?

No, an agitator is used for gentle mixing and maintaining suspension in large vessels, while a mixer is designed for thorough blending of ingredients, often with higher shear forces. The right choice depends on your process requirements and material type.

✅ When to Use an Agitator Over a Mixer

If you’re dealing with chemical reactions, viscous materials, or require continuous movement without full homogenization, an agitator is ideal. Explore our Agitator Product Page for more technical details, impeller types, and design options. For high-shear or dry material mixing, consider our Ribbon Blender.

At SV Industries, we specialize in custom agitator solutions that suit specific viscosity levels, mixing speeds, and material compatibilities — whether it’s a Limpet Coil Reactor or a Jacketed Vessel.

🤝 Need Help Deciding?

Not sure whether your process needs an agitator or mixer? Reach out via our Contact Page — our experts will guide you with a tailored solution.

Industrial Applications of Our Agitators

At SV Industries, our industrial agitators are designed for maximum performance, durability, and versatility across a wide range of sectors. Whether you’re dealing with high-viscosity chemicals or delicate cosmetic formulations, we offer customized agitator solutions tailored to your process needs.

🧪 Chemical Industry

Our agitators are extensively used in chemical reactors, blending tanks, and processing vessels. From acid mixing to polymer suspension, we provide corrosion-resistant, high-torque agitators that handle harsh chemicals and complex reactions. Learn more about our Chemical Process Reactors and Industrial Chemical Reactors.

💊 Pharmaceutical Industry

Precision and cleanliness are vital. Our GMP-compliant agitators ensure uniform mixing, homogenization, and crystal growth for products like syrups, suspensions, and ointments. For sterile operations, we offer seal-tight agitators and CIP/SIP-compatible designs.

🎨 Paints & Coatings

For the paint and pigment industry, our agitators enable even dispersion of solids, maintaining viscosity and preventing settling during batch storage. The use of impellers like the Rushton Turbine ensures effective high-shear mixing.

💧 Water & Wastewater Treatment

Our agitators are deployed in flocculation tanks, aeration basins, and sludge digesters, ensuring thorough mixing, oxygen distribution, and residue prevention. We also provide energy-efficient impeller options like the Hydrofoil Impeller for continuous operation.

💅 Cosmetics & Personal Care

In the beauty industry, consistency matters. Our agitators are ideal for mixing creams, lotions, gels, and emulsions, offering smooth texture, no air entrapment, and shear control for sensitive ingredients. Custom impeller choices ensure perfect results every time.

🍲 Food & Beverage

Our food-grade agitators (available in SS 304/316) are used in sauce, beverage, oil, and dairy mixing. We maintain hygiene standards with sanitary seals and easy-cleaning options, ensuring contamination-free operation. Check our Storage Tank Solutions for integrated systems.

🛢️ Oil & Gas Industry

Our agitators support drilling fluids, refinery blending, and oil emulsification processes. Designed for heavy-duty applications, we offer explosion-proof motors, seismic mounts, and high-torque impellers like the Anchor Impeller for rugged environments.

Want a custom solution for your industry? Explore our Agitator Product Page or Contact Us today. Our expert team is ready to engineer a solution just for your process.

Why Choose SV Industries for Your Agitator Needs?

At SV Industries, we’re not just manufacturers — we’re solution partners in your industrial mixing journey. Here’s why industries across India trust us for their agitator systems:

✅ Energy-Efficient Designs

🔋 Save power with our low-energy agitator systems engineered for maximum fluid movement with minimal input.

✅ Maintenance-Free Operation

🛠️ Designed with high-quality mechanical seals and durable shaft bearings, our agitators are almost zero-maintenance, reducing downtime.

✅ Customized to Your Process

✅ Corrosion & Pressure Resistant

🧪 Built with SS 304/316 materials, our agitators resist chemical attack, high pressure, and extreme temperatures — ideal for harsh processing environments.

✅ Compact & Space-Saving Units

📏 With modular designs, our agitators are perfect for skid-based setups or space-restricted installations.

✅ Wide Industry Compatibility

🏭 From chemical reactors to food-grade mixers, cosmetic blenders, and wastewater agitators, we’ve got it all covered. Explore our Product Range.

✅ Reliable After-Sales Support

📞 Our dedicated service team ensures quick response, spare availability, and installation guidance across India.

✅ Trusted Manufacturer in Gujarat

🌐 We are a leading Agitator Manufacturer in Ahmedabad and Gujarat, serving clients PAN India with trusted delivery timelines and consistent quality.

📩 Ready to get started? Get in Touch or visit our Agitator Product Page to explore designs and specifications.

Our Agitator Manufacturing Showcase

At SV Industries, we take pride in our in-house agitator manufacturing capabilities backed by precision engineering, advanced infrastructure, and a skilled workforce. From design to dispatch, every step is carefully monitored to ensure top-notch quality and reliability.

Below is a glimpse into our shop floor, showing various stages of agitator manufacturing including fabrication, polishing, inspection, and packaging. Our facility in Ahmedabad is equipped to handle custom agitator builds for chemical, pharma, food, cosmetics, and more.

Whether you’re looking for a high-speed lab stirrer or an industrial-grade anchor agitator for a 50,000-liter reactor, we have the capacity and expertise to deliver it with perfection.

Image Gallery

At SV Industries, each agitator is manufactured with a focus on precision, durability, and performance. These images reflect our dedication to engineering excellence and transparent manufacturing practices. From raw material handling to final packaging, we ensure stringent quality checks at every stage.

We understand that every process and industry has its unique mixing requirements. That’s why our facility is equipped to deliver custom-built agitators tailored to your tank geometry, viscosity needs, and flow characteristics.

Looking for something specific like a high-speed Rushton turbine, a low-shear anchor agitator, or a multi-stage impeller setup? We’ve got you covered.

✅ Serving across industries: • Chemical & Pharma

• Food & Beverage

• Cosmetics & Paint

• Water Treatment & Fertilizer

• Adhesives & Biofuels

👉 To learn more about our advanced agitator types, explore:

Need expert guidance? Talk to Our Team for custom sizing and quote.

Agitator Performance Analysis

At SV Industries, every agitator design is backed by advanced engineering analysis to ensure optimum performance, mixing efficiency, and process reliability. Here’s how we evaluate and perfect our agitators:

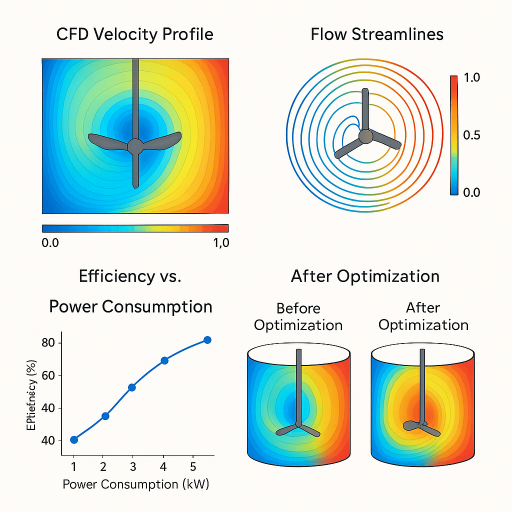

💻 Computational Fluid Dynamics (CFD)

We use CFD simulations to virtually model and analyze fluid movement inside the reactor or tank. This helps us:

Visualize velocity gradients, shear rates, and turbulence levels

Optimize impeller design for uniform mixing

Reduce dead zones and power consumption

With tools like ANSYS Fluent or SolidWorks Flow Simulation, our engineering team runs multiple iterations to fine-tune flow dynamics before manufacturing.

🔁 Flow Patterns & Mixing Zones

Based on the type of impeller — like Hydrofoil, Rushton, or Pitch Blade Turbine — we analyze various flow patterns such as:

Axial Flow: Ideal for top-to-bottom circulation, used in bulk blending

Radial Flow: High-shear mixing near impeller zone, perfect for emulsification

Tangential Flow: Promotes vortex generation, common in high-speed mixing

Each agitator is matched to your tank geometry to ensure maximum flow coverage and homogeneous product quality.

📈 Simulation-Based Optimization (Sample Visuals)

✅ Outcome of Our Analysis

Thanks to our in-depth performance evaluations, our agitators provide:

30–40% better mixing efficiency than standard designs

Lower power draw per m³ of fluid

Longer lifecycle with optimized stress distribution

Predictable process scaling from lab to production level

Want a CFD-optimized agitator for your process? Explore our custom-engineered options on the Agitator Page or Talk to our design team.

How to Select the Right Agitator for Your Process?

Choosing the right agitator is crucial for achieving uniform mixing, energy efficiency, and product quality. At SV Industries, we help you select the best agitator based on your process parameters.

🧪 Viscosity of the Material

Low Viscosity (e.g. water, alcohols): Use axial flow impellers

Medium to High Viscosity (e.g. creams, oils, slurries): Choose slow-speed, high-torque agitators

🧊 Tank Geometry

Cylindrical tanks need center-mounted impellers

Vertical tall tanks may need multiple impellers at various levels

🧴 Batch Volume

Small batches: Direct motor drive

Large batches: Gear-driven agitators for torque consistency

🔥 Purpose of Mixing

Homogenization & Blending → Hydrofoil / Pitch Blade

Heating with Limpet Coil or Jacket → Anchor type (for wall scraping)

Suspension of Solids → Rushton or Concave Disc

Shear-sensitive products → Use Paddle or Helical Ribbon

Still confused? Let our engineers guide you with a free consultation.

🔗 Visit our Agitator Product Page or Contact Us to get started.

Advantages of SV Industries' Agitators

🔧 Custom-Engineered Designs

Every agitator is tailored to your process needs, tank geometry, and viscosity range — ensuring maximum efficiency.

⚙️ High Mixing Efficiency

Our impellers are designed using CFD-based simulations, delivering optimized flow patterns for faster and uniform mixing.

⚡ Energy Saving Solutions

We use low-power, high-torque gear drives and efficient impeller profiles to reduce energy consumption without compromising performance.

🛠️ Low Maintenance & Long Life

Built with robust materials like SS316, Hastelloy, and PTFE coatings, our agitators are corrosion-resistant, durable, and need minimal upkeep.

🧪 Material Compatibility

Suitable for corrosive, high-viscosity, and sterile environments — ideal for chemical, pharma, food, and cosmetics industries.

🧩 Versatile Mounting Options

Choose from top-entry, bottom-entry, or side-mounted configurations to suit your tank design and process flow.

🔄 Sealing & Drive Variants Available

Wide range of mechanical seals, stuffing boxes, and drive types (gear/variable speed) available as per industry and safety requirements.

🛡️ Explosion Proof & Flameproof Options

Agitators for hazardous zones available with ATEX/Flameproof motors and certified enclosures.

🧠 Backed by Process Expertise

With years of experience in process equipment manufacturing, we go beyond just selling — we consult, recommend, and deliver complete solutions.

🛒 Looking for the perfect agitator for your process?

Request a Quote Now or call our technical team.

Frequently Asked Questions (FAQs) About Agitators

What is the best agitator for viscous fluids?

The best agitators for viscous or high-thickness fluids include Anchor Impellers, Paddle Mixers, and Helical Ribbon Agitators. These are designed to handle heavy materials like creams, gels, and syrups with ease.

👉 Learn more on our Anchor Impeller page

What are the types of impellers used in agitators?

Common impellers include Hydrofoil, Pitch Blade, Rushton Turbine, Anchor, Paddle, and Disc-type. Each type suits different flow patterns and viscosities.

👉 View all at SV Industries Impellers

Can agitators be used for corrosive chemicals?

Yes, we manufacture agitators using corrosion-resistant materials like SS 316L, Hastelloy, and PTFE coating. These agitators are ideal for acidic, alkaline, and chemically aggressive environments.

👉 Explore custom options on our Contact Page

What’s the difference between an agitator and a mixer?

An agitator is primarily used for maintaining uniformity and preventing sedimentation, while a mixer is used for homogenizing two or more substances.

How do I choose the right agitator for my process?

Choosing the right agitator depends on your fluid viscosity, tank size, mixing purpose, and tank shape.

👉 Use our detailed Agitator Selection Guide to make the right decision.

Do you offer agitators for the food, pharma, and cosmetic industries?

Absolutely. Our agitators meet GMP, sanitary, and hygienic design standards — perfect for food, pharmaceutical, and cosmetic applications.

Are your agitators energy efficient?

Yes, SV Industries designs agitators for optimized flow patterns, reduced power consumption, and minimal maintenance, saving both energy and operational cost.

Can I customize an agitator for my specific process?

Yes. At SV Industries, we offer fully customized agitator designs based on your tank size, process type, RPM, viscosity, and power requirement.

What materials are available for agitator construction?

We offer agitators in SS 304, SS 316, Hastelloy, Alloy 20, Titanium, and with PTFE linings for chemical resistance.

What is the maintenance requirement for a hydrofoil impeller agitator?

Hydrofoil impeller agitators require minimal maintenance, thanks to their robust design. Regular inspections, cleaning, and lubrication of moving parts ensure a long service life and consistent performance.

SV Industries: The Trusted Manufacturer and Supplier of Agitators

At SV Industries, we are more than just a manufacturer — we are your agitation technology partner. With years of expertise in process equipment engineering, we’ve earned the trust of clients across chemical, pharmaceutical, food, cosmetics, and water treatment industries.

From design to dispatch, every agitator is crafted with precision, keeping in mind your specific process needs, energy optimization, and longevity.

Why Industry Leaders Trust SV Industries:

✅ ISO-certified manufacturing standards

✅ In-house design, fabrication, and testing capabilities

✅ Wide range of impellers and agitator types under one roof

✅ Strong presence in Gujarat, Maharashtra, Rajasthan, and PAN India

✅ Excellent after-sales support and technical assistance

We proudly serve industries looking for long-term reliability, custom engineering, and value-driven solutions. Whether it’s a Hydrofoil Impeller, Anchor Agitator, or a complete Reactor System — SV Industries is the name professionals recommend.