Best Agitator Manufacturer in India

An agitator is a mechanical mixer that blends, circulates, and suspends solids inside tanks and reactors. SV Industries is a leading agitator manufacturer in India, delivering energy-efficient designs (hydrofoil, PBT, anchor, Rushton) engineered for chemicals, pharma, food, and water treatment—backed by ISO-grade quality, fast lead times, and nationwide support. Explore our Agitator range or contact us for sizing.

Why buyers choose SV Industries 💡

- Process-matched designs: From Hydrofoil for high flow at low power to Pitch Blade Turbine and Rushton for gas–liquid dispersion, plus anchor/paddle for high-viscosity duty.

- Lower lifecycle cost: Optimized D/T and RPM reduce kW draw without compromising mixing quality—ideal for continuous operations.

- Hygienic & robust builds: SS304/SS316L with correct surface finish for pharma/food; seal and drive options sized for uptime. See related vessels: SS Jacketed, Limpet-Coil Reactors.

- Engineering support: Quick selection guidance, GA drawings, and calculators like Vessel Volume & Level and Limpet-Coil Length to speed decisions.

Get started 📞

Tell us your tank size, viscosity/SG, duty (blending, suspension, heat transfer, flocculation), and preferred impeller style. We’ll recommend the right configuration and quote.

→ Contact SV Industries • About Us • Gallery

What is an Agitator?

An agitator is a mechanical mixing device that rotates one or more impellers inside a tank or reactor to circulate fluid, blend ingredients, suspend solids, and improve heat/mass transfer. By selecting the right impeller type, diameter (D/T), and RPM, an agitator delivers the required flow pattern with minimum power and high reliability.

Agitators are central to process industries—chemicals, pharma, food, paints/inks, and water treatment—where consistent quality and cycle-time matter. Explore the basics and common impeller families on our Agitator page, or see specific designs such as Hydrofoil, Pitch Blade Turbine, Rushton, and Anchor.

What does an agitator actually do?

- Blending & dissolution: Mix liquids, dissolve powders faster.

- Suspension: Keep solids uniformly distributed; avoid settling.

- Gas–liquid dispersion: For aeration, hydrogenation, fermentation (e.g., Rushton).

- Heat transfer support: Improve jacket/limpet efficiency by renewing boundary layers.

- Shear control: From gentle flocculation to high-shear dispersion depending on impeller.

Axial vs Radial flow — which is right for you?

| Flow Pattern | Best For | Typical Impellers | Key Advantages |

|---|---|---|---|

| Axial (top↔bottom circulation) | Bulk blending, solid suspension, heat transfer on water-like fluids | Hydrofoil, PBT (pitched) | High flow per kW, lower power draw, uniform circulation |

| Radial (outward jetting) | Gas–liquid dispersion, intense turbulence near impeller | Rushton, Flat Blade (radial) | Strong shear & gas dispersion; ideal for sparged systems |

| Wall-sweeping | High-viscosity fluids, heat transfer at wall | Anchor, Paddle, Helical | Scrapes/refreshes boundary layer; prevents dead zones |

How an Agitator Works ?

An agitator uses a motor/gearbox to rotate an impeller on a shaft inside a vessel, creating controlled flow patterns (axial, radial, or wall-sweeping). With the right impeller type, diameter ratio (D/T), RPM, baffles, and vessel geometry, the system delivers fast blending, reliable solid suspension, effective gas dispersion, and improved heat/mass transfer with minimum power. See our Agitator range or talk to us for selection.

Core elements & what they do ⚙️

- Motor + Gearbox: Sets torque/RPM to match duty; VFD ready for speed control.

- Shaft & Hub: Transmit power; sized for critical speed margin and low vibration.

- Impeller: Heart of hydraulics—blade geometry defines flow (axial/radial/sweeping) and shear. Explore: Hydrofoil, Pitch Blade Turbine, Rushton, Anchor, Paddle.

- Baffles (in tank): Prevent vortexing, convert swirl to top↔bottom circulation for faster mixing.

- Seal/Bearing Housing: Mechanical seal or stuffing box chosen for pressure, temperature, and media compatibility.

- Mounting/Base: Keeps alignment true; integrates with SS Jacketed or Limpet-Coil Reactors.

What exactly happens inside the tank? 🌊

- Axial flow: Liquid moves top→bottom→top, sweeping the whole volume for quick blending and suspension (typical of hydrofoils and pitched blades).

- Radial flow: High turbulence jets outward from the impeller—excellent for gas dispersion (classic Rushton duty).

- Wall-sweeping: Anchor/paddle/helical push fluid along the walls to refresh the boundary layer—vital in viscous or heat-transfer jobs.

- Correct D/T, RPM, and baffling shape these patterns so you get the result in less time and with fewer kW.

Typical operating bands by impeller 📊

| Impeller (Flow) | Best For | RPM Band* | Viscosity Range | Notes |

|---|---|---|---|---|

| Hydrofoil (Axial) | Bulk blending, solid suspension, heat transfer in water-like fluids | 80–300 | ~1–500 cP | High flow per kW; energy efficient |

| PBT (Axial) | General purpose mixing; moderate viscosity | 60–250 | ~1–2,000 cP | Versatile; tuneable for blend vs shear |

| Rushton (Radial) | Gas–liquid dispersion, aeration, hydrogenation | 100–600 | ~1–500 cP | High turbulence near blades; needs baffles |

| Anchor / Paddle (Wall-sweep) | High-viscosity, heat-sensitive products; wall heat transfer | 10–80 | ~2,000–100,000+ cP | Prevents dead zones; ideal with jackets/limpet coils |

*Actual RPM depends on tank size, baffles, duty, and motor/gearbox selection.

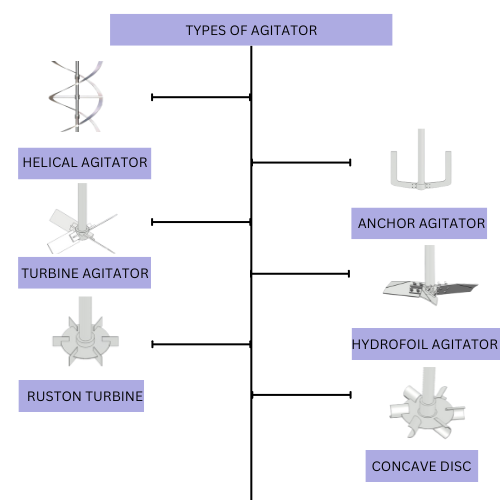

Agitator Types & Where Each Fits

Below is a quick, engineer-friendly guide to help you match impeller type → duty → viscosity/RPM band. Click into individual impellers for deeper specs and use-cases.

Hydrofoil (High Flow, Low Power) 💨

- Best for: Bulk blending, solid suspension, heat transfer on water-like to mildly viscous fluids.

- Typical RPM band: 80–300 (size & duty dependent)

- Viscosity range: ~1–500 cP

- Why choose it: Highest flow per kW, excellent circulation, shorter blend times.

- Watchouts: Not ideal for very high viscosity or wall heat-sweep duties.

- Learn more: Hydrofoil Impeller

Pitch Blade Turbine (Versatile Workhorse) ⚙️

- Best for: General purpose mixing where you want a balance of flow and moderate shear.

- Typical RPM band: 60–250

- Viscosity range: ~1–2,000 cP

- Why choose it: Tunable (blade pitch/width), handles a wide range of batches well.

- Watchouts: Slightly higher power draw vs hydrofoil for same circulation.

- Learn more: Pitch Blade Turbine

Rushton (Gas–Liquid Dispersion) 🫧

- Best for: Aeration, hydrogenation, fermentation with sparged gas; strong local turbulence.

- Typical RPM band: 100–600

- Viscosity range: ~1–500 cP

- Why choose it: Excellent gas dispersion and mass transfer near the impeller.

- Watchouts: Needs baffles; higher shear may not suit shear-sensitive products.

- Learn more: Rushton Turbine

Anchor / Gate (Wall-Sweep for Viscous Duties) 🧲

- Best for: High-viscosity products, heat-sensitive media, wall heat-transfer enhancement.

- Typical RPM band: 10–80

- Viscosity range: ~2,000–100,000+ cP

- Why choose it: Sweeps/stirs at the wall, prevents dead zones, improves jacket/limpet performance.

- Watchouts: Not for intense dispersion; confirm motor torque and shaft stiffness.

- Learn more: Anchor Impeller · see vessels: SS Jacketed, Limpet-Coil Reactor

Paddle (Simple, Gentle, Reliable) 🪶

- Best for: Gentle blending, uniform circulation in low-to-moderate viscosities, rectangular tanks.

- Typical RPM band: 20–120

- Viscosity range: ~100–5,000 cP

- Why choose it: Simple construction, predictable hydraulics, easy maintenance.

- Watchouts: Lower pumping vs pitched blades; may need baffles for circulation.

- Learn more: Paddle Impeller

Concave Disc (Enhanced Flow/Shear Balance) 🥏

- Best for: Blend + mild dispersion where you need more pumping than a flat disc and smoother shear.

- Typical RPM band: 120–400

- Viscosity range: ~1–800 cP

- Why choose it: Improved flow vs flat disc; steadier power draw; good for dissolutions/emulsions.

- Watchouts: Not a substitute for true wall-sweep in viscous regimes.

- Learn more: Concave Disc Impeller

Helical Ribbon (Very High Viscosity / Pastes) 🌀

- Best for: Very high viscosity (creams, gels, pastes), where axial pumping at low RPM is critical.

- Typical RPM band: 5–50

- Viscosity range: >20,000 cP to paste-like

- Why choose it: Strong axial conveyance, uniform turnover, excellent with heating/cooling jackets.

- Watchouts: Higher torque requirements; confirm drive sizing and shaft support.

| Mixing Duty | Recommended Impeller Families | Notes |

|---|---|---|

| Bulk blending (low viscosity) | Hydrofoil, PBT | Highest flow per kW with hydrofoils |

| Solid suspension | Hydrofoil, PBT | Axial flow minimizes settling |

| Gas–liquid dispersion | Rushton | Requires baffles; strong local turbulence |

| High-viscosity & wall heat transfer | Anchor/Gate, Helical Ribbon | Low RPM, high torque; jacket/limpet friendly |

| Gentle blending / rectangular tanks | Paddle | Simple, predictable hydraulics |

| Blend + mild dispersion (mid-shear) | Concave Disc, PBT | Smoother shear than flat disc |

Applications & Industries We Serve

From bulk liquid blending to high-viscosity wall heat-transfer, SV Industries engineers agitators that match your process duty, vessel geometry, and energy targets. We support end-to-end projects across chemicals, pharma, food & beverage, paint/ink, water & wastewater, and minerals—with the right impeller, RPM, and power for each job. Explore core equipment on our Agitator and Reactor Vessel pages.

Where our agitators add value 💡

- Faster batch times & better homogeneity: Optimized circulation for consistent quality.

- Lower kW per result: High-efficiency impellers and VFD-tuned RPM save energy.

- Heat & mass-transfer boost: Better boundary-layer renewal in SS Jacketed and Limpet-Coil Reactors.

- Scale-up confidence: Correct selection of impeller family + shaft/drive ensures stable operation.

Industry + application matrix

| Industry | Typical Applications | Recommended Impellers | Notes |

|---|---|---|---|

| Chemicals | Dissolution, neutralization, crystallization, slurry suspension | Hydrofoil, PBT | High flow per kW for bulk blending; baffles reduce vortexing |

| Pharma & Biotech | Buffer/media prep, syrup blending, suspension, gentle shear tasks | Hydrofoil, PBT, Anchor (viscous) | Hygienic finishes (SS316L); stable RPM for batch repeatability |

| Food & Beverage | Emulsions, reconstitution, syrup/caramel, jacketed heating/cooling | PBT, Anchor / Helical | Wall-sweep improves heat transfer; gentle profiles protect texture |

| Paints, Inks & Coatings | Dispersion, shade development, viscosity build | PBT, Concave Disc | Tune shear vs flow; verify solids loading and solvent compatibility |

| Water & Wastewater | Flash mix, flocculation, chemical dosing, equalization | Hydrofoil (flash), Paddle/Anchor (flocculator) | Gentle mixing for fragile flocs; rectangular tanks suit paddle/gate |

| Minerals & Slurries | Solids suspension, leaching, conditioning | Hydrofoil, PBT | Axial flow minimizes settling; verify SG and particle size |

| Gas–Liquid Processes | Aeration, hydrogenation, fermentation (sparged) | Rushton | Requires baffles; high local turbulence for mass transfer |

| High-Viscosity / Heat-Sensitive | Creams, gels, pastes; wall heat-transfer | Anchor/Gate, Helical Ribbon | Low RPM, high torque; confirm drive sizing and support |

Typical vessels & process equipment we integrate with 🧪

- Reactors: Industrial Chemical Reactor, Chemical Process Reactor

- Thermal systems: SS Jacketed Vessel, Limpet-Coil Reactor Vessel

- Storage & utilities: Storage Tank

Ready to discuss your duty? 📞

Send tank dimensions, viscosity/SG, temperature, solids %, and mixing goal (blend/suspend/aerate/heat-transfer). We’ll propose impeller + RPM + kW matched to your industry and vessel.

→ Contact Us • View installs in our Gallery • Read more on the Blog.

Features of Our Agitator

Great agitators don’t just “spin”—they move the right volume of fluid with the least kW, run vibration-free, and last for years. Here are the engineering choices that separate a basic mixer from a production-ready SV Industries agitator.

1) Impeller Hydraulics — flow without wasted power 🌀

- Blade geometry & pitch: We choose between Hydrofoil (high flow per kW), Pitch Blade Turbine (versatile), Rushton (gas dispersion), Anchor/Paddle (wall-sweep) based on duty and viscosity.

- Axial vs radial flow: Axial for blending/suspension, radial for gas–liquid mass transfer.

- Baffles & tank geometry: Correct baffling converts swirl into top↔bottom circulation—faster mixing, lower kW.

2) Shaft, Hub & Critical Speed — quiet, stable operation 📐

- Critical speed margin: Shafts are sized so running RPM stays well below natural frequencies.

- Dynamic balancing: Rotating sets are balanced to minimize vibration, protecting seals/bearings.

- Torsional capacity: Hubs/couplings sized for startup torque and viscosity spikes.

3) Sealing & Bearing Housing — safety and uptime 🔒

- Mechanical seal vs stuffing box: Selected by pressure, temperature, media; food/pharma often prefer mechanical seals.

- Barrier/flush options: Prevents dry running, manages heat; extends seal life.

- Bearing housing alignment: Precision alignment reduces wear and noise.

4) Materials & Finish — built for your chemistry 🧪

- MOC: SS304/SS316L (standard), MS, and special alloys on request.

- Surface finish: Hygienic Ra for pharma/food; coatings for aggressive chemicals.

- Compatibility: We pair agitators with the right vessels: SS Jacketed Vessel, Limpet-Coil Reactor, Reactor Vessel.

5) Drives & Controls — efficiency you can tune ♻️

- IE3/IE4 motors + helical/inline gearboxes deliver torque efficiently.

- VFD control: Dial in RPM for startup, scale-up, and energy savings; reduces mechanical stress.

- Protection: IP ratings and overload protection suited to your environment.

6) Corrosion Resistance:

For industries handling corrosive materials, our agitators are coated or constructed with corrosion-resistant materials to ensure longevity.

| Design Feature | What it does | Buyer Benefit |

|---|---|---|

| Impeller profile (Hydrofoil/PBT/Rushton/Anchor) | Sets flow pattern & shear | Same result with **lower kW** and **shorter batch time** |

| Baffles matched to duty | Prevents vortexing; improves circulation | Reliable **solid suspension** and uniform mixing |

| Shaft sizing & balancing | Controls vibration; protects seals/bearings | **Less downtime**, longer component life |

| Seal selection (mechanical/stuffing) | Handles pressure/temperature/media safely | Leak-safe, compliant operation |

| IE3/IE4 + VFD | Efficient torque and RPM control | **Energy savings** and easy process tuning |

| MOC & surface finish | Chemical & hygiene compatibility | **Product quality** and regulatory confidence |

With these features, SV Industries has earned a reputation as the best agitator manufacturer in India, trusted by clients across industries for reliable and efficient solutions.

Engineer’s mini-checklist before sizing 🔧

- Media: Viscosity (cP), SG, temperature, solids %

- Duty: Blending, suspension, gas dispersion, heat-transfer, flocculation

- Vessel: Geometry, coil/jacket, nozzles, baffle plan

- Utilities: Available kW, preferred RPM control (VFD), environment/IP class

Use our tools to speed decisions: Vessel Volume & Level • Limpet-Coil Length

Explore impellers: Hydrofoil • PBT • Anchor • Rushton • Paddle • Concave Disc

Sizing Snapshot (Typical Specs & Ranges)

A quick, scannable guide to the usual ranges we engineer for. Exact values depend on tank geometry, baffles, viscosity/SG, temperature, and duty. For precise results, share your inputs or try our calculators: Vessel Volume & Level • Limpet-Coil Length.

Typical operating windows

| Duty / Use-case | Recommended Impeller | Viscosity Band | RPM Band* | Motor Power (kW)** | Notes (selection cues) |

|---|---|---|---|---|---|

| Bulk blending, dissolution (water-like) | Hydrofoil | ~1–500 cP | 80–300 | 0.75–22 | High flow per kW; add baffles to avoid vortexing |

| General mixing (moderate viscosity) | Pitch Blade Turbine | ~1–2,000 cP | 60–250 | 1.1–30 | Tunable blade pitch/width for flow vs shear |

| Gas–liquid dispersion (sparged) | Rushton | ~1–500 cP | 100–600 | 1.5–37 | Strong local turbulence; baffles mandatory |

| High-viscosity mixing & wall heat transfer | Anchor/Gate | ~2,000–100,000+ cP | 10–80 | 2.2–45 | Wall-sweep improves jacket/limpet performance |

| Gentle blending / rectangular tanks | Paddle | ~100–5,000 cP | 20–120 | 0.75–11 | Predictable hydraulics; consider baffles for circulation |

| Very high viscosity / pastes | Helical Ribbon | >20,000 cP | 5–50 | 7.5–55 | High torque; verify gearbox & shaft support |

*RPM depends on tank size, liquid height, and baffle plan. **Power ranges are indicative for common tank sizes (≈1–50 kL). We’ll size to your exact vessel on request.

Fast reference — vessel & drivetrain ranges

| Parameter | Typical Range | Selection Tip |

|---|---|---|

| Tank Working Volume | ≈ 1,000–50,000+ L (1–50+ kL) | Height-to-diameter ≈ 1.0–1.5 is common for top-entry |

| Impeller Count | 1–3 | Multiple impellers for tall tanks (liquid height > 1.6× tank dia) |

| Shaft Diameter | ~25–120 mm | Size for critical-speed margin & startup torque |

| Motor Efficiency Class | IE3 / IE4 | Pair with VFD for energy savings and process tuning |

| Gearbox Type | Helical inline/parallel; Planetary (high torque) | Planetary suits viscous, low-RPM duties (anchor/helical) |

| Seal Type | Stuffing box; Single/Double mechanical | Double seals for hazardous/abrasive media or vacuum |

| Materials (MOC) | SS304 / SS316L / MS; special alloys | Match chemistry & hygiene; see SS Jacketed / Limpet-Coil |

Typical vessels & process equipment we integrate with 🧪

- Reactors: Industrial Chemical Reactor, Chemical Process Reactor

- Thermal systems: SS Jacketed Vessel, Limpet-Coil Reactor Vessel

- Storage & utilities: Storage Tank

Ready to discuss your duty? 📞

Send tank dimensions, viscosity/SG, temperature, solids %, and mixing goal (blend/suspend/aerate/heat-transfer). We’ll propose impeller + RPM + kW matched to your industry and vessel.

→ Contact Us • View installs in our Gallery • Read more on the Blog.

Why Choose Us as the Best Agitator Manufacturer in India?

At SV Industries, we take pride in being recognized as one of the best agitator manufacturers in India. Here’s what sets us apart:

1. Advanced Technology:

Our agitators are built using high-grade materials that ensure durability and longevity, even under demanding industrial conditions.

2. Experienced Team:

With optimized blade designs and precision engineering, our agitators consume less power while delivering superior performance.

3. Custom Solutions:

Every industry has unique requirements, and we offer fully customizable agitators to suit your specific needs, including size, type, and configuration.

4. Quality Assurance:

Our advanced technology ensures uniform and efficient mixing, reducing process time and improving product quality.

5. Affordable Pricing:

Designed for minimal downtime, our agitators feature easy-to-replace components and straightforward maintenance procedures.

Industrial Agitator Manufacturers in India

SV Industries is a leading Industrial Agitator Manufacturer in India, based in Ahmedabad, Gujarat. We specialize in providing high-quality agitators designed to meet the diverse needs of industries such as chemicals, pharmaceuticals, food processing, and more. Our industrial agitators are engineered to offer superior mixing performance, durability, and efficiency in various processes, including blending, stirring, and emulsifying.

As trusted agitator manufacturers, we use the latest technology and premium-grade materials to ensure that every agitator is built to last and perform optimally in challenging environments. Whether you need a standard or custom-built agitator, we provide solutions tailored to your specific requirements.

At SV Industries, our team of skilled engineers works closely with clients to design and manufacture chemical reactors and storage tanks that meet industry standards. Our commitment to quality, precision, and customer satisfaction has made us a preferred choice for businesses across India.

Choose SV Industries for all your industrial agitator needs. As one of the top manufacturers in the country, we are dedicated to delivering reliable, cost-effective solutions that help improve your production processes and overall operational efficiency. Connect with us today to learn more about our range of products and services.

Top Agitator Manufacturer in India

SV Industries is recognized as one of the top agitator manufacturers in India, specializing in the design and production of high-quality industrial agitators for a variety of industries. Located in Ahmedabad, Gujarat, we have earned a reputation for delivering superior agitators that offer exceptional mixing performance and durability.

Our team of experienced engineers ensures that every agitator is crafted with the latest technology and best-in-class materials to meet the unique needs of industries such as chemical, pharmaceutical, food processing, and more. As a leading manufacturer of agitators, we understand the importance of efficiency, reliability, and precision in mixing processes, and we provide tailored solutions to meet your specific requirements.

At SV Industries, we not only focus on manufacturing industrial agitators, but also offer integrated solutions with our chemical reactors and storage tanks. Our products are built to withstand demanding applications and help optimize production processes.

As one of the top manufacturers in India, we pride ourselves on our commitment to quality and customer satisfaction. Partner with SV Industries for innovative and cost-effective agitator solutions that drive operational excellence. Get in touch with us today to explore our wide range of products and services.

Best Agitator Supplier in India

SV Industries is the best agitator supplier in India, offering top-quality industrial agitators designed to meet the diverse needs of various industries. Based in Ahmedabad, Gujarat, we are known for delivering reliable, high-performance agitators that provide efficient mixing, blending, and emulsifying solutions for industries such as chemicals, pharmaceuticals, food processing, and more.

As a trusted agitator supplier, we focus on providing innovative and durable products that are engineered to deliver optimal performance in demanding environments. Our industrial agitators are manufactured using advanced technology and high-quality materials, ensuring long-lasting performance and minimal maintenance. We cater to both standard and custom-designed agitators, allowing us to meet the specific needs of our clients with precision.

At SV Industries, our commitment to excellence goes beyond just supplying agitators. We also provide chemical reactors and storage tanks, ensuring that your mixing and production needs are fully met. As the best supplier in the industry, we focus on customer satisfaction, delivering solutions that improve efficiency and productivity.

Partner with SV Industries for all your agitator requirements, and experience the reliability and performance that comes with being a leading supplier in India. Reach out to us today for a consultation and discover how our products can enhance your business operations.

India Industrial Agitator Maker

SV Industries is a prominent industrial agitator maker in India, dedicated to providing high-quality agitators for a wide range of industries, including chemical, pharmaceutical, food processing, and more. Based in Ahmedabad, Gujarat, we specialize in the design and manufacture of advanced industrial agitators that are built to deliver exceptional mixing, stirring, and blending performance.

As a trusted agitator maker, we focus on delivering solutions that are not only durable but also energy-efficient and cost-effective. Our team of skilled engineers uses cutting-edge technology and premium materials to ensure that each agitator meets the highest industry standards. Whether you require a standard model or a custom-built solution, we have the expertise to meet your exact specifications.

In addition to manufacturing industrial agitators, we also offer chemical reactors and storage tanks designed to complement your production processes. As a leading agitator maker in India, SV Industries is committed to delivering reliable and innovative solutions that help businesses optimize their operations.

Choose SV Industries for all your industrial agitator needs and experience the quality and performance that comes from partnering with one of India’s top agitator makers. Contact us today to learn more about our products and services.

Custom Agitator Fabrication India

SV Industries is a leading provider of custom agitator fabrication in India, specializing in the design and manufacture of tailored industrial agitators that meet the unique requirements of various industries. Located in Ahmedabad, Gujarat, we offer innovative solutions for businesses in sectors like chemicals, pharmaceuticals, food processing, and more.

As experts in custom agitator fabrication, we work closely with clients to understand their specific mixing, blending, and stirring needs. Our skilled engineers design agitators that are optimized for performance, durability, and energy efficiency. Whether you need custom agitators for small-scale operations or large industrial applications, we provide solutions that meet your precise specifications.

At SV Industries, we use advanced technology and high-quality materials in our agitator fabrication process to ensure top-notch products. We also offer a range of additional services, including the manufacture of chemical reactors and storage tanks, creating a comprehensive solution for all your industrial needs.

As a trusted name in custom agitator fabrication in India, we are committed to delivering products that exceed expectations. Partner with SV Industries for all your agitator needs and experience the difference in quality, precision, and reliability. Contact us today to discuss your requirements and receive expert guidance on the best solutions for your business.

Agitator Equipment Companies India

SV Industries is one of the leading agitator equipment companies in India, specializing in the manufacturing of high-performance industrial agitators for a variety of applications across industries like chemicals, pharmaceuticals, food processing, and more. Based in Ahmedabad, Gujarat, we have built a reputation for delivering durable, efficient, and cost-effective agitator equipment tailored to the specific needs of our clients.

As a top-tier agitator equipment company, we provide an extensive range of industrial agitators, including customized solutions for specialized mixing, blending, and emulsifying processes. Our team of experts designs each piece of agitator equipment with precision, using the latest technology and premium materials to ensure optimal performance and longevity in demanding environments.

SV Industries is dedicated to being more than just an agitator equipment company – we are your reliable partner for complete mixing solutions. Along with agitators, we also manufacture chemical reactors and storage tanks to support your entire production process.

Choose SV Industries for all your agitator equipment needs. As one of the leading agitator companies in India, we focus on providing solutions that improve operational efficiency and meet the highest industry standards. Get in touch with us today to explore our range of products and services.

India Agitator System Providers

SV Industries is a trusted name among agitator system providers in India, offering high-quality industrial agitators that cater to the needs of various industries such as chemicals, pharmaceuticals, food processing, and more. Based in Ahmedabad, Gujarat, we specialize in providing efficient and reliable agitator systems designed to optimize mixing, blending, and stirring processes.

As leading agitator system providers, we ensure that our agitator systems are crafted using the latest technology and the best materials, ensuring durability and long-lasting performance. Our team of skilled engineers works closely with clients to design customized solutions that meet specific operational requirements, making us a preferred choice for businesses across India.

In addition to agitator systems, SV Industries also manufactures complementary products like chemical reactors and storage tanks, providing comprehensive solutions for industrial mixing needs. As a prominent agitator system provider, we are committed to offering innovative, energy-efficient, and cost-effective solutions that enhance production processes and operational efficiency.

Partner with SV Industries for all your agitator system needs. With years of experience and a focus on quality, we deliver products that meet the highest industry standards. Contact us today to learn more about how we can support your business with advanced agitator systems.

High-Quality Agitators India

SV Industries is a renowned manufacturer of high-quality agitators in India, specializing in producing durable and efficient industrial agitators for a variety of industries. Based in Ahmedabad, Gujarat, we provide state-of-the-art agitators designed to meet the rigorous demands of industries like chemicals, pharmaceuticals, food processing, and more.

Our commitment to quality ensures that every industrial agitator is built using advanced technology and premium materials to provide optimal performance and longevity. Whether you need a standard agitator or a custom-built solution, we deliver products that are engineered to improve mixing, blending, and emulsifying processes, making us a trusted name in the industry.

At SV Industries, we focus on producing high-quality agitators that offer exceptional reliability and energy efficiency. In addition to agitators, we also manufacture complementary products such as chemical reactors and storage tanks to provide comprehensive solutions for your industrial mixing and production needs.

Choose SV Industries for your high-quality agitator requirements. As one of the leading manufacturers in India, we guarantee top-notch products that enhance operational efficiency and meet the highest industry standards. Contact us today to learn more about our range of agitators and other industrial solutions.

Agitator Design and Manufacturing India

SV Industries is a leading company specializing in agitator design and manufacturing in India, offering customized solutions for industries such as chemicals, pharmaceuticals, food processing, and more. Based in Ahmedabad, Gujarat, we are committed to providing innovative and efficient agitators tailored to meet the specific needs of your business operations.

Our expert team specializes in the design and manufacturing of industrial agitators that ensure optimal mixing, blending, and stirring performance. Using advanced technology and high-quality materials, we design agitators that are energy-efficient, durable, and reliable, ensuring long-lasting performance in even the most demanding environments.

At SV Industries, we understand that each industry and application has unique requirements. Therefore, our agitator design process is highly customizable to ensure that your specific needs are met. We also offer integrated solutions with other products such as chemical reactors and storage tanks, providing a comprehensive approach to your production processes.

As a trusted name in agitator design and manufacturing, we are dedicated to delivering top-quality products that meet industry standards and improve your operational efficiency. Partner with SV Industries for all your agitator needs, and experience superior design, performance, and reliability. Contact us today to discuss your requirements.

Reliable Agitator Exporter India

SV Industries is a reliable agitator exporter in India, known for supplying high-quality industrial agitators to markets worldwide. Based in Ahmedabad, Gujarat, we have earned a strong reputation for delivering durable and efficient agitators designed for various industries, including chemicals, pharmaceuticals, food processing, and more.

As a trusted agitator exporter, we ensure that each industrial agitator is crafted using the best materials and advanced technology to meet international quality standards. Our agitators are designed for maximum efficiency, durability, and energy savings, making them ideal for diverse mixing, blending, and emulsifying applications across the globe.

SV Industries takes pride in its ability to deliver custom-designed agitators that meet specific client needs, while also providing complementary products such as chemical reactors and storage tanks. With a strong focus on customer satisfaction and global expansion, we ensure that our products are delivered on time and with the highest level of quality.

As a reliable exporter of agitators, SV Industries is committed to building long-lasting partnerships and providing cost-effective, efficient solutions for businesses worldwide. Get in touch with us today to discuss how we can serve your international agitator requirements and deliver world-class products tailored to your needs.

Agitator Solutions In India

SV Industries is a leading provider of agitator solutions in India, specializing in the design, manufacture, and supply of high-performance industrial agitators for a wide range of applications. Based in Ahmedabad, Gujarat, we are committed to delivering innovative and reliable agitators that cater to industries such as chemicals, pharmaceuticals, food processing, and more.

Our agitator solutions are designed to optimize mixing, blending, and stirring processes, ensuring that your production operations run smoothly and efficiently. Whether you require a standard agitator or a custom-built solution, we offer tailored designs that meet your specific needs. Our industrial agitators are built using advanced technology and premium materials to ensure durability, energy efficiency, and long-lasting performance.

At SV Industries, we go beyond just providing agitator solutions. We also offer complementary products like chemical reactors and storage tanks, creating a comprehensive solution for all your industrial mixing and production requirements. Our team of experts works closely with clients to provide end-to-end solutions that improve operational efficiency and meet industry standards.

Choose SV Industries for your agitator solutions in India. With our experience and commitment to quality, we guarantee reliable, cost-effective products that enhance your production processes. Contact us today to learn more about our products and services.

Agitator Technology India

SV Industries is at the forefront of agitator technology in India, offering cutting-edge solutions for industrial mixing, blending, and stirring applications. Based in Ahmedabad, Gujarat, we specialize in the design and manufacture of industrial agitators that incorporate the latest technological advancements to ensure optimal performance and efficiency.

Our agitator technology is built using state-of-the-art systems that ensure high durability, energy efficiency, and superior mixing results. Whether for chemical reactors, food processing, or pharmaceuticals, our agitators are designed to meet the unique needs of each industry, providing solutions that streamline operations and improve production quality.

SV Industries is committed to staying ahead of industry trends, ensuring our agitators are built with the most reliable and innovative technology available. Our engineers work closely with clients to develop custom agitator solutions that meet specific process requirements, providing greater efficiency and cost-effectiveness.

With a focus on continuous innovation and improvement, SV Industries brings agitator technology that helps businesses enhance their operations. Trust SV Industries for your agitator needs and experience the benefits of advanced technology, superior quality, and customized solutions. Contact us today to learn more about our offerings.

Mixing Agitator Manufacturer India

SV Industries is a leading mixing agitator manufacturer in India, specializing in the design and production of high-quality industrial mixing agitators for a variety of industries, including chemicals, pharmaceuticals, food processing, and more. Based in Ahmedabad, Gujarat, we are known for delivering reliable, efficient, and durable agitators that optimize the mixing, blending, and emulsifying processes in diverse industrial applications.

As a trusted mixing agitator manufacturer, we use advanced technology and premium materials to create agitators that ensure superior performance, energy efficiency, and longevity. Whether you need a standard mixing agitator or a customized solution tailored to your specific requirements, SV Industries has the expertise to deliver the ideal product for your needs.

Our team of skilled engineers works closely with clients to design mixing agitators that are perfect for various mixing applications, ensuring maximum efficiency and reduced operational costs. In addition to mixing agitators, we also offer chemical reactors and storage tanks, providing a comprehensive solution for your industrial mixing and production needs.

Choose SV Industries as your trusted mixing agitator manufacturer in India. We are committed to providing top-quality, cost-effective products that enhance your production processes. Contact us today to explore our range of products and services.

Agitator for Chemical Industries India

SV Industries is a leading manufacturer of high-quality agitators for chemical industries in India, providing advanced solutions for efficient mixing, blending, and chemical reactions. Based in Ahmedabad, Gujarat, we specialize in designing and manufacturing industrial agitators that meet the rigorous demands of the chemical sector, ensuring optimal performance and superior reliability in diverse processes.

As a trusted agitator manufacturer for chemical industries, SV Industries designs custom solutions that improve process efficiency, enhance product quality, and reduce operational costs. Our chemical agitators are built using premium materials and the latest technology to ensure long-lasting performance in challenging chemical environments. Whether you require a standard agitator or a specialized solution, we offer products that can be tailored to your specific needs.

Our agitators for the chemical industry are engineered for superior mixing, ensuring uniformity and effective chemical reactions. In addition to chemical agitators, SV Industries also offers complementary products like chemical reactors and storage tanks, providing a comprehensive solution for the chemical manufacturing process.

Choose SV Industries for your agitator for chemical industries needs. With years of expertise, commitment to quality, and customer satisfaction, we guarantee reliable, cost-effective, and efficient solutions to enhance your operations. Contact us today to learn more about how our products can support your chemical manufacturing processes.

Stainless Steel Agitators India

SV Industries is a renowned manufacturer of stainless steel agitators in India, specializing in providing high-quality, durable, and efficient industrial agitators for various industries such as chemicals, pharmaceuticals, food processing, and more. Based in Ahmedabad, Gujarat, we design and produce stainless steel agitators that are engineered to deliver optimal mixing, blending, and emulsifying performance.

Our stainless steel agitators are known for their superior corrosion resistance, durability, and strength, making them ideal for use in demanding environments where hygiene and longevity are critical. Manufactured using the finest stainless steel materials, our agitators ensure that your mixing processes are efficient, energy-efficient, and cost-effective, while maintaining high-quality standards.

As a trusted manufacturer of stainless steel agitators, we offer both standard and custom-built solutions tailored to meet the specific needs of your business. Whether you need agitators for chemical reactors, storage tanks, or any other industrial applications, we can design a solution that fits your exact requirements.

Choose SV Industries for your stainless steel agitators in India. With years of experience and a focus on quality, we are committed to providing reliable, high-performance products that enhance your industrial operations. Contact us today to explore our range of agitators and find the perfect solution for your needs.

India Agitator Engineering Services

SV Industries offers specialized agitator engineering services in India, providing tailored solutions for industries requiring efficient mixing, blending, and stirring. Based in Ahmedabad, Gujarat, we are a trusted name in designing and manufacturing industrial agitators that cater to a range of sectors, including chemicals, pharmaceuticals, food processing, and more.

Our agitator engineering services include the complete process of designing, developing, and optimizing agitators to meet your specific operational needs. From initial consultation to installation and maintenance, we ensure that our agitators provide maximum performance, durability, and efficiency. Our team of experienced engineers works closely with clients to develop customized solutions that address their unique mixing challenges and improve overall production processes.

At SV Industries, we combine advanced agitator engineering technologies with industry expertise to deliver high-quality agitators that perform reliably in demanding environments. We also offer additional services, including the design of chemical reactors and storage tanks, ensuring a comprehensive solution for your industrial mixing needs.

Choose SV Industries for your agitator engineering services in India. With a focus on quality, customer satisfaction, and innovation, we provide cutting-edge solutions that enhance your operations and help you achieve optimal results. Contact us today to learn more about how our engineering services can support your business.

Agitator Maintenance in India

SV Industries offers reliable agitator maintenance services in India, ensuring that your industrial agitators continue to perform at their best for years. Based in Ahmedabad, Gujarat, we specialize in providing comprehensive maintenance solutions for a wide range of industries, including chemicals, pharmaceuticals, food processing, and more. Our focus is on ensuring the longevity, efficiency, and optimal performance of your agitators, keeping your production processes running smoothly.

Our agitator maintenance services include routine inspections, repairs, and upgrades, as well as troubleshooting any issues that may arise during operations. With our expert team of engineers, we ensure that your agitators are running at peak efficiency, reducing downtime and preventing costly disruptions in your operations. Whether it’s for routine upkeep or emergency repairs, SV Industries offers tailored maintenance solutions to meet the specific needs of your equipment.

In addition to agitator maintenance, we also provide services for other industrial equipment, such as chemical reactors and storage tanks, ensuring that your entire production system is well-maintained.

Choose SV Industries for agitator maintenance services in India. With our expertise and commitment to quality, we help extend the life of your equipment, optimize operational efficiency, and ensure that your business runs without interruptions. Contact us today to discuss your maintenance needs.

India Agitator Industry Expert

SV Industries is a trusted agitator industry expert in India, specializing in the design, manufacture, and maintenance of high-performance industrial agitators. Based in Ahmedabad, Gujarat, we bring years of experience and in-depth knowledge to provide cutting-edge solutions for industries such as chemicals, pharmaceuticals, food processing, and more.

As agitator industry experts, we offer a comprehensive range of services, including the development of custom-designed agitators that cater to specific mixing, blending, and stirring needs. Our team of engineers uses advanced technology and premium materials to create agitators that deliver superior performance, reliability, and energy efficiency. We understand the unique challenges each industry faces, which is why we provide tailored solutions that optimize your production processes.

In addition to our agitator manufacturing expertise, SV Industries also offers valuable insights on system design, operational optimization, and maintenance best practices. We ensure that our agitators are built to meet the highest quality standards, providing long-term value and minimal downtime.

Choose SV Industries as your agitator industry expert in India. With our industry-leading knowledge and commitment to innovation, we deliver reliable, cost-effective solutions that help businesses enhance their operations and achieve maximum efficiency. Contact us today to explore how we can assist you with your agitator needs.

Agitator System Integration India

SV Industries is a leading provider of agitator system integration in India, offering comprehensive solutions for the seamless integration of industrial agitators into your production processes. Based in Ahmedabad, Gujarat, we specialize in designing and integrating customized agitator systems that cater to various industries, including chemicals, pharmaceuticals, food processing, and more.

As experts in agitator system integration, we understand the importance of aligning agitators with your specific operational requirements. Our team works closely with clients to ensure smooth system integration, improving the overall performance, efficiency, and reliability of your mixing, blending, and stirring processes. From the initial design phase to installation and testing, we provide end-to-end services to ensure that your agitator system functions seamlessly within your existing infrastructure.

SV Industries leverages advanced technology and premium materials to build agitator systems that are energy-efficient, durable, and easy to maintain. We also offer ongoing support and maintenance services to keep your agitator system running at peak efficiency.

Choose SV Industries for agitator system integration in India. With years of experience and a commitment to quality, we ensure that your agitator systems are tailored to your needs and deliver maximum value. Contact us today to discuss how we can help optimize your industrial operations with advanced system integration solutions.

Process Agitator India

SV Industries is a trusted manufacturer of high-quality process agitators in India, specializing in delivering efficient and reliable agitators for industrial applications across a range of sectors, including chemicals, pharmaceuticals, food processing, and more. Based in Ahmedabad, Gujarat, we design and produce process agitators that optimize mixing, blending, and emulsifying processes, ensuring that your production systems operate smoothly and efficiently.

Our process agitators are engineered to meet the specific needs of various industries, providing superior performance and reliability in mixing fluids, solids, and gases. Whether you require a standard process agitator or a customized solution designed to fit your exact specifications, SV Industries offers versatile products that improve your operational efficiency and enhance the quality of your final product.

At SV Industries, we use the latest technology and high-quality materials to manufacture process agitators that are durable, energy-efficient, and easy to maintain. We also offer complementary products such as chemical reactors and storage tanks, providing a comprehensive solution for your industrial mixing and production needs.

Choose SV Industries for all your process agitator requirements in India. With a focus on innovation, quality, and customer satisfaction, we deliver products designed to meet the highest industry standards. Contact us today to learn more about how our process agitators can improve your production processes.

High Efficiency Agitator Manufacturer in India

SV Industries is a leading high-efficiency agitator manufacturer in India, known for providing innovative and reliable industrial agitators that enhance the mixing, blending, and emulsifying processes in various industries. Based in Ahmedabad, Gujarat, we specialize in designing and manufacturing agitators that deliver optimal performance while ensuring energy efficiency and cost savings for your production operations.

As a trusted high-efficiency agitator manufacturer, we focus on designing products that improve operational efficiency and reduce energy consumption. Our industrial agitators are built using advanced technology and premium materials to ensure durability, long-lasting performance, and minimal maintenance, making them ideal for demanding environments such as chemical, pharmaceutical, and food processing industries.

SV Industries offers a range of high-efficiency agitators that can be customized to meet the specific needs of your business. Whether you’re looking for standard agitators or a custom-built solution, our team of experts works closely with you to ensure the ideal product for your mixing and blending needs.

Choose SV Industries as your high-efficiency agitator manufacturer in India. With a commitment to quality, customer satisfaction, and innovation, we guarantee products that help improve your operational efficiency and meet the highest industry standards. Contact us today to learn more about our agitators and how we can support your business needs.

Industrial Stirrer Manufacturer in India

SV Industries is a leading industrial stirrer manufacturer in India, specializing in providing high-quality stirrers designed for efficient mixing, blending, and stirring in various industries. Based in Ahmedabad, Gujarat, we manufacture industrial stirrers that are engineered to meet the unique requirements of sectors such as chemicals, pharmaceuticals, food processing, and more.

As a trusted industrial stirrer manufacturer, we focus on delivering products that ensure superior performance, reliability, and energy efficiency. Our stirrers are built using the latest technology and premium materials, ensuring durability and long-lasting functionality even in the most demanding environments. Whether you need a standard stirrer or a custom-built solution tailored to your specific mixing needs, we offer flexible options to fit your business requirements.

SV Industries provides a range of industrial stirrers that offer excellent mixing capabilities, improving your production processes and helping achieve better product quality. In addition to stirrers, we also offer complementary products such as agitators, chemical reactors, and storage tanks, providing a complete solution for your industrial mixing needs.

Choose SV Industries for your industrial stirrer requirements in India. With our expertise in manufacturing high-performance equipment, we are committed to delivering reliable, efficient, and cost-effective solutions to help optimize your production. Contact us today to learn more about our industrial stirrers and how we can support your business needs.

Agitator Frequently Asked Question (FAQs)

What industries can use your agitators?

Our agitators are designed for a wide range of industries, including chemical processing, pharmaceuticals, food and beverage, water treatment, and paints and coatings. They are versatile and can be customized to meet specific industrial needs.

How do I choose the right agitator for my application?

Choosing the right agitator depends on factors like the type of fluid, viscosity, tank size, and process requirements. Our experts can guide you in selecting the best agitator for your specific needs.

Are your agitators energy efficient?

Yes, our agitators are designed with energy efficiency in mind. Optimized blade designs and precision engineering ensure minimal power consumption while delivering superior performance.

Can your agitators handle corrosive materials?

Absolutely. Our agitators are made with corrosion-resistant materials or coatings, making them suitable for handling corrosive substances in industries like chemicals and water treatment.

Do you offer customization options for agitators?

Yes, we provide fully customizable agitators tailored to your specific requirements, including size, type, configuration, and materials.

What is the maintenance requirement for your agitators?

Our agitators are designed for ease of maintenance, with easy-to-replace components and straightforward servicing procedures to minimize downtime.

Why should I choose SV Industries as my agitator manufacturer?

SV Industries is renowned for its high-quality, reliable, and efficient agitators. We prioritize customer satisfaction and provide customized solutions to ensure optimal performance for your operations.

What materials are used in the construction of your agitators?

Our agitators are constructed using high-grade materials such as stainless steel, carbon steel, and corrosion-resistant alloys, depending on the application and industry requirements.

Can your agitators be used in high-temperature applications?

Yes, our agitators are designed to withstand high temperatures and are suitable for applications involving heated mixtures or processes